Multi-pulse injection control method of high-pressure common-ail diesel engine injector

A diesel engine and engine controller technology, applied in engine control, fuel injection control, machine/engine, etc., can solve problems such as occupying system interrupt resources, affecting system real-time performance, and excessive, to achieve the best control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

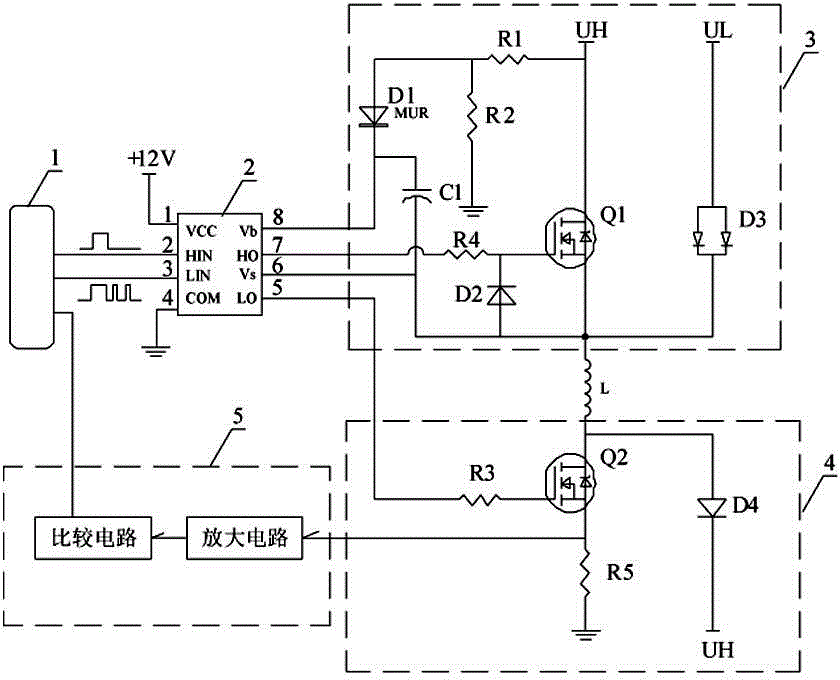

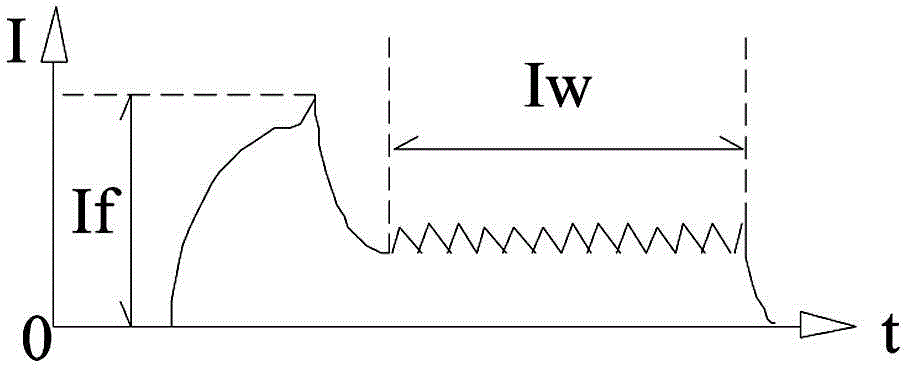

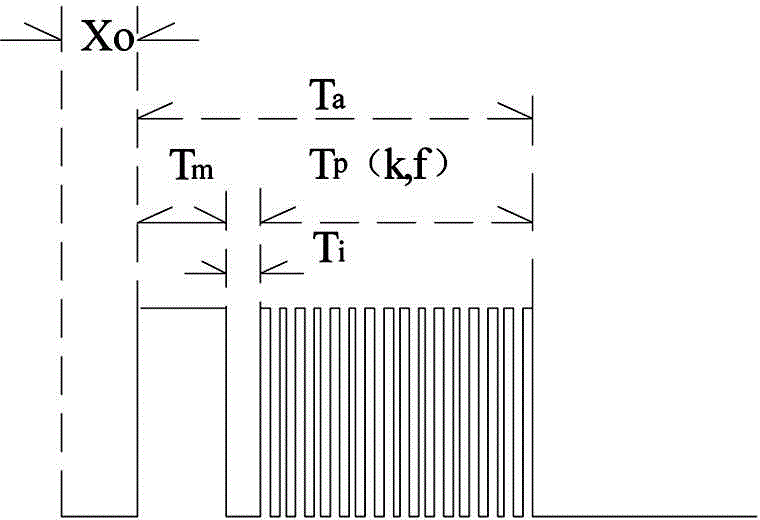

[0012] In the multi-pulse injection control method of a high-pressure common rail diesel engine injector according to the present invention, the engine controller host adopts a CPU (such as MCF5235 or MPC5634) containing an eTPU (enhanced timing processing unit) module of Freescale Company through a structure Array sends multipulse parameters to figure 1 In the parameter memory of microcontroller 1 (microcontroller 1 is MCF5233; eTPU is embedded inside; eTPU is a programmable I / O port controller with its own processor core and separate memory.) In the parameter memory of microcontroller 1, according to The structure array sent by the engine controller host CPU is directly generated as image 3 Optimized waveform including main pulse width, zero pulse width and hold wave is shown ( image 3 Among them, Tm is the main pulse width; Ti is the zero pulse width, that is, the interval time between the main pulse and the PWM holding wave; Tp is the duration of the PWM holding wave; k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com