Tar ammonia water clarification tank slag discharge device

A shipping device and clarification tank technology, applied in loading/unloading, transportation and packaging, and tilt-bearing vehicles, etc., can solve problems such as environmental pollution, and achieve the effects of avoiding secondary pollution, purifying the plant environment, and stabilizing the chassis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

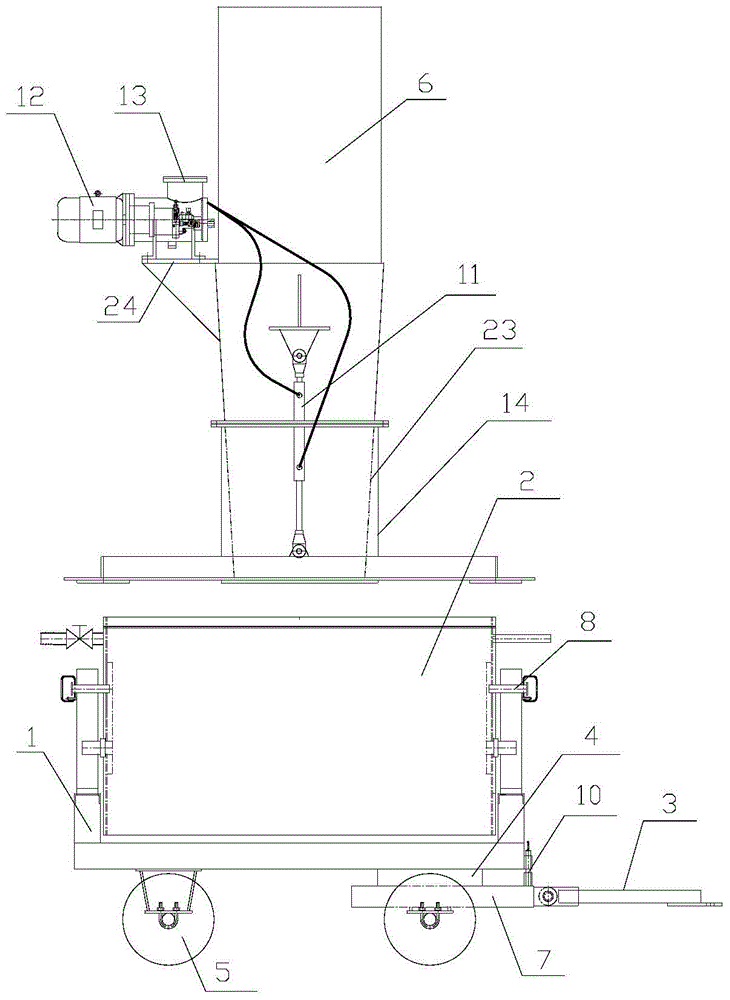

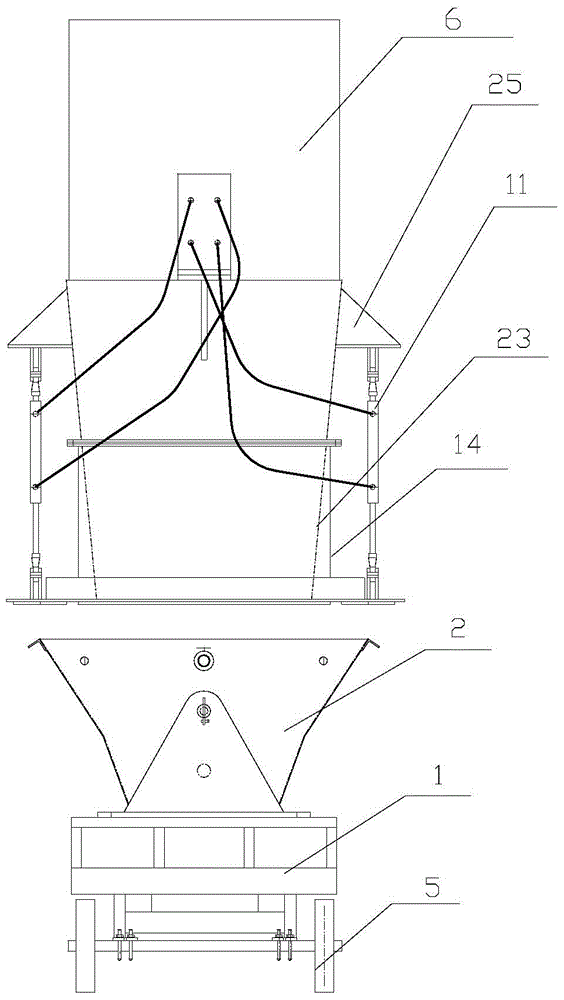

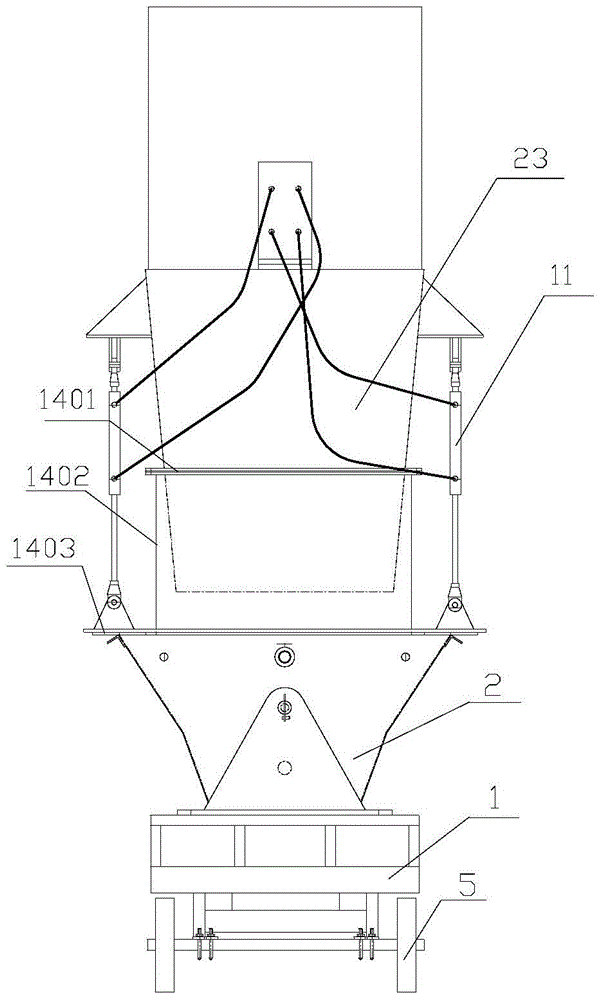

[0070] Such as Figure 1-3 As shown, the embodiment of the present invention discloses a tar ammonia water clarification tank slagging shipping device, including a drive mechanism, a sealing assembly 14 and a casing 2, wherein the sealing assembly 14 includes a sleeve 1402 with open upper and lower ends and a fixed sleeve 1402. The first sealing member 1401 connected to the upper end of the sleeve 1402 and the second sealing member 1403 fixedly connected to the lower end of the sleeve 1402, the first sealing member 1401 surrounds the outer wall of the slagging port 23, and the slagging of the tar ammonia water clarification tank 6 The port 23 extends into the sleeve 1402 through the first sealing member 1401 and the upper opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com