pneumatic tire

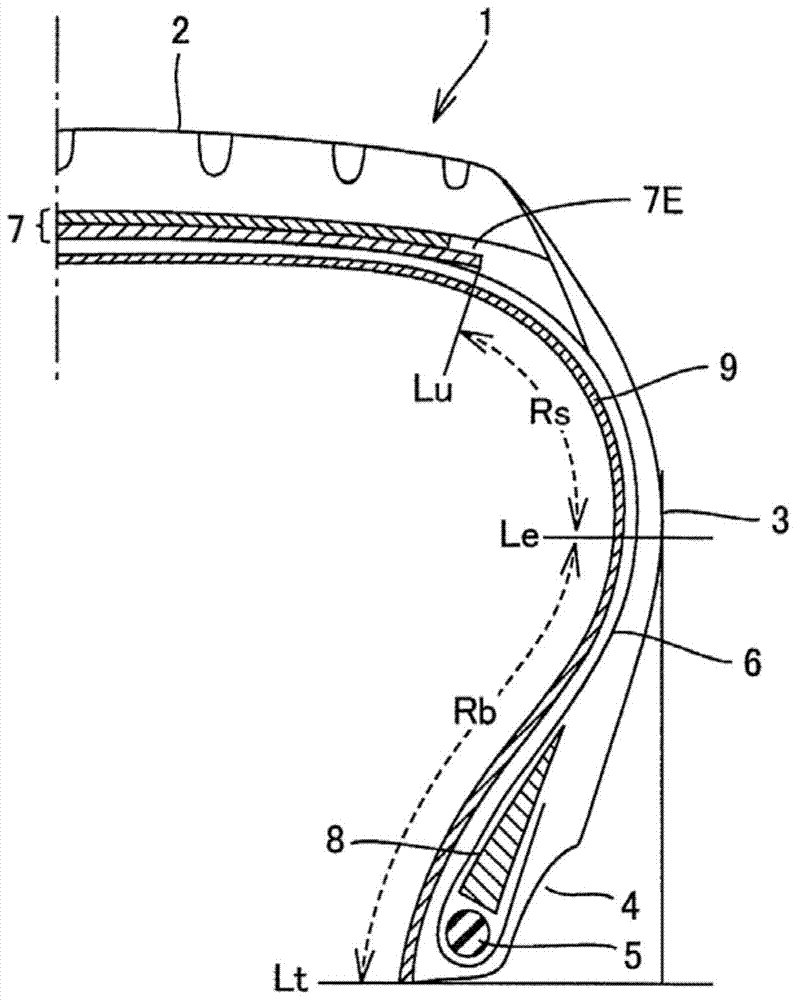

一种充气轮胎、轮胎的技术,应用在充气轮胎、特殊轮胎、轮胎零部件等方向,能够解决橡胶层与防透气层剥离等问题,达到滚动阻力降低、乘坐感觉优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

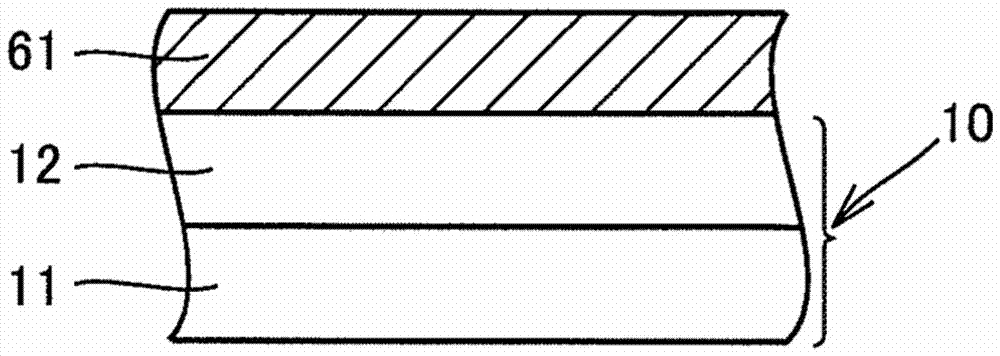

[0077] figure 2 Among them, the lining layer 10 is composed of a first layer 11 and a second layer 12 . The inner liner 10 is provided toward the outer side in the tire radial direction so that the second layer 12 is in contact with the carcass ply 61 . By doing so, the bonding strength between the second layer 12 and the carcass ply 61 can be improved during the vulcanization process of the tire. The polymer laminate can use the polymer composition of the first layer and the polymer composition of the second layer according to figure 2 The sequence shown is obtained by lamination extrusion or co-extrusion equal build-up extrusion.

Embodiment approach 2

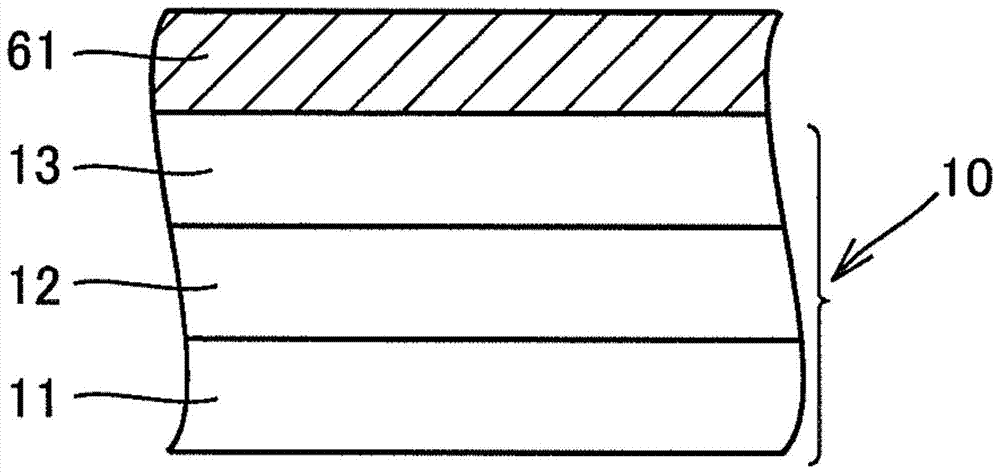

[0079] image 3 Among them, the inner liner 10 is composed of a first layer 11 , a second layer 12 and a rubber sheet layer 13 . The inner liner 10 is provided toward the outer side in the tire radial direction so that the rubber sheet layer 13 is in contact with the carcass ply 61 . Doing so can improve the bonding strength between the rubber sheet layer 13 and the carcass ply 61 during the vulcanization process of the tire.

[0080]

[0081] Pneumatic tires can be manufactured by general manufacturing methods. That is, it can be produced by applying the inner liner 10 to the inner liner of a green tire of the pneumatic tire 1 and vulcanizing and molding it together with other components. When disposing the inner liner 10 on the raw tire, the second layer 12 or the rubber sheet layer 13 of the polymer laminate 10 is disposed toward the outer side in the radial direction of the tire so as to be in contact with the carcass ply 6 . That is, the first layer 11 is disposed to...

Embodiment 1~5、 comparative example 1~7

[0087]

[0088] SIB, SIBS, and SIS used for the first layer and the second layer were prepared as follows.

[0089] (SIB)

[0090] Into a 2 L reaction vessel equipped with a stirrer, 589 mL of methylcyclohexane (dried over molecular sieves), 613 mL of n-butyl chloride (dried over molecular sieves), and 0.550 g of cumyl chloride were added. After cooling the reaction container to -70°C, 0.35 mL of α-picoline (2-picoline) and 179 mL of isobutene were added. Further, 9.4 mL of titanium tetrachloride was added to start polymerization, and the solution was reacted for 2.0 hours while stirring the solution at -70°C. Next, 59 mL of styrene was added to the reaction container, and after continuing the reaction for 60 minutes, a large amount of methanol was added to terminate the reaction. After removing the solvent and the like from the reaction solution, the polymer was dissolved in toluene and washed with water twice. This toluene solution was added to a methanol mixture to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com