High-temperature push-pull fatigue test clamp for hollow round rod test piece

A hollow round bar, fatigue test technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of forming temperature gradient, construction, unable to hold hollow round bar specimens, etc., to reduce heat transfer and reduce fixture temperature. , the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention is mainly designed for a high-temperature fatigue fixture with a cooling channel suitable for a hollow round bar test piece. In fact, during the test, the whole set of fixtures includes two fixtures of the present invention, which are divided into upper fixtures and lower fixtures. The general diagram of complete installation is shown in Figure 9 . First assemble the upper and lower fixtures separately:

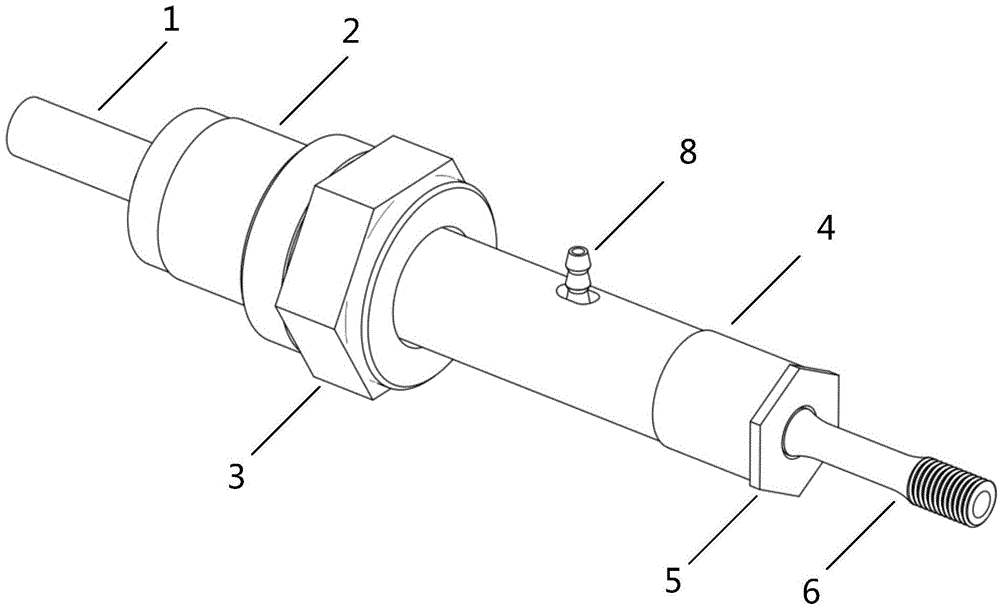

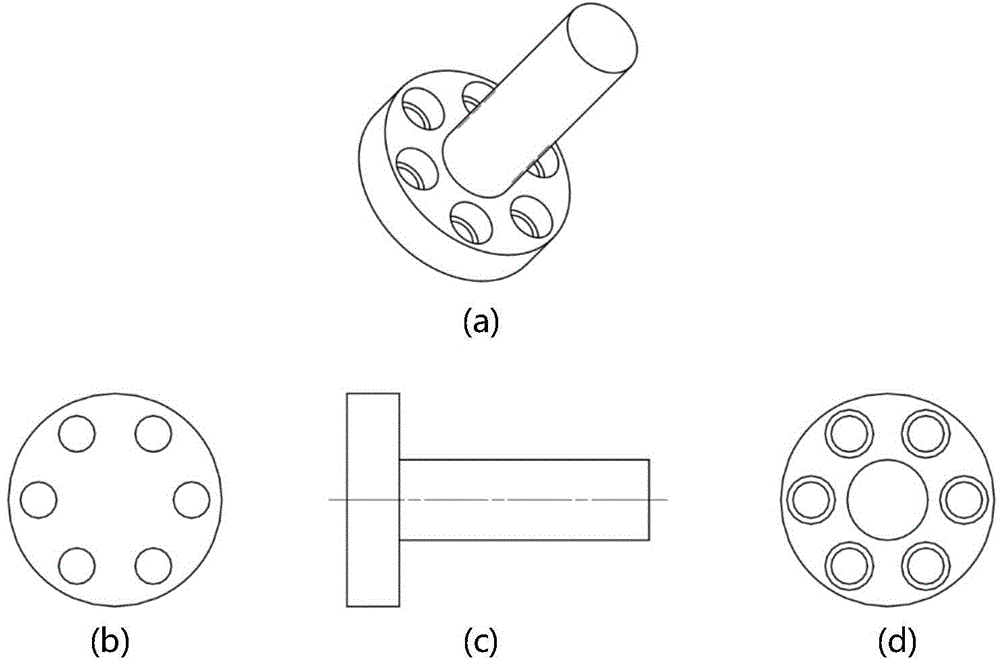

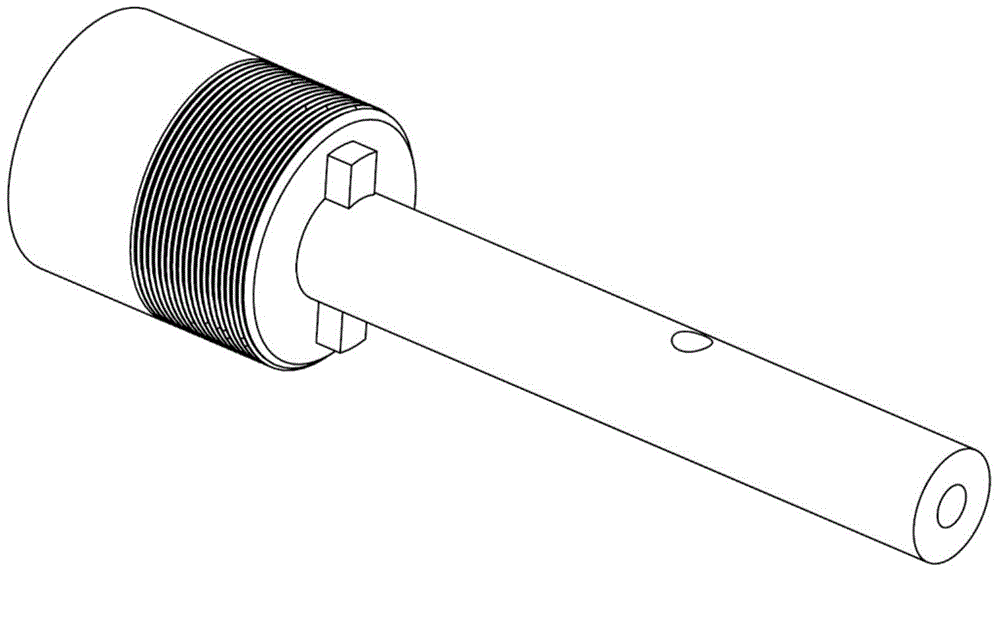

[0031] Such as figure 1 , 2 , As shown in 3, 4, 5, 6, 7, and 10, first assemble the fixture. Connect and tighten the joint 1 and the thick end of the connecting rod 2 through six countersunk bolts 7, and then insert the sleeve 4 into one end of the hollow rod of the connecting rod 2. The two small teeth fit together, so that unnecessary rotation can be prevented, and at the same time, the relative positions of the connecting rod 2 and the sleeve 4 can be accurately positioned to facilitate subsequent installation of the cooler joint 8. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com