Plastic product fusion joining process and fusion joining device thereof

A technology of plastic products and welding, applied in the field of plastics, can solve the problems of high manufacturing cost, high production cost and lack of market competitiveness of injection molding equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

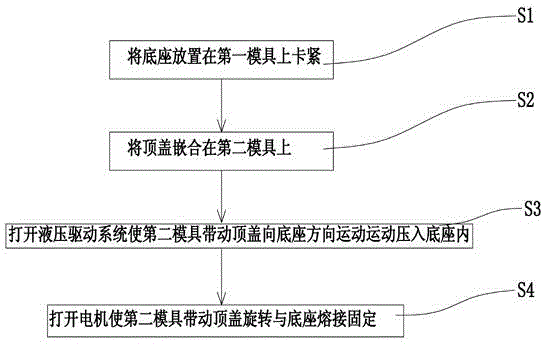

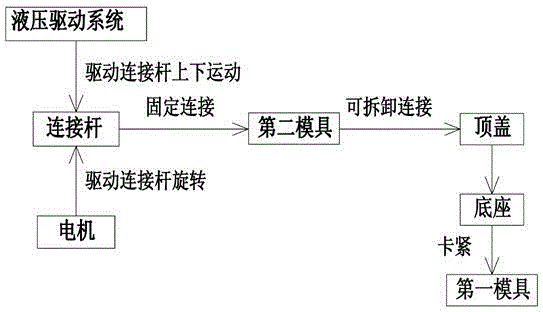

[0026] Embodiment 1: as Figure 1 to Figure 3 As shown, the technical scheme adopted by the present invention is as follows: a welding process for plastic products, comprising the following steps:

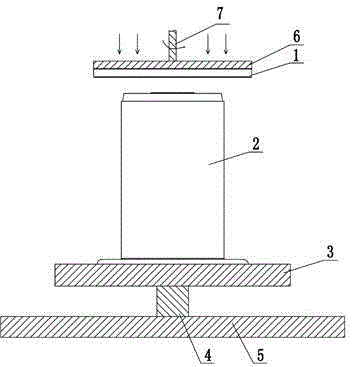

[0027] S1. Place the base 2 on the first mold 3 and clamp it tightly;

[0028] S2. Embedding the top cover 1 on the second mold 6, so that the base 2 and the top cover 1 are arranged opposite to each other;

[0029] S3. Turn on the hydraulic drive system to make the second mold 6 drive the top cover 1 to move towards the base 2, and press it into the base 2;

[0030] S4. Turn on the motor to make the second mold 6 drive the top cover 1 to rotate relative to the base, so that the top cover 1 and the base 1 are welded and fixed.

[0031] The base 2 in step S1 includes a supporting base 23, a base body 24, a first welding ring surface 21 and a first rib 22, wherein the supporting base 23 is a plate-like structure, and the base body 24 is fixedly arranged on the supporting ba...

Embodiment 2

[0037] Embodiment 2: as Figure 4 to Figure 6 As shown, it is the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that first ribs are arranged at intervals on the first welding ring surface and the second welding ring surface of Embodiment 1 respectively. 22 and the second rib 13, the first rib 22 and the second rib 13 are strip-shaped structures, and their material is consistent with the material of the top cover and the base, and is integrally injection molded with the top cover and the base, the first rib 22 and the second ribs 13 are arranged at even intervals along the periphery of the first welding ring surface and the second welding ring surface respectively. When welding, the top cover is pressed into the base, and the first ribs and the second ribs are alternately arranged. Two adjacent first ribs 22 and second ribs 13 are engaged with each other. When the motor drives the top cover to rotate, the first ribs 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com