Magnetic-flux-gate current sensor

A current sensor, fluxgate technology, applied in voltage/current isolation, measuring current/voltage, instruments, etc., can solve problems such as poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

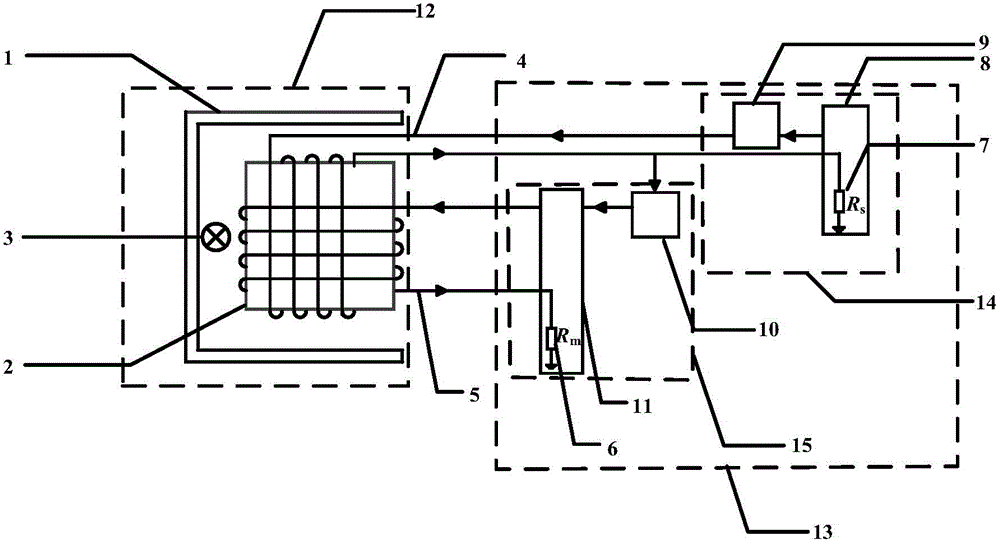

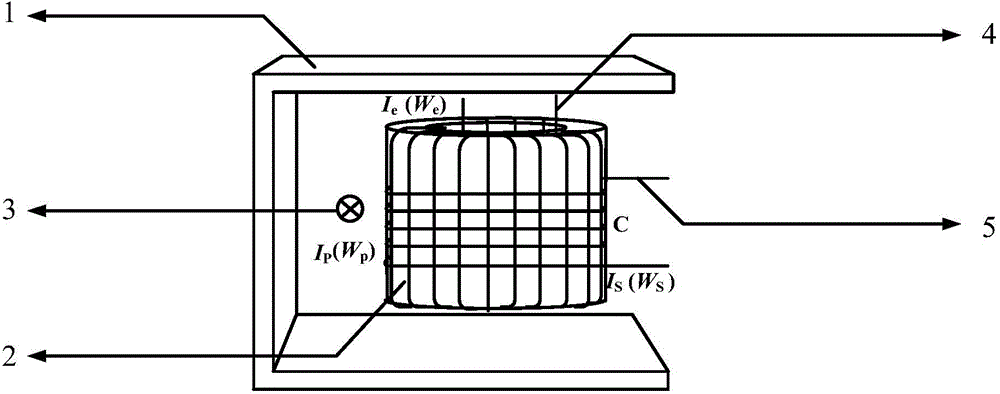

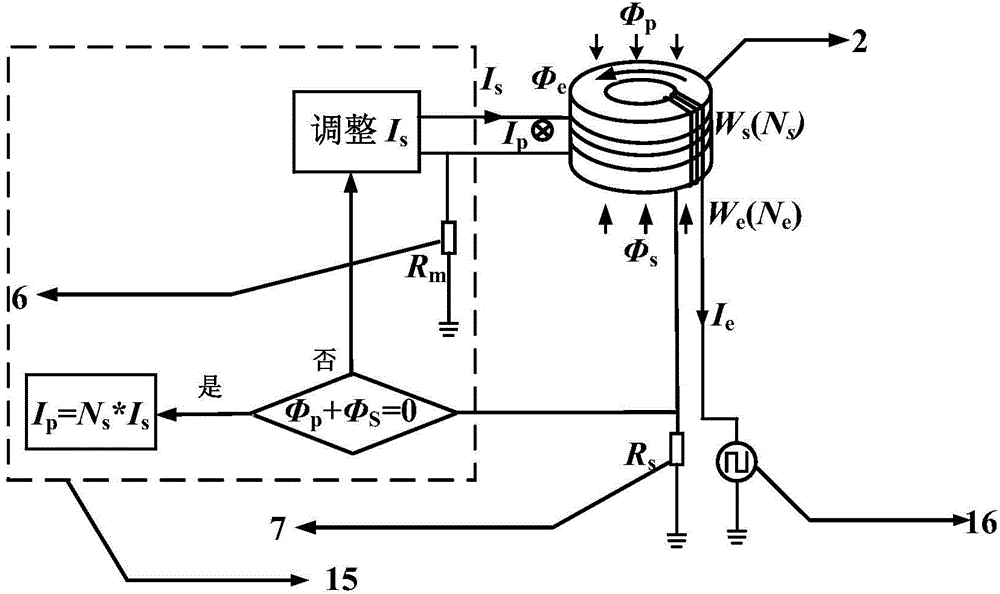

[0050] according to figure 1 , figure 2 , Figure 4 and Figure 5 The illustrated embodiment constitutes the fluxgate current sensor of this embodiment, which is a fluxgate current sensor with a magnetization shell 1 and windings distributed orthogonally, including a fluxgate detection probe 12 and a signal processing circuit 13; Among them, the fluxgate detection probe 12 is composed of a magnetic gathering shell 1 plus a ring magnetic core 2 and an exciting winding 4 plus a secondary feedback winding 5. The ring magnetic core 2 is placed inside the magnetic gathering shell 1, and the exciting winding 4 is a wire. The winding formed on the annular magnetic core 2 is uniformly wound along the radial direction of the annular magnetic core 2, and the secondary feedback winding 5 is a winding formed by winding uniformly along the circumferential direction of the annular magnetic core 2 after the excitation winding 4 is wound. Signal processing circuit 13 is divided into excit...

Embodiment 2

[0052] Except that the excitation winding 4 is a winding formed by uniformly winding 125 turns of a wire on the annular magnetic core 2 along the radial direction of the annular magnetic core 2, the secondary feedback winding 5 is formed along the annular magnetic core after the excitation winding is wound. Except for the winding formed by uniform winding of 225 turns in the circumferential direction, the others are the same as in Embodiment 1.

Embodiment 3

[0054] Except that the excitation winding 4 is a winding formed by uniformly winding 150 turns of a wire on the annular magnetic core 2 along the radial direction of the annular magnetic core 2, the secondary feedback winding 5 is formed along the annular magnetic core after the excitation winding is wound. Except for the winding formed by uniform winding of 250 turns in the circumferential direction, the others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com