Adjustable entrance continuous flat pressing heat press machine

An adjustable, hot press technology, applied in the direction of presses, veneer presses, plywood presses, etc., can solve the problems of unsatisfactory profile of the entry end of the press, high failure rate, and complex system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

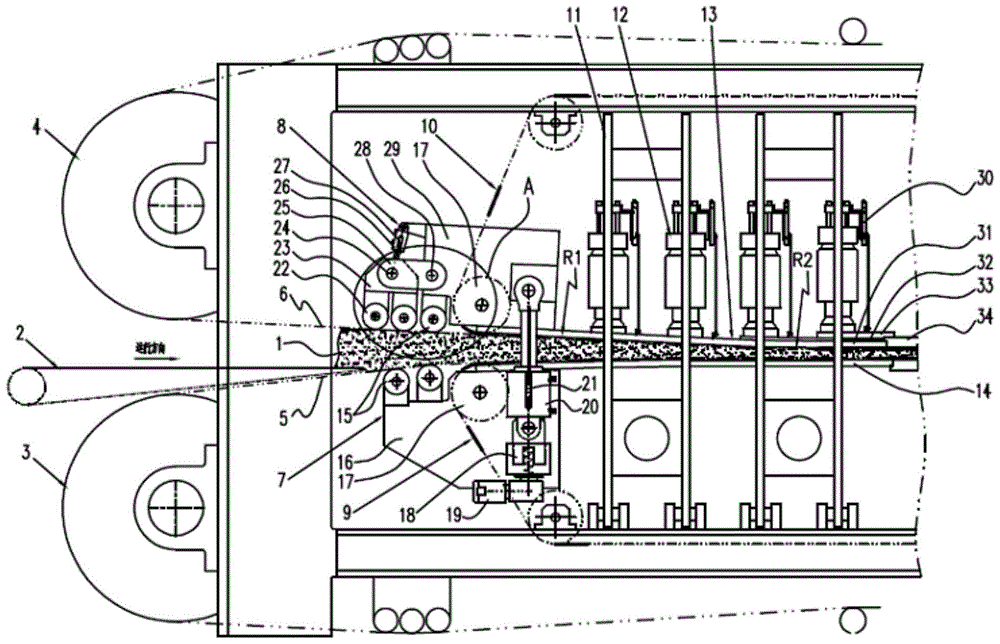

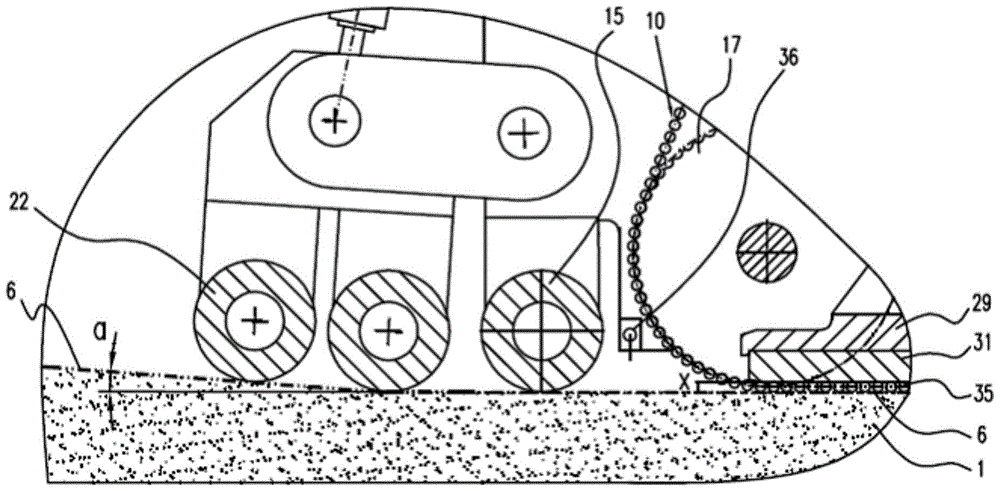

[0028] See attached below Figure 1-2 Specific embodiments of the present invention are described.

[0029] as attached figure 1 As shown, the inlet adjustable continuous flat pressing hot press of the present invention comprises: an upper feed assembly 8, a lower feed assembly 7, an upper entry hot pressing plate 13, and a lower entry hot pressing plate 14, wherein the upper entry hot pressing plate 13 and The upper feed seat 29 of the upper feed assembly 8 is fixedly connected, the lower feed plate 14 is fixedly connected with the lower feed seat 16 of the lower feed assembly 7, and the upper feed plate 13 and the lower feed plate 14 together define the press Enter the profile of the end. In the present invention, the adjusting mechanism for adjusting the size of the inlet at the inlet end of the press is configured as a screw adjusting mechanism for driving the upper feed seat 29 and the lower feed seat 16 to move relatively. Compared with the servo oil cylinder adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com