Cooler structure optimization method suitable for an arc wind tunnel

An optimization method and cooler technology, applied in the fields of instruments, electrical digital data processing, special data processing applications, etc., can solve the problems of cumbersome, complex calculation of cooler capacity, etc., to improve heat exchange efficiency, optimize heat exchange structure characteristics, The effect of fast and efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

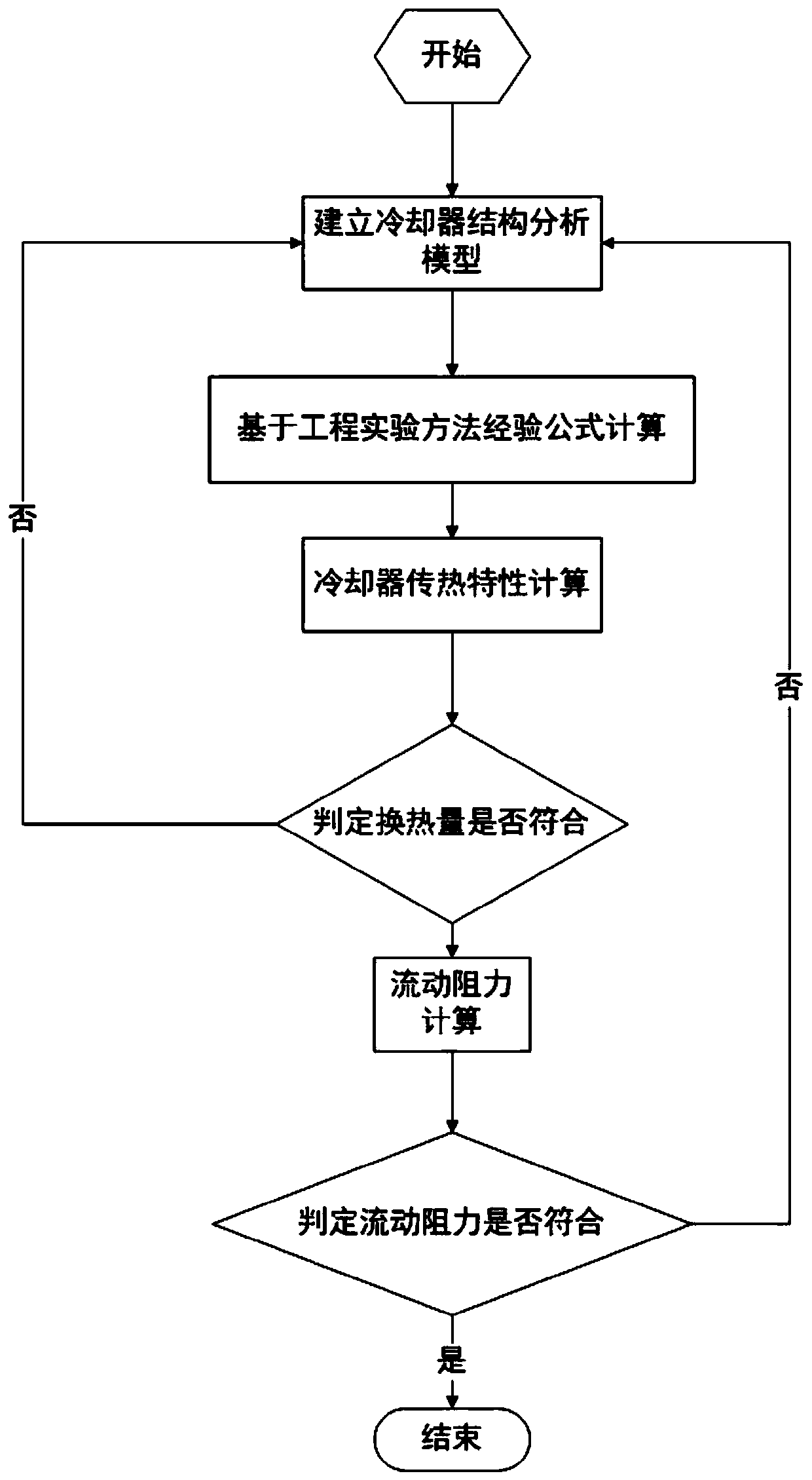

[0033] Attached below figure 1 The present invention will be described in detail.

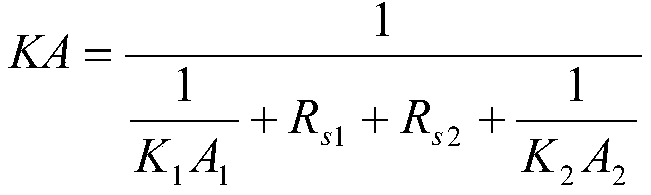

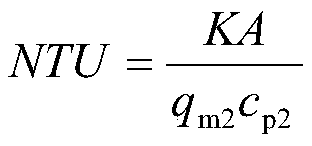

[0034] The heat exchange coefficient of gas is small, usually 10W / (m 2 ·K)~30W / (m 2 K) or so, so a larger heat transfer area is generally required to achieve sufficient heat transfer. The state parameters of high-temperature gas change greatly during the cooling process. In the early stage of heat exchange, the airflow temperature is high, the heat exchange temperature difference is large, and the total heat exchange heat is relatively large. However, at this time, the gas density is low, the flow velocity is high, and the flow resistance is large. Therefore, the design should consider reducing the flow velocity of the gas as much as possible. As the heat exchange process proceeds, the temperature of the gas gradually decreases and the density increases. In the later stage of heat exchange, the temperature drops to about 500K, and the heat exchange temperature difference with the cooling wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com