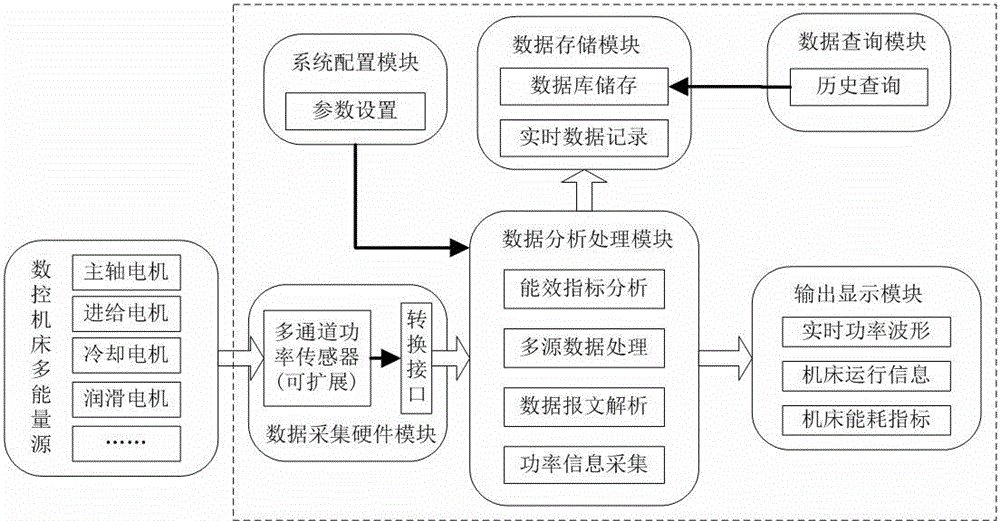

Multi-information online detection system for machine tool multi-source energy consumption system

A detection system, machine tool technology, applied in general control systems, control/regulation systems, computer control, etc., can solve the problem of lack of multi-source energy consumption system multi-information online detection system for machine tools, inability to obtain effective energy of multi-energy source machine tools, instantaneous State efficiency, energy utilization, key parameters of energy efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

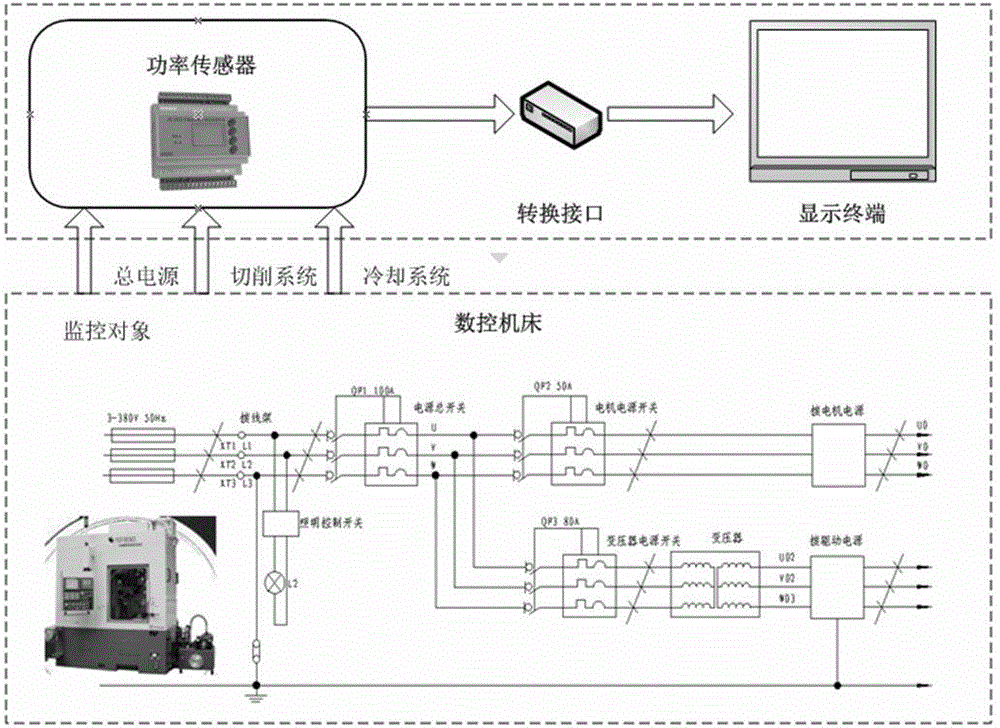

Method used

Image

Examples

Embodiment

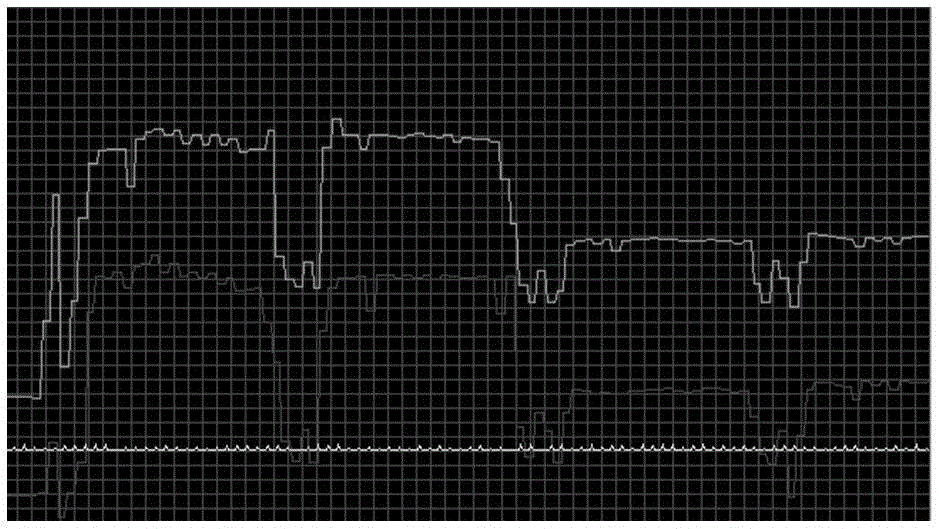

[0074] The machine tool to be tested is the PL700 machining center of Chengdu Prius Machine Tool Co., Ltd., and the following is an example of milling a certain box plane on the PL700 machining center. The method and system of the present invention are used for detection. The process is as follows:

[0075] Step 1. Analyze the energy sources of the PL700 machining center. Each independent machine tool energy consumption component has a corresponding energy consumption source. The main energy sources of the PL700 machining center are shown in Table 1.

[0076] Table 1 Energy source of PL700 machining center

[0077] parts

cutting system

Spindle frequency conversion motor and 3 feed axis motors

[0078] Tool magazine system

Tool magazine motor

cooling system

cooling pump motor

Main electric control box air conditioner

[0079] Among them, the tool magazine system and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com