Three-dimensional printing manufacturing method of artificial jade

A kind of artificial jade, three-dimensional technology, applied in the direction of manufacturing tools, ceramic molding machines, additive processing, etc., can solve the problems of high labor intensity of operators, low precision of artificial jade, large fixed investment, etc., to achieve high practicality and Promote application value, high hardness, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

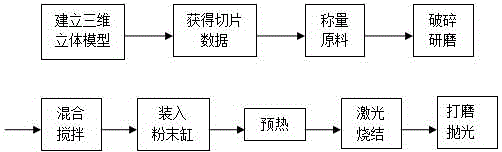

[0029] Example 1: Press figure 1 As shown, the raw materials and proportions of artificial jade production:

[0030] PbO: 6%

[0031] al 2 o 3 : 75%

[0032] Cr 2 o 3 : 5%

[0033] SiO 2 : 14%.

[0034] The preparation process steps of artificial jade are:

[0035] (1) Establish a three-dimensional model of artificial jade products;

[0036] (2) Obtain the slice data in the Z direction according to the three-dimensional model, and the characteristics are: the thickness of each slice is 0.1mm;

[0037] (3) Weigh various raw materials as required, crush and grind block raw materials;

[0038] (4) Put the powdered raw materials obtained by grinding into a container for mixing and stirring to make the ingredients of the raw materials uniform;

[0039] (5) Put the uniformly mixed raw materials into the powder tank;

[0040] (6) Spread the first layer of powder on the workbench, and then preheat the workbench and powder. The characteristics are: the preheating temperatu...

Embodiment 2

[0044] Example 2: Press figure 1 As shown, the production raw materials and ratio of artificial jade are:

[0045] PbO: 10%

[0046] al 2 o 3 : 80%

[0047] Cr 2 o 3 : 5%

[0048] SiO 2 : 5%.

[0049] The preparation process steps of artificial jade are:

[0050] (1) Establish a three-dimensional model of artificial jade products;

[0051] (2) Obtain the slice data in the Z direction according to the three-dimensional model, and the characteristics are: the thickness of each slice is 0.1mm;

[0052] (3) Weigh various raw materials as required, crush and grind block raw materials;

[0053] (4) Put the powdered raw materials obtained by grinding into a container for mixing and stirring to make the ingredients of the raw materials uniform;

[0054] (5) Put the uniformly mixed raw materials into the powder tank;

[0055] (6) Spread the first layer of powder on the workbench, and then preheat the workbench and powder. The characteristics are: the preheating temperature...

Embodiment 3

[0059] Embodiment 3: press figure 1 As shown, the production raw materials and ratio of artificial jade are:

[0060] PbO: 15%

[0061] al 2 o 3 : 75%

[0062] Cr 2 o 3 : 5%

[0063] SiO 2 : 5%.

[0064] The preparation process steps of artificial jade are:

[0065] (1) Establish a three-dimensional model of artificial jade products;

[0066] (2) Obtain the slice data in the Z direction according to the three-dimensional model, and the characteristics are: the thickness of each slice is 0.1mm;

[0067] (3) Weigh various raw materials as required, crush and grind block raw materials;

[0068] (4) Put the powdered raw materials obtained by grinding into a container for mixing and stirring to make the ingredients of the raw materials uniform;

[0069](5) Put the uniformly mixed raw materials into the powder tank;

[0070] (6) Spread the first layer of powder on the workbench, and then preheat the workbench and powder. The characteristics are: the preheating temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com