High-strength high-resilience medical TPE (thermoplastic elastomer) tourniquet and preparation method thereof

A high-strength and resilient technology, applied in the field of medical TPE tourniquet and its preparation, can solve the problem of difficulty in obtaining high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Another aspect of the present invention provides a method for preparing a high-strength, high-resilience tourniquet, comprising the following steps:

[0043] (1) After mixing the raw materials by weight, granulate through twin-screw extrusion;

[0044] (2) Vacuum injection molding the product obtained in step (1) into a mold at 170° C. to 200° C., and maintain the injection molding temperature for 8 hours under vacuum conditions, and then cool and solidify.

[0045] In one embodiment, the injection molding temperature in the step (2) is 195°C.

[0046] The applicant unexpectedly found that the cross-linking density of the tourniquet can be further increased by vacuum injection molding and maintaining high temperature under vacuum conditions. This is because graphene oxide contains a large number of carboxyl groups, which can undergo Friedel-Crafts acylation reaction with the benzene ring on the styrene unit in SEBS and MAH-g-SEBS under high temperature and vacuum dehyd...

Embodiment 1~8 and comparative example 1

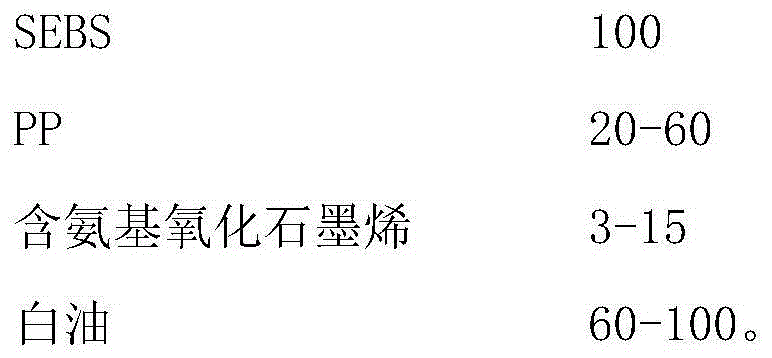

[0067] Prepare high-strength, high-resilience medical TPE tourniquet according to the formula in the following table, and the preparation method is as follows (the consumption of the following components is all parts by weight):

[0068] (1) After mixing the raw materials by weight, granulate through twin-screw extrusion;

[0069] (2) Vacuum injection molding the product obtained in step (1) into a mold at 195° C., and maintain the injection molding temperature for 8 hours under vacuum conditions, and then cool and solidify.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com