Instant milling force prediction method in variable-curvature curved surface side milling process

A technology of instantaneous milling force and prediction method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as inaccurate calculation results of feed per tooth, a large number of mathematical calculations, and inability to obtain NC codes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

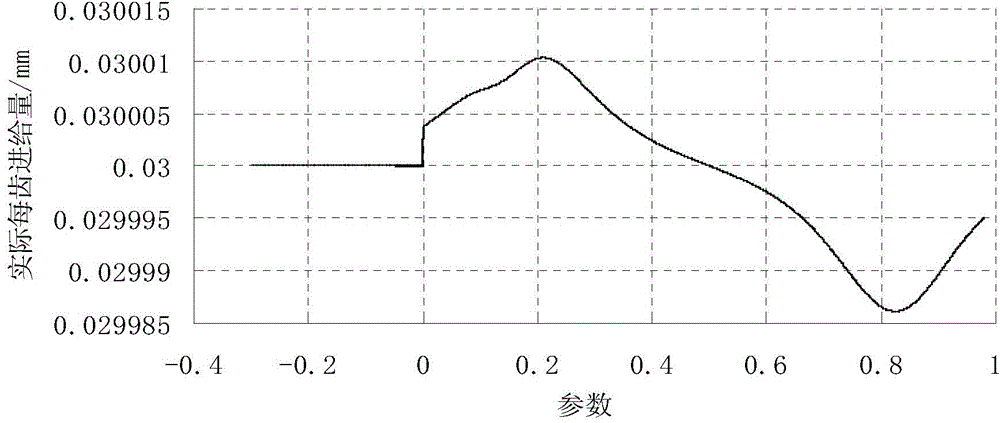

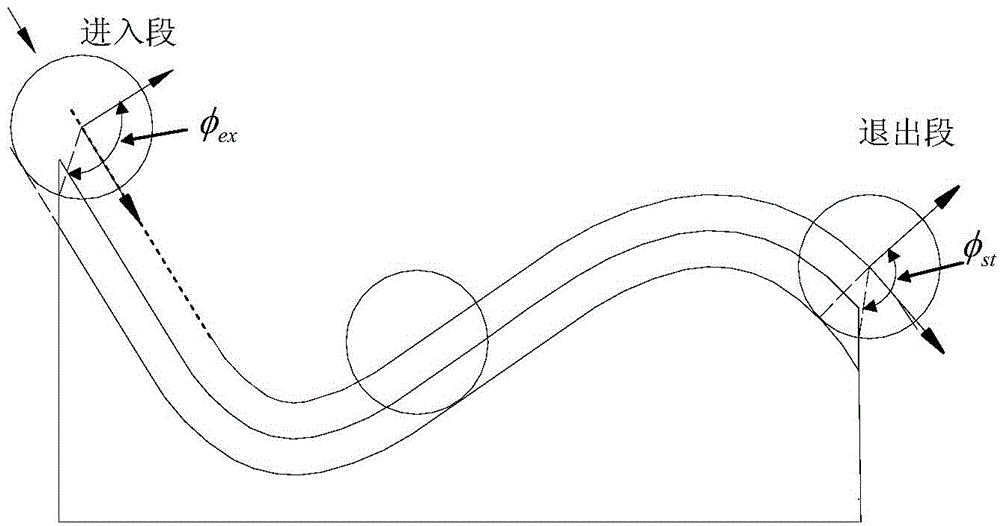

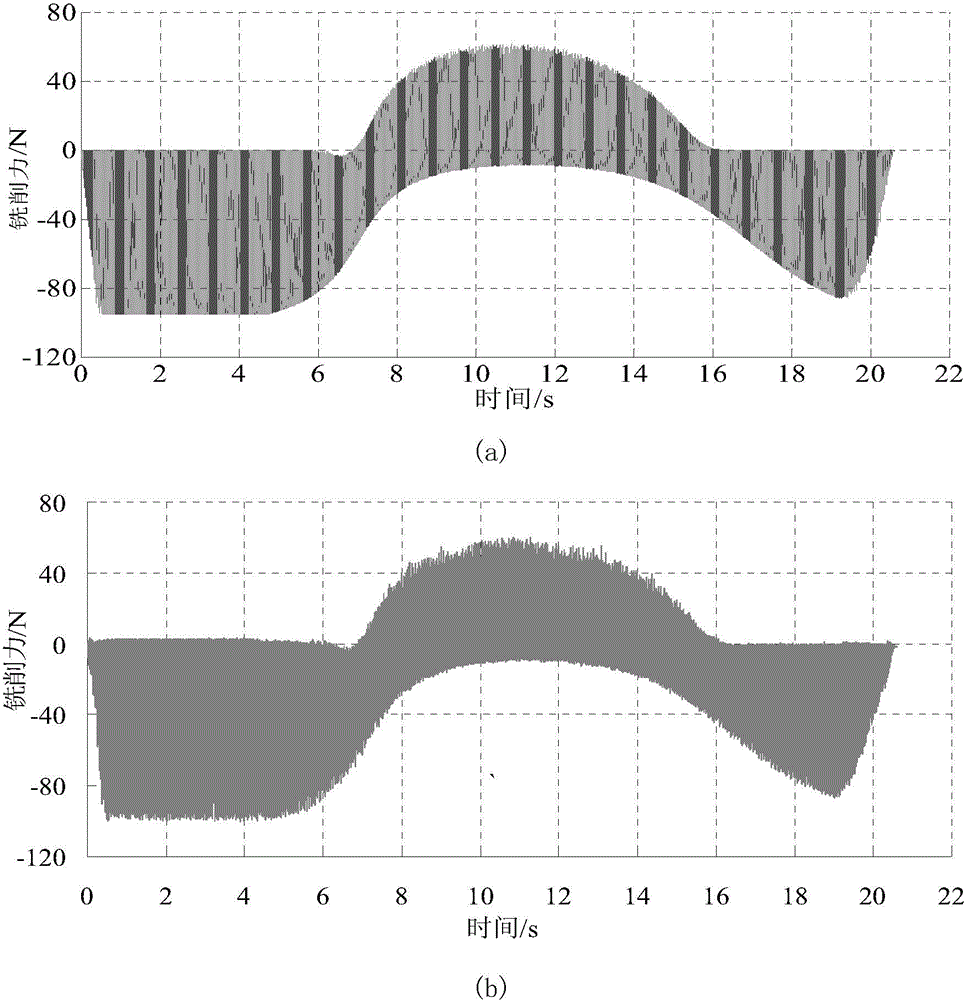

[0122] (1) Select tool radius R=5mm, helix angle β=35°, number of cutter teeth N f =4, the Al6061 material is processed on a three-coordinate vertical milling machine; the spindle speed n r =3000r / min, axial depth of cut a p = 2mm, nominal radial depth of cut a e =3mm, nominal feed per tooth f z =0.03mm / r, down milling; sampling point parameter interval Δu=0.00002; the parameter equation of workpiece contour curve after processing is:

[0123] x(u)=50u, y(u)=-80u-0.2≤u≤0;

[0124] x(u)=75u+15u 2 -10u 3 , y(u)=-120u+360u 2 -240u 3 0≤u≤1.

[0125] The left boundary of the blank is:

[0126] x=-10.

[0127] The right boundary of the blank is:

[0128] x=80.

[0129] (2) Calculate the corresponding tool path curve parameter u when the tool starts cutting material 0 =-0.2995, let u=u 0 , l=0, F x = 0, F y =0, calculate tool center position x t (u)=-10.7328, y t (u)=26.6064.

[0130] (3) order u pre =u,x t (u pre )=x t (u),y t (u pre )=y t (u), u=u+Δu, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com