Alternate current/direct current voltage transducer and detection method

A technology of AC and DC voltage and detection method, which is applied in the direction of measurement using digital measurement technology, can solve the problems of affecting measurement accuracy, complex calculation, complex structure of voltage sensor, etc., and achieve simple processing method, stable and reliable device, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

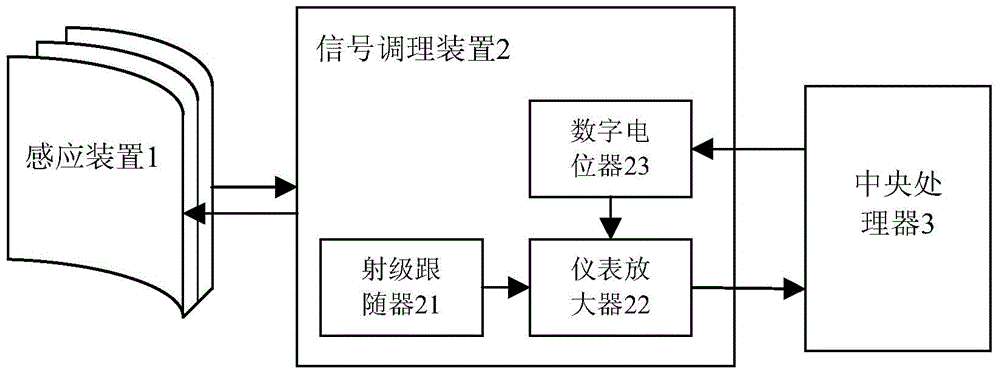

[0066] This embodiment provides an AC and DC voltage sensor, the specific structural block diagram is as follows figure 1 As shown, it includes: induction device 1 , signal conditioning device 2 and central amplifier 3 .

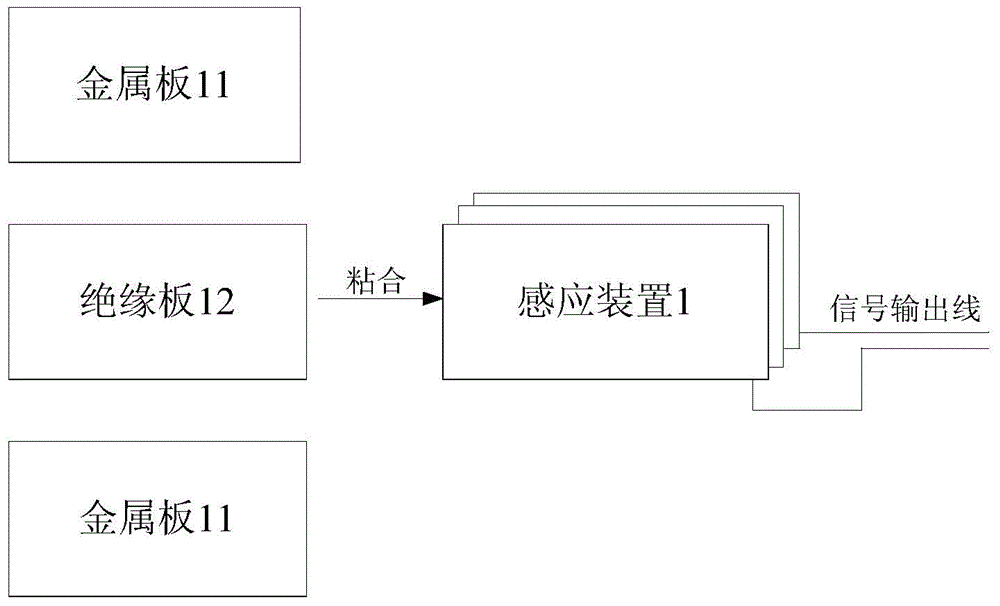

[0067] First, the sensing device 1 is as image 3 As shown, the induction device 1 is an overlapping three-layer structure, bonded together, including two metal plates 11 on both sides and an insulating plate 12 between the two metal plates 11, the induction device 1 It is not in contact with the component under test 14 and is arranged along the extending direction of the component under test 14 . In this embodiment, it is used to measure the power supply line voltage of 10kV, including a shown induction device 1, as shown in Fig. 11 is a copper plate with a thickness of 0.1 millimeter, a length of 20 centimeters, a width of 10 centimeters, and a surface area of 200 square centimeters. The thickness of the insulating plate 12 is 3 millimeters, and the si...

Embodiment 2

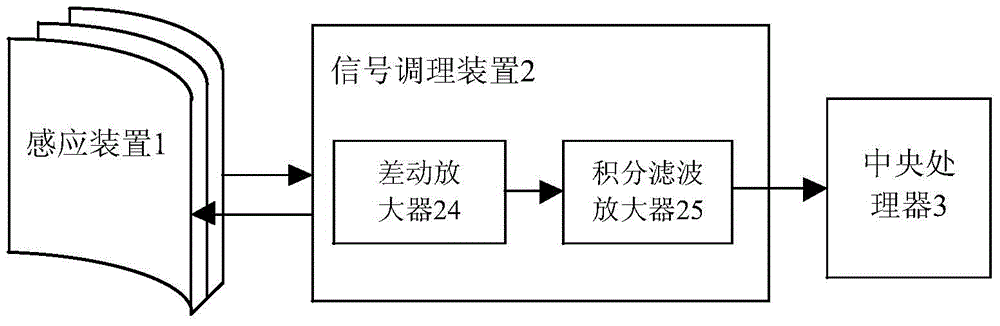

[0077] In this embodiment, on the basis of the first embodiment, the signal conditioning device 2 is different from the first embodiment, as figure 2 As shown, it specifically includes: a differential amplifier 24 and an integral filter amplifier 25 . The differential amplifier 24 is connected to the two metal plates 11 of the induction device 1 respectively, and amplifies and outputs the voltage signal induced by the induction device 1; the integral filter amplifier 25 is connected to the differential amplifier 24 to convert the differential The voltage signal output by the dynamic amplifier 24 is output after being filtered and denoised. It can perform multi-stage filtering and multiple amplification processing, so that the obtained voltage signal is stable and reliable.

Embodiment 3

[0079] The difference between this embodiment and Embodiment 1 is that the sensing device 1 is a curved surface, and its structural schematic diagram is as follows Figure 4 As shown, that is, the induction device 1 is a semicircular curved surface, which is arranged around the element to be tested, and is mainly used for voltage measurement of cylindrical wires. The schematic diagram of its installation is shown in Figure 7 shown.

[0080] The surface area of the metal plate 11 and the insulating plate 12 is 5-1000 square centimeters, and the thickness of the metal plate is 0.01-10 mm. The thickness of the insulating board is 0.1-100 mm. The distance between the sensing device and the component to be tested is 0.1-1000 mm. The surface area and thickness of the metal plate 11 and insulating plate 12 and the distance from the component to be tested are selected mainly according to the comprehensive factors of the voltage level of the component to be tested 14, ambient envi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com