A blowback regeneration device for a diesel particulate filter

A particle trap and regeneration device technology, which is applied in the direction of mufflers, exhaust devices, machines/engines, etc., can solve problems such as low energy utilization rate and complex structure, and achieve simple structure, high regeneration efficiency, and improved economy and the effect of applying the value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

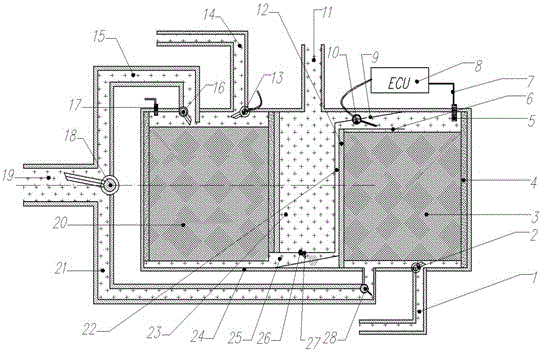

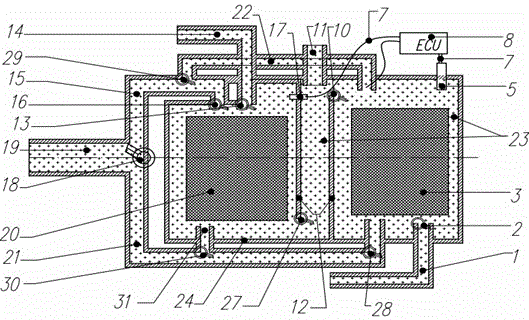

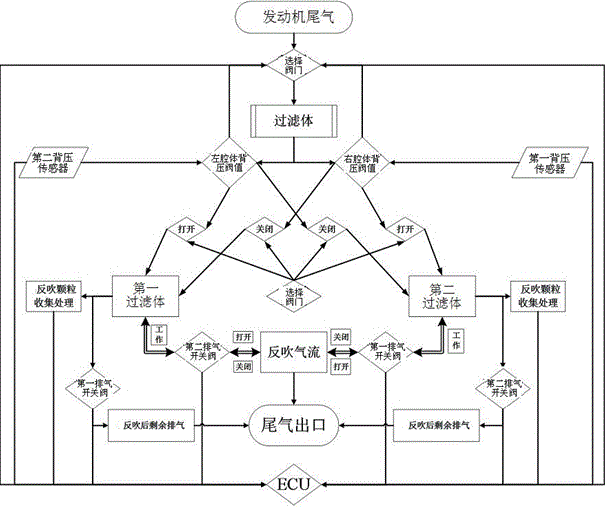

[0023] Refer to attached figure 1 and 2 As shown, the present invention specifically relates to a blowback regeneration device for a diesel particulate filter, which includes two filter bodies and a filter body housing 24. The right three chambers, the left chamber communicates with the lower end of the middle chamber, the middle chamber communicates with the upper end of the right chamber, the first filter body 3 is fixed in the right chamber, the second filter body 20 is fixed in the left chamber, and the middle chamber It is the muffler cavity 23, and the muffler cavity 23 communicates with the outside world through the exhaust main pipe 11. The left chamber and the right chamber are provided with air intake branch pipes and blowback particle collection pipes, and the left chamber and the right chamber are provided with The inlet ends of the intake branch pipes converge into a main intake pipe 19; by rationally designing the pipeline circuit, a back-blowing airflow pipe 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com