Methanation method and device for preparation of synthetic natural gas

A synthetic natural gas and methanation technology, applied in the field of chemical engineering, can solve the problems of long process flow, many equipment, high energy consumption, etc., and achieve the effects of streamlining the process, improving energy efficiency and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 4The shown basic methanation device for producing synthetic natural gas includes a first-stage methanation reactor 1, a circulation compressor 2, a second-stage methanation reactor 3, a water cooler 11, and a first water separator 6 connected in sequence. The first-stage methanation reactor 1 is externally connected with a steam drum 4 to by-produce steam, the first-stage methanation reactor 1 is a coiled tube heat exchange reactor, and the second-stage methanation reactor 3 is an adiabatic reactor.

[0044] In this embodiment, the synthesis pressure of the first-stage methanation is 3-6 MPa, the synthesis pressure of the second-stage methanation is 10 MPa, and the pressure of the second-stage methanation reactor 3 is higher than that of the first-stage methanation reactor 1 .

[0045] When the above-mentioned device is in operation, the purified feed gas is first subjected to the pressure of coal gasification and purification pressure level (for example,...

Embodiment 2

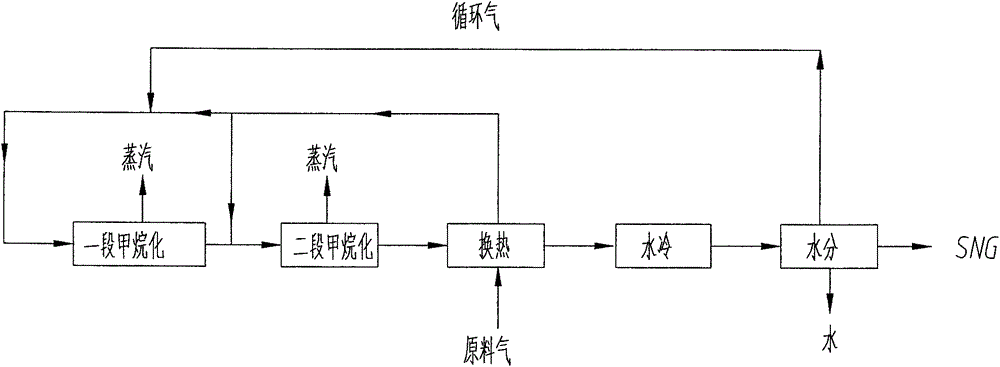

[0047] Such as Figure 5 The shown methanation device for producing synthetic natural gas includes a first-stage methanation reactor 1, a second-stage methanation reactor 3, a first heat exchanger 8, a second heat exchanger 9, a water cooler 11, and a cycler 13 And the first water separator 6, the one-stage methanation reactor 1, the second-stage methanation reactor 3, the first heat exchanger 8, the second heat exchanger 9, the water cooler 11, the first water separator 6 , the circulator 13 are connected in sequence, and the outlet of the circulator 13 is connected with the second heat exchanger 9 and the inlet of the first-stage methanation reactor 1 in sequence.

[0048] When the above-mentioned device is in operation, the purified raw material gas is heated to 250-300°C through the first heat exchanger 8 and the reaction gas, and then the raw material gas is divided into two streams, and one raw material gas enters the first-stage methanation reactor 1. React at 400°C, t...

Embodiment 3

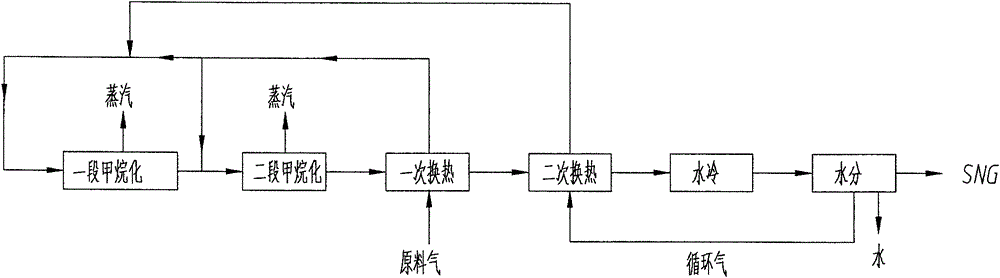

[0049] Such as Figure 6 The shown device, the device comprises a purifier 5, a first-stage methanation reactor 1, a second-stage methanation reactor 3, a first heat exchanger 8, a second heat exchanger 9, a third heat exchanger 10, The water cooler 11, the first water separator 6, the second water separator 7, the steam generator 14, the first section of the methanation reactor 1, the first heat exchanger 8, the first water separator 6, and the circulation section and the circulation compressor 2, the second heat exchanger 9, and the second-stage methanation reactor 3 composed of the compression section, and the outlet of the second-stage methanation reactor 3 exchanges heat with the second heat exchanger 9 and the third Device 10, water cooler 11, and the second water separator 7 are connected sequentially, wherein the outlet pipeline of the compression section of the circulating compressor 2 is connected with the second heat exchanger 9, and then connected with the inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com