Production method of 3D curved lens

A manufacturing method and curved surface technology, which can be applied to other household appliances, optical components, household appliances, etc., can solve the large number of CNC engraving machines, the lack of forming 3D curved plastic lenses, and the low yield rate of 3D forming glass processing and other problems to achieve the effect of small deformation, low cost and high product hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

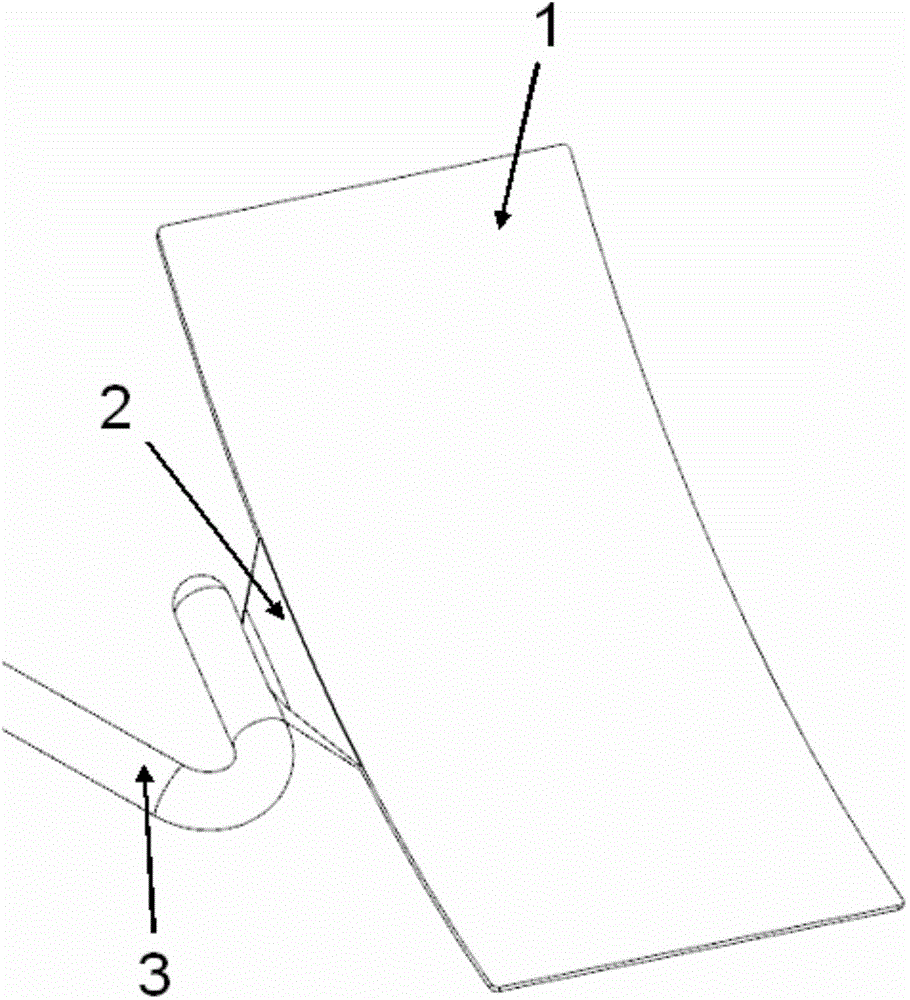

[0034] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

[0035] In some embodiments, the method for manufacturing a 3D curved lens includes the following steps:

[0036] (1) Injection molding step: the molten material is injected from one side of the mold cavity, and when the molten material fills 10% to 40% of the volume of the mold cavity, an auxiliary gas is injected into the mold cavity;

[0037] (2) Compression step: when the molten material fills 45% to 90% of the volume of the mold cavity, the auxiliary gas is discharged, and the inside of the mold cavity starts to be compressed to obtain the 3D curved lens.

[0038] In a preferred embodiment, including:

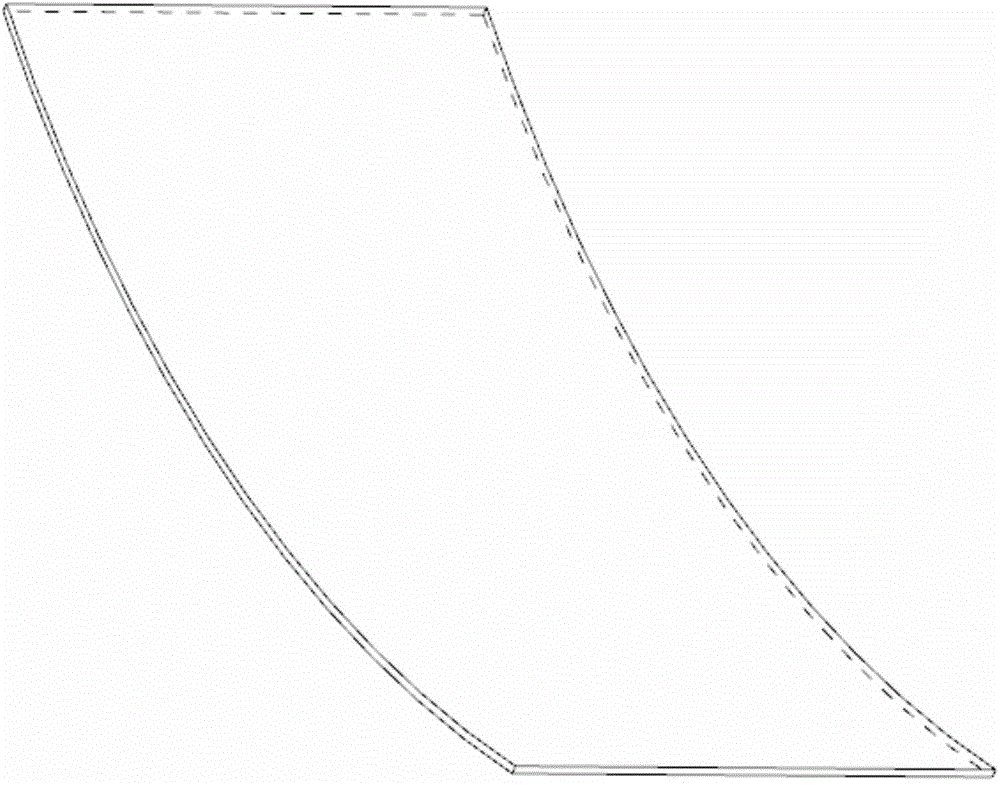

[0039] like figure 2 As shown, the shape of the molded 3D curved lens is a rectangular arc surface, and the melting material used is PC. The final molded 3D curved lens is transparent, and the thickness can reach 0.60 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com