Forming technology for cup body parts

A forming process and parts technology, which is applied in the forming process of cup parts, can solve the problems of uneven material thickness variation of parts, failure to ensure qualified delivery of parts, and poor surface quality of parts, so as to improve surface quality and reduce product scrapping efficiency, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A forming process of a cup body part, comprising the following steps:

[0026] (1) Cutting

[0027] CNC machine tools are used for milling and blanking, and the blanking size is Ф85;

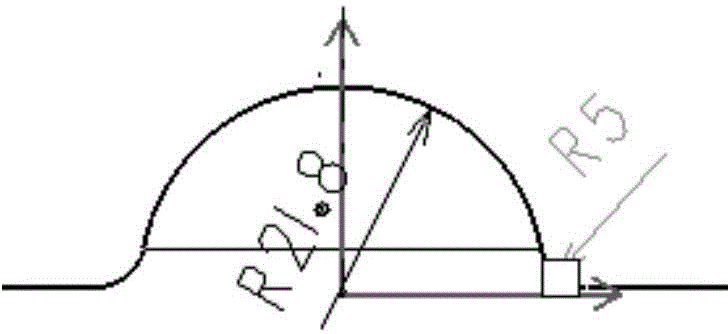

[0028] (2) Hemisphere deep drawing with flange

[0029] 100T punching machine is used for the first deep drawing, and the part is processed into a hemispherical shape with a flange edge;

[0030] (3) Intermediate annealing

[0031] Eliminate internal stress during part forming;

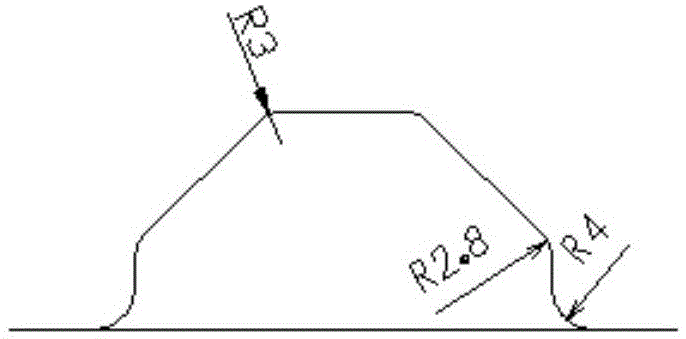

[0032] (4) Transition deep drawing

[0033] 100T punch press is used for the second deep drawing;

[0034] (5) Final deep drawing

[0035] Use 100T punch press for the third deep drawing;

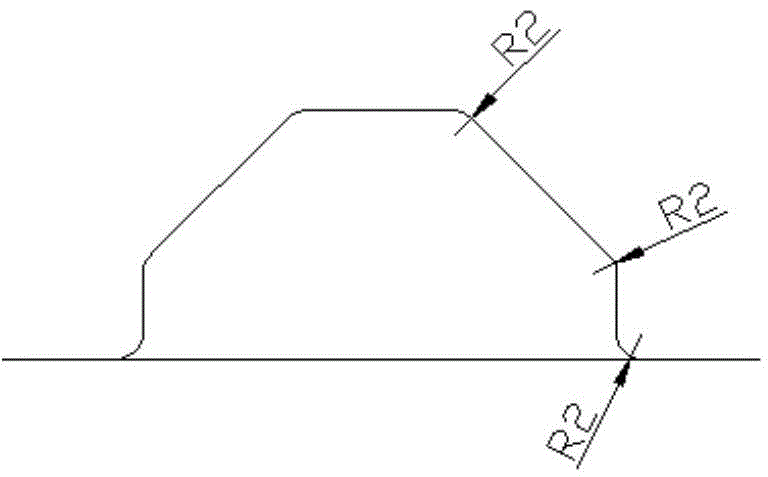

[0036] (6) Die-cut trimming

[0037] Trimming is carried out with a trimming die and a rubber bladder hydroforming machine;

[0038] (7) Hole making and shape correction

[0039] Hole making and shape correction are carried out using molds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com