Highland barley ice-spring liquor brewing process method

A process method, highland barley technology, applied in the field of brewing technology, can solve the problems of low market share, uneven quality, turbid liquor, etc., and achieve the guarantee of stability and quality, prolonged fermentation time, and full-bodied wine quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

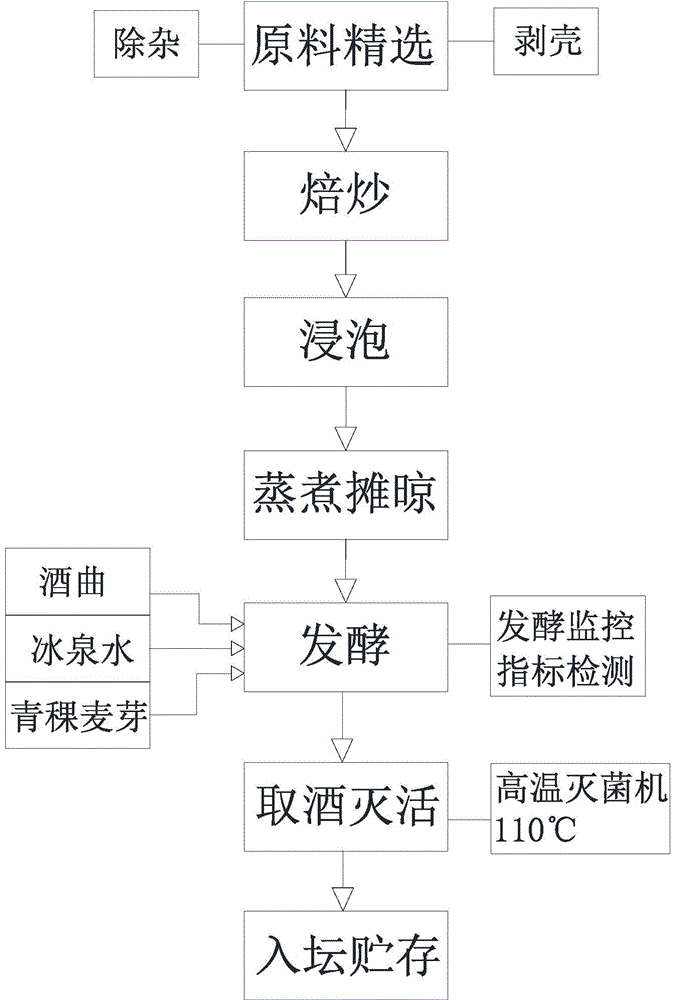

Image

Examples

Embodiment 1

[0038] Embodiment 1: Peel the highland barley, remove sundries, and make the highland barley grains clean; roast the highland barley, pay attention to the firepower to be sharp at the front, slow at the middle, and slow at the end. When the crack rate of the wheat reaches 90%, it has a burnt aroma It can be out of the pot; add germinated barley to the fried highland barley and mix evenly according to the ratio of 19:1, add snow mountain ice spring water to soak, the ice spring water covers the raw material by 15cm, and soak for 48 hours, then pick up the raw material and use Rinse with clean water and drain; add 5°C snow-mountain ice spring water that is twice the amount of highland barley and germinated highland barley to the stainless steel pot, pour the drained highland barley into the pot, cover the pot and put a small amount of steam to cook slowly for 1 hours, until the cracking rate of the highland barley reaches more than 98%, and it is transparent but not rotten; the h...

Embodiment 2

[0039] Embodiment 2: Peel the highland barley, remove sundries, and make the highland barley grains clean; roast the highland barley, pay attention to the firepower to be fast at the front, slow in the middle, and slow at the end. When the crack rate of the wheat reaches 90%, it has a burnt aroma It can be taken out of the pot; add germinated barley to the fried highland barley and mix evenly according to the ratio of 18:2, add snow mountain ice spring water to soak, the ice spring water covers the raw material by 18cm, and the soaking time is 48 hours, then the raw material can be picked up and used Rinse with clean water and drain; add 5°C snow-mountain ice spring water that is 2.5 times the amount of highland barley and germinated highland barley to the stainless steel pot, pour the drained highland barley raw materials, cover the pot and put a small amount of steam to cook slowly for 1 hours, until the cracking rate of the highland barley reaches over 98%, and it is transpa...

Embodiment 3

[0040]Embodiment 3: Peel the highland barley, remove sundries, and make the highland barley grains clean; roast the highland barley, the firepower is fast at the front, slow in the middle, and slow at the end, and when the cracking rate of the wheat reaches 95%, it is taken out of the pan; Add germinated highland barley to the highland barley and mix evenly according to the ratio of 19:1, add snow mountain ice spring water to soak, the ice spring water covers the raw material by 16cm, and the soaking time is 50 hours, then the raw material can be picked up, rinsed with clean water, and drained; Add the amount of highland barley and germinated highland barley to the stainless steel pot, add 5 ℃ snow-capped ice spring water and pour the drained highland barley into the stainless steel pot. Cover the pot and put a small amount of steam to cook slowly for 1 hour until the cracking rate of the highland barley reaches More than 98%, transparent but not rotten; the highland barley out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com