Precoated type magnetic lining plate

A magnetic lining and pre-coating technology, which is applied in the fields of mining, metallurgy, electric power, building materials, and ports. Pollution, improved adaptability, and the effects of expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

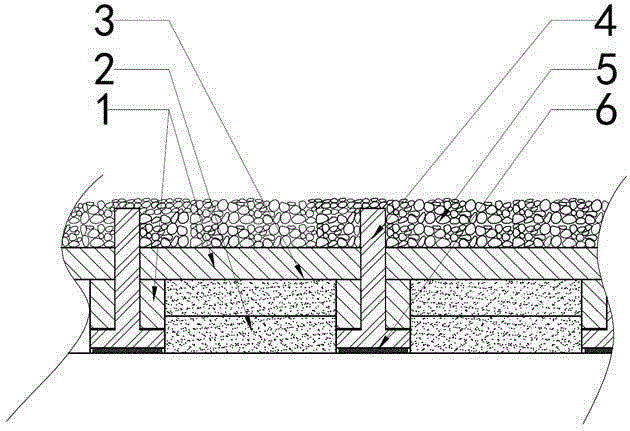

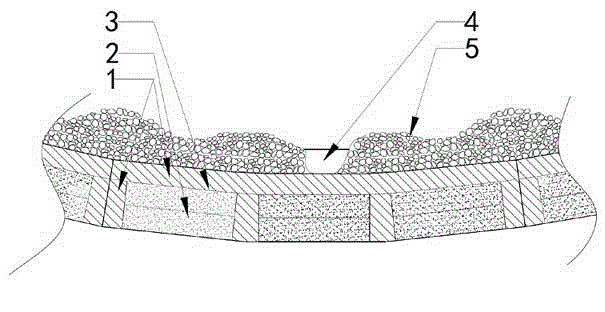

[0020] like figure 1 and figure 2 As shown, the welded magnet protector 1 is bonded to the magnet group 2 inside by the adhesive 3, and the pre-clad protector 4 is matched with the magnet protector 1 through the protrusion on the pre-clad protector 4 , the pre-coating layer 5 is adsorbed on the working surface of the magnetic backing plate, and the buffer body 6 is bonded to the pre-coating layer protective body 4 through the adhesive 3 .

[0021] in:

[0022] Magnet group 2 is a permanent magnet, using ferrite permanent magnet material; the outer surface of the magnet group is adsorbed on the inner surface of the ball mill barrel (end), along the circumferential direction of the ball mill barrel (end), two adjacent magnet groups are N poles , S poles are arranged alternately; the magnet group 2 is fixedly connected with the magnet protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com