Tea mashing method of double-pestle tea-mashing machine

A technology of tea pounding machine and pestle, which is applied in the direction of tea processing before extraction, can solve the problems of inconvenient cleaning and low grinding efficiency, and achieve the effects of convenient cleaning, increased grinding efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

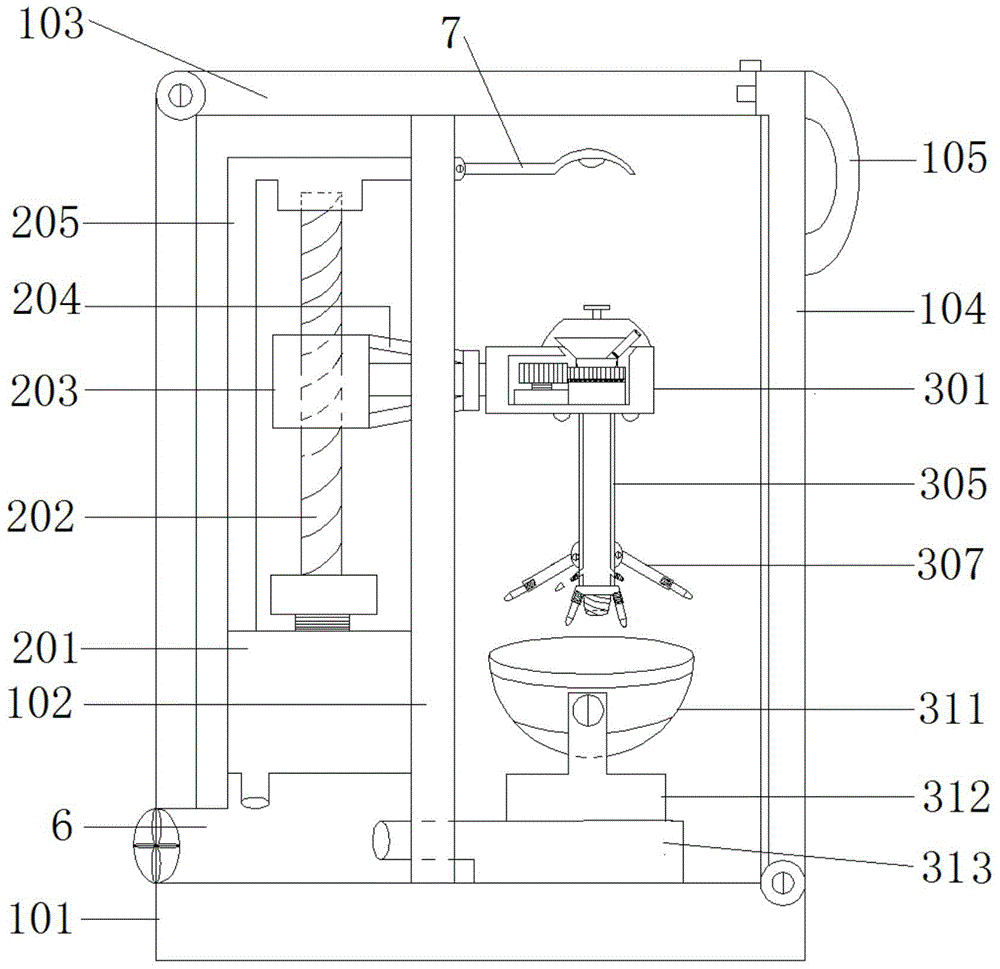

[0054] combine figure 1 , a tea making method for a tea making machine with double pestles in the present embodiment. The tea making machine with double pestles includes a chassis, a lifting mechanism, a stirring mechanism and a feeding mechanism. A lifting mechanism is installed in the cabinet on one side of the 102, and a stirring mechanism and a feeding mechanism are arranged in the cabinet on the other side of the isolation plate 102.

[0055] see figure 1 and figure 2 , the lifting mechanism in this embodiment includes a lifting motor 201, a screw rod 202, a lifting screw sleeve 203, a lifter 204 and a lifter protective shell 205, the lifting motor 201 is installed on the chassis base 101, and the chassis base 101 is also provided with an exhaust fan 6 , there is a partition between the lifting motor 201 and the exhaust fan 6, and there is a cylindrical pipe passing through the partition between the lifting motor 201 and the exhaust fan 6, which can bring the heat gene...

Embodiment 2

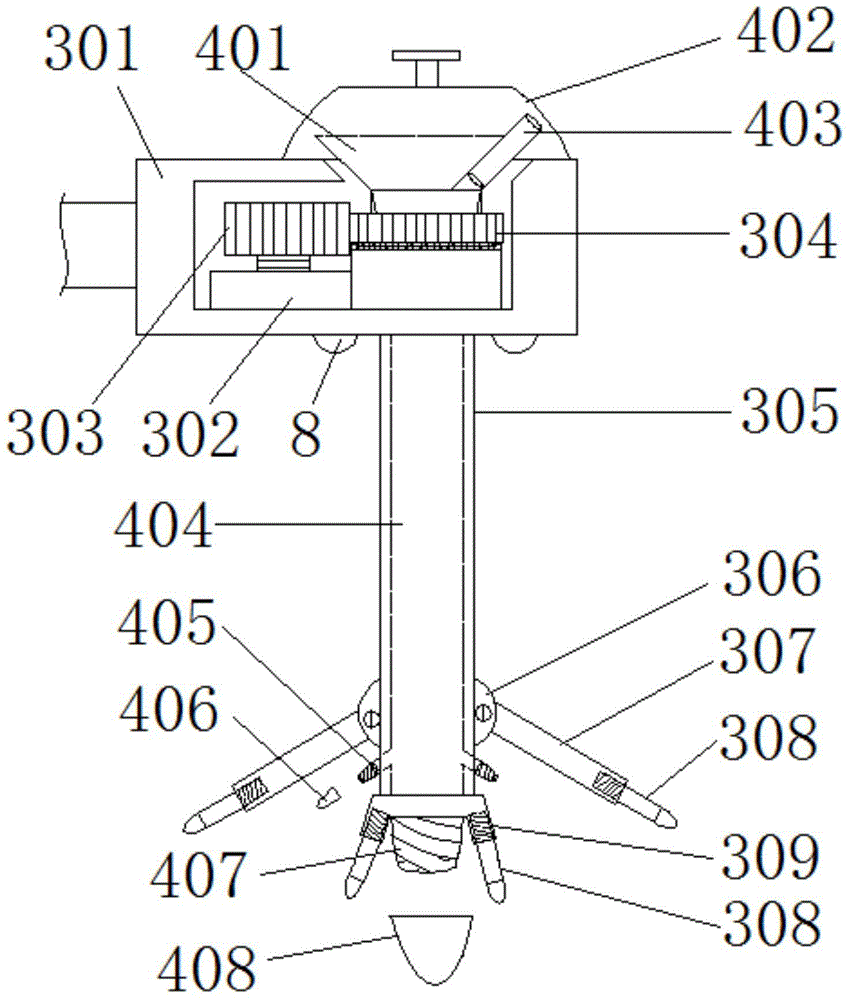

[0071]In this embodiment, a method for making tea with a double-pulsed tea machine, the basic structure of the double-pulsed tea machine is the same as that of Embodiment 1, the difference is that: the feeding funnel 401 in this embodiment is also provided with Feeding pipe 403, the feeding pipe 403 communicates with the feeding chamber 404, not only can add some small spices through the feeding pipe 403, but also connect the feeding pipe 403 with the water delivery pipe during cleaning, so as to quickly deliver water and improve cleaning efficiency.

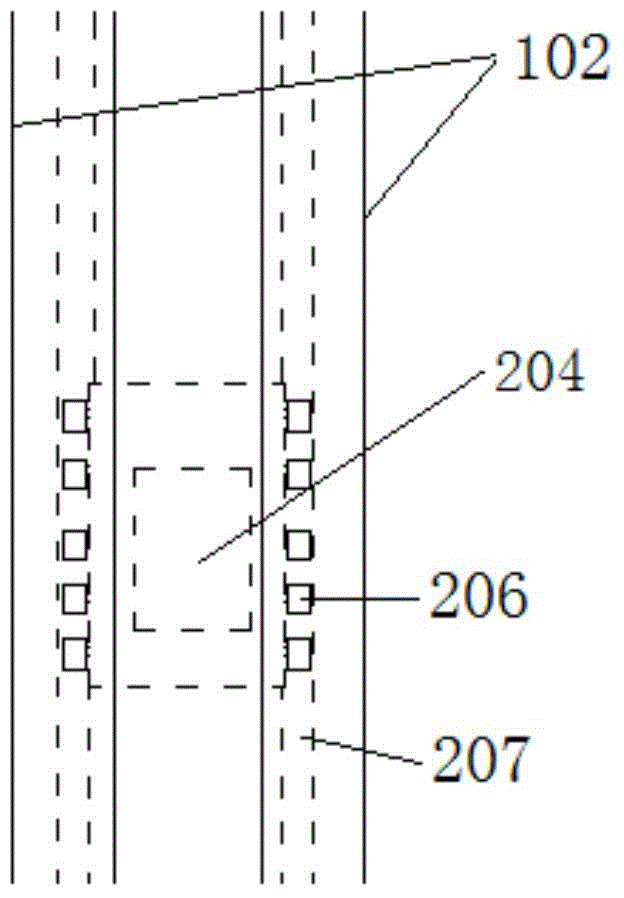

[0072] Roller wheels 206 are arranged on both sides of the lifter 204, and wheel rails 207 are arranged in the said isolation plate 102; friction between.

Embodiment 3

[0074] see figure 1 , a tea making method of a double-pulsed tea machine of the present embodiment, the basic structure of the double-pulsed tea machine is the same as that of Embodiment 2, and the difference is that: the separation plate 102 in this embodiment is equipped with a disinfection Lamp 7, the light pole of this sterilizing lamp 7 is hinged with the isolation plate 102, and the disinfection lamp 7 can be folded close to the isolation plate 102 by the hinge device when not in use, and can start work by the hinge device when it needs to be used. The disinfection lamp 7 can bake and sterilize the cleaned device when it is working, which ensures the sanitation and safety of the Lei Cha products produced.

[0075] see Figure 6 , the engaging mechanism in this embodiment includes an opening and closing button 501, a lever 502, a transverse spring 503, a buckle 504, and a longitudinal spring 505; 502, the other end of the lever 502 is pressed by the longitudinal spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com