Piezo injector

A piezoelectric injector and piezoelectric injection technology, applied in the direction of injection devices, injection devices, fuel injection devices, etc., can solve the problems of restricting the structural freedom of piezoelectric injectors, high manufacturing costs, etc., and achieve pressure loss reduction and reduction Effect of improvement in manufacturing cost and injection amount stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

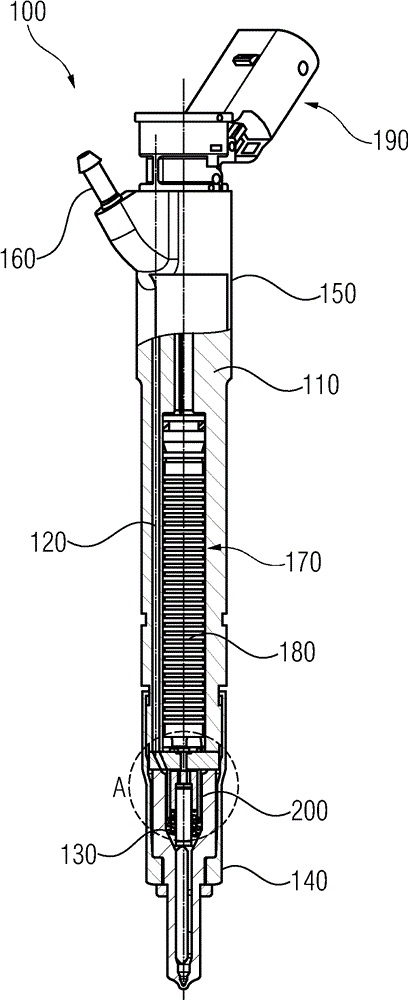

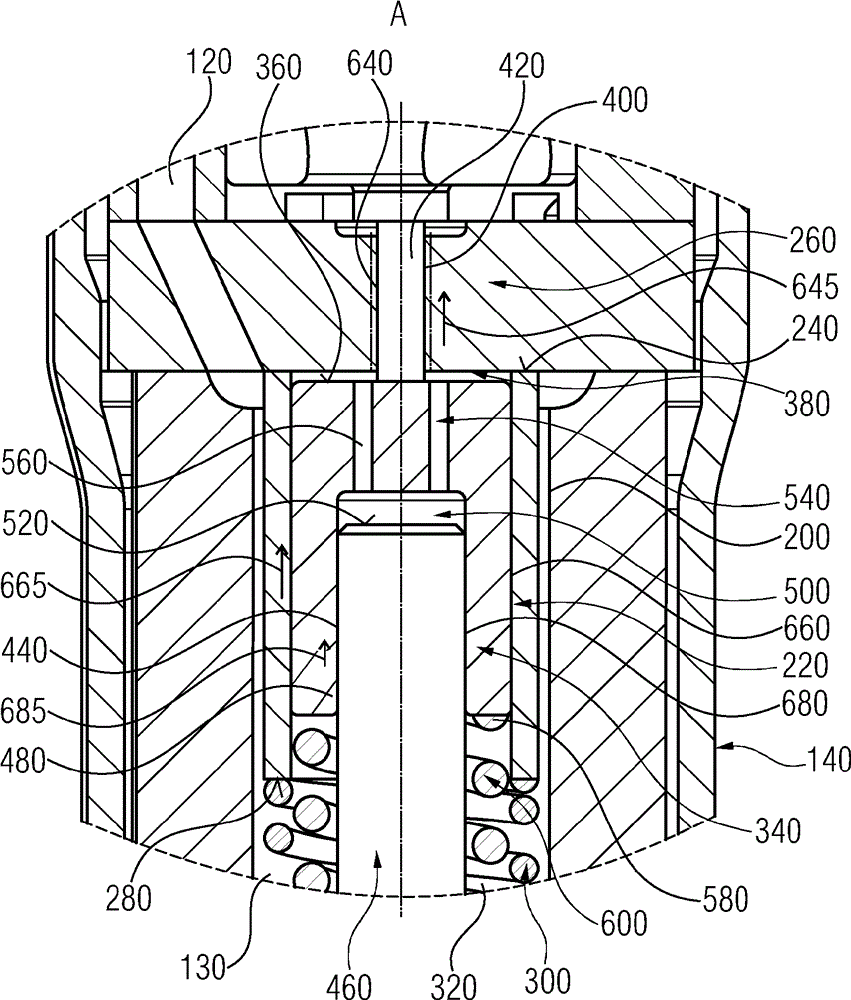

[0018] figure 1 A partial sectional view of a piezoelectric injector according to the invention is shown. Piezo injector 100 may be used to inject fuel into an internal combustion engine. The piezo injector 100 can be used, for example, to inject diesel in a common rail internal combustion engine.

[0019] The piezoelectric injector 100 has an injector housing 110 . The injector housing 110 may be composed of substantially any desired material, since the thermal expansion characteristics of the injector housing 110 are not critical. In particular, injector housing 110 need not be composed of Invar.

[0020] A high-pressure hole 120 is arranged in the injector housing 110 into which highly pressurized fuel can be injected through a high-pressure port. The high-pressure bore 120 extends in the longitudinal direction through the injector housing 110 to a high-pressure region 130 which will be discussed further below in the lower section 140 , namely the nozzle body of the pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com