Rodless hydraulic transmission oil pumping system

A hydraulic transmission and oil pumping technology, applied in the field of petroleum development and exploration, can solve the problems of complex structure, unsatisfactory cost and efficiency, and large maintenance workload of hydraulic piston pump, and achieve a simple structure, wide application range and low loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

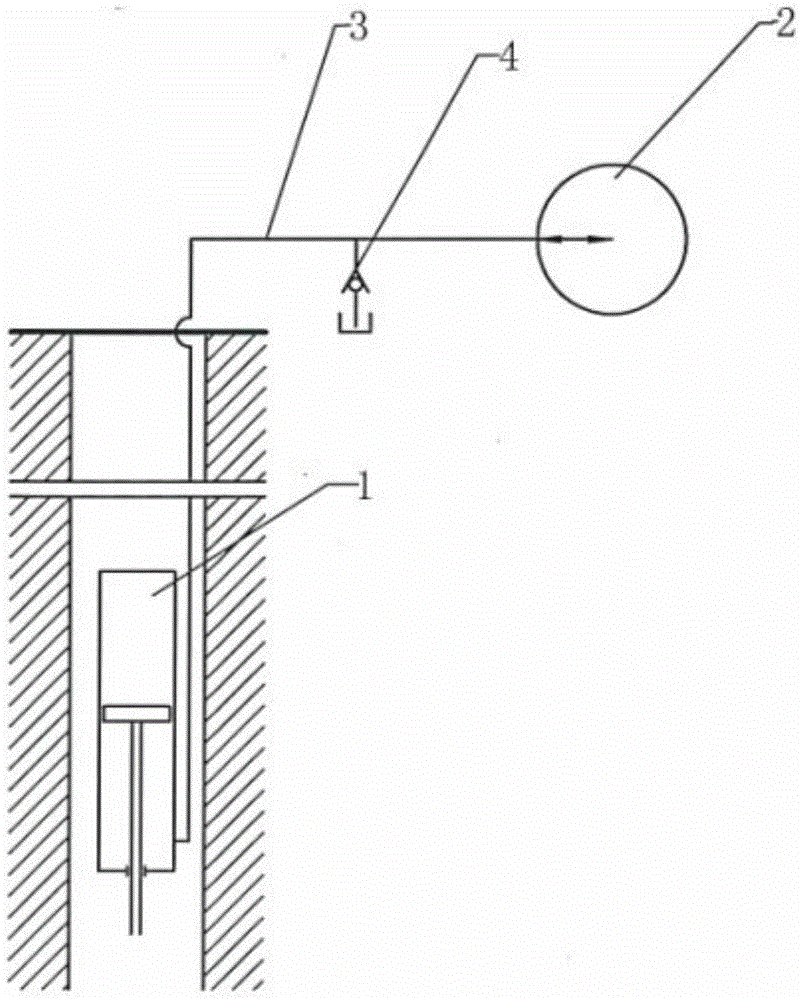

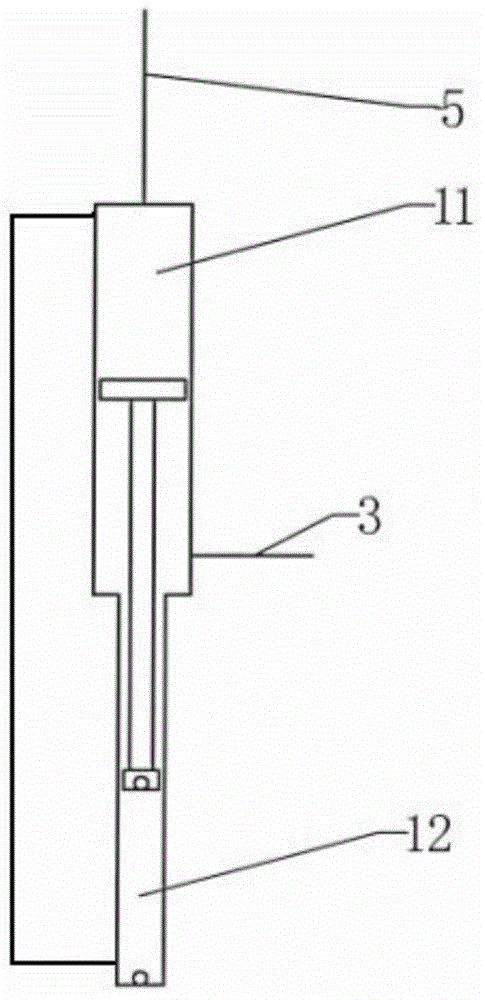

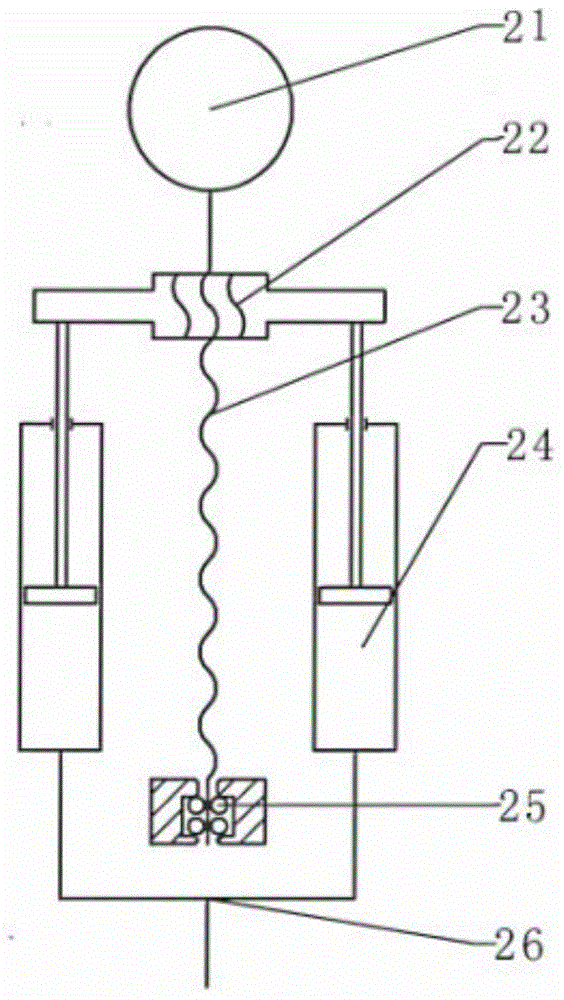

[0029] see Figure 1 to Figure 6 , shows the rodless hydraulic transmission pumping system of the present invention.

[0030] see figure 1 , simply shows the basic structure of the whole rodless hydraulic transmission oil pumping system of the present invention. A brand-new hydraulic transmission oil production method is introduced, which mainly replaces the sucker rod in the prior art through hydraulic pipelines, and uses the up and down reciprocating flow of liquid to transmit the reciprocating motion to the underground.

[0031] In order to realize the hydraulic transmission of the present invention, the rodless hydraulic transmission oil pumping system includes a hydraulic cylinder 1 and a hydraulic pump 2, and the hydraulic cylinder 1 is arranged between the tail pipe 9 in the oil extraction string and the production oil pipe 5 that supplies oil to the outside of the well, The hydraulic pump 2 is connected to the hydraulic cylinder 1 through a hydraulic pipeline 3 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com