Pulse laser synchronous riveting and welding method and device for ultra-thin plates

A pulsed laser and plate technology, applied in the field of manufacturing, can solve the problems of further improvement of connection strength, incomplete sealing, residual tensile stress, etc., to achieve the effect of environmental friendliness, low openness requirements, and improved forming limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

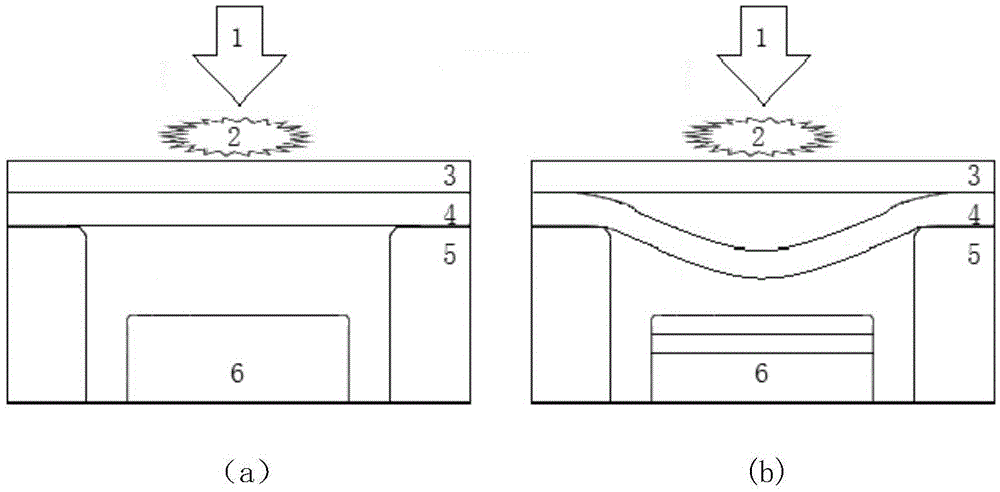

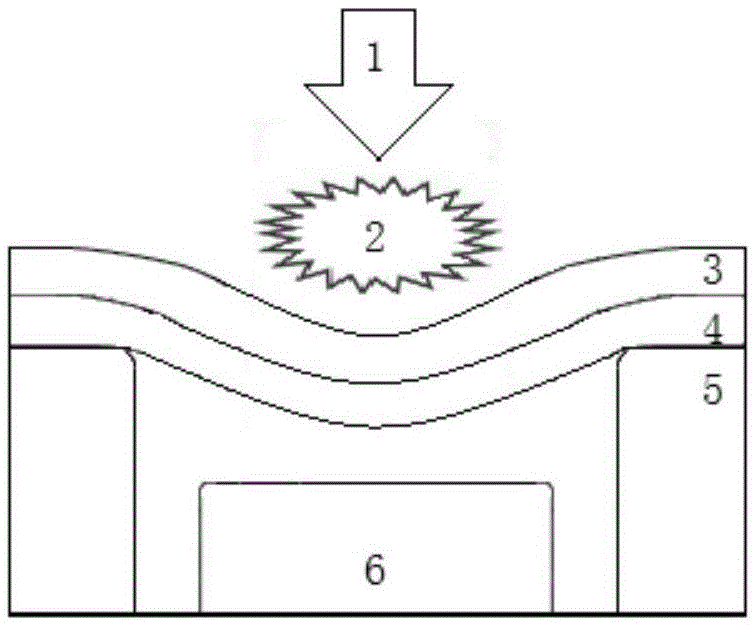

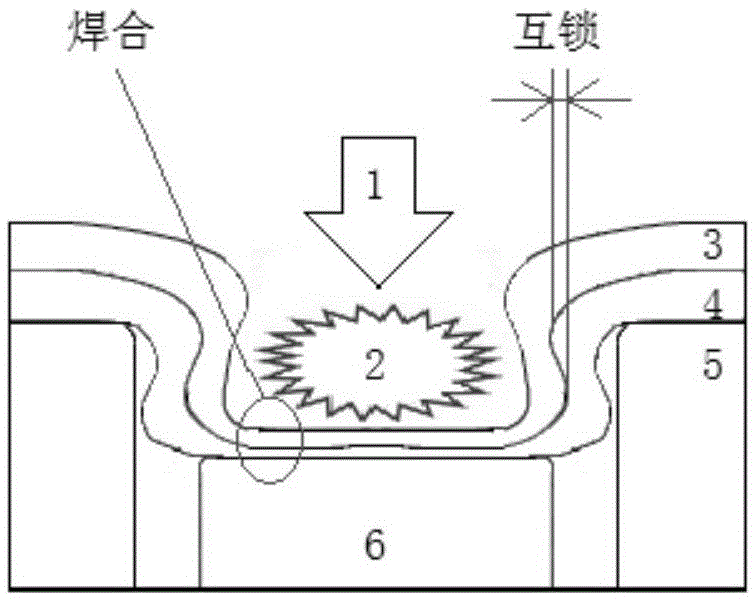

[0024] Ultra-thin plate pulse laser synchronous riveting and welding method: stack the upper and lower plates and place them on the die 5 with die holes. The die 5 is equipped with a bottom die 6, and the upper surface of the upper plate 3 is coated or The energy absorbing layer is not applied, and the pulsed laser beam 1 is used to act on the upper plate 3 or the energy absorbing layer coated on the surface of the upper plate 3 to form an explosive plasma 2, and the upper plate 3 then hits the lower plate 4, and the upper plate 3 and the lower plate 4. High strain rate plastic flow coupling is generated. Under the constraint of the bottom mold, the upper plate 3 and the lower plate 4 are jointly plastically formed into a riveted buckle shape, thereby generating mechanical interlocking and riveting. During the plastic deformation process, compressive stress exists on the contact interface between the upper plate 3 and the lower plate 4, and high-speed sliding and shear deformat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com