Mounting structure of auxiliary engine

An installation structure and engine technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve problems such as weight increase and cost increase, and achieve the effect of avoiding weight increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

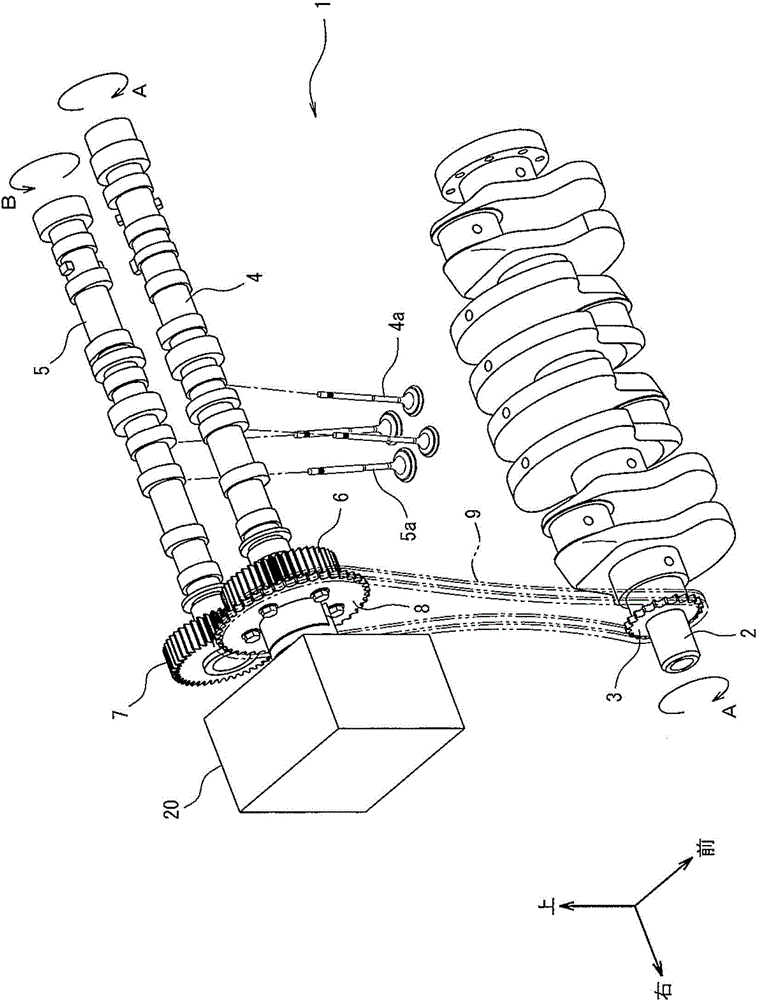

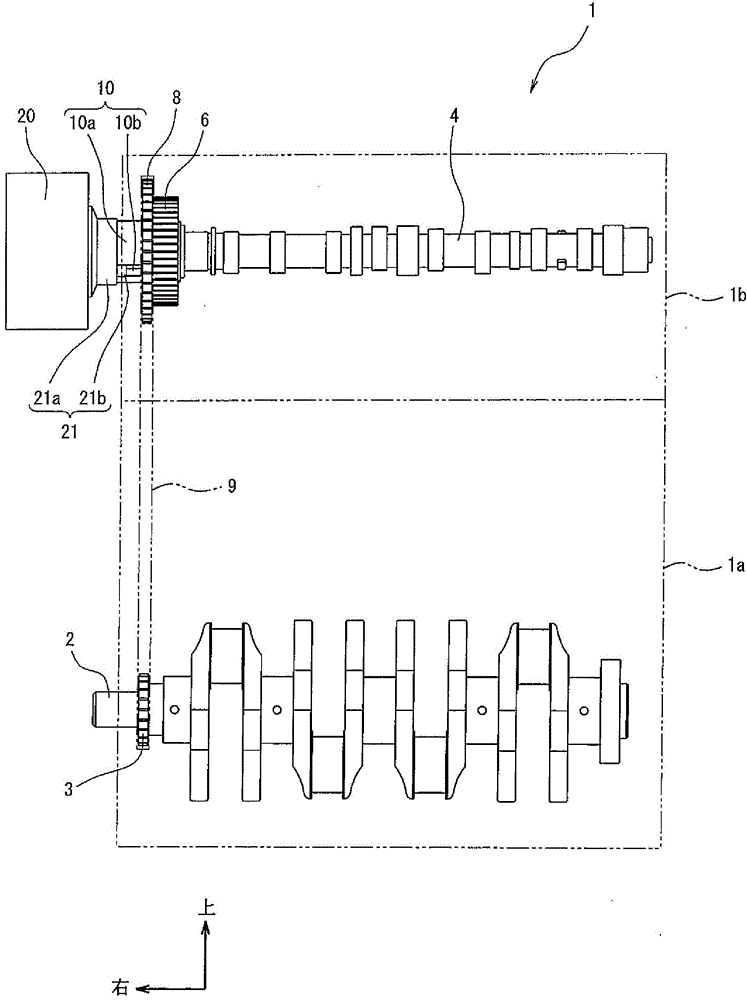

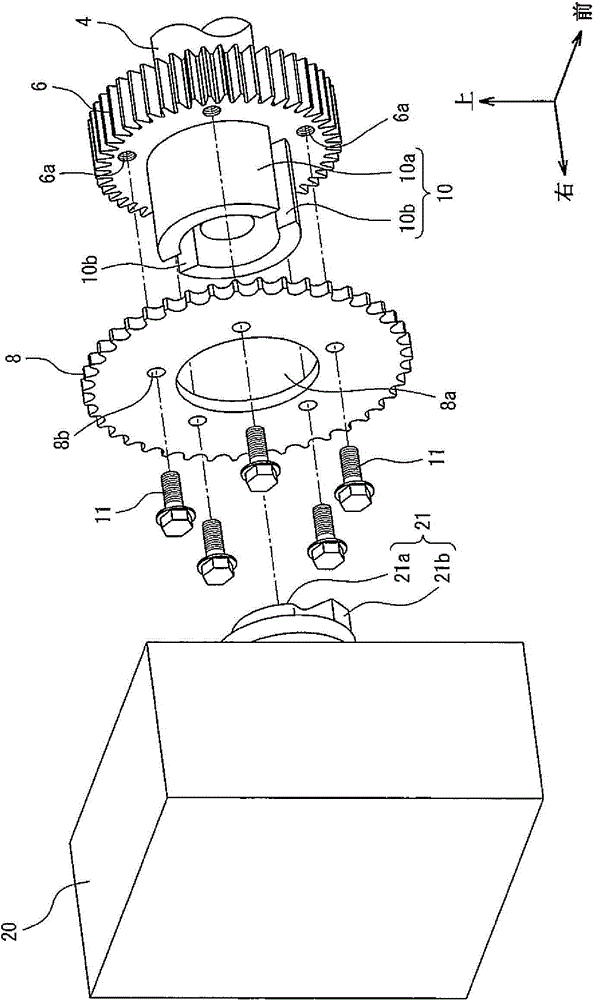

[0026] The details of the attachment structure of the engine auxiliary machine according to the embodiment of the present invention will be described below with reference to the drawings. Figure 1 to Figure 4 It is a figure which shows the attachment structure of the engine auxiliary machine which concerns on embodiment of this invention.

[0027] First, the configuration will be described. exist figure 1 , figure 2 Among them, an auxiliary engine 20 is installed in the engine 1 , and the auxiliary engine 20 is driven by power generated by the engine 1 . In the present embodiment, the auxiliary engine 20 is a high-pressure fuel pump for pressurizing fuel to a fuel injector (not shown) or a vacuum pump for generating negative pressure.

[0028] The engine 1 is an inline 4-cylinder DOHC (Double OverHead Camshaft: double overhead camshaft) type engine, and is arranged transversely at the front of a vehicle (not shown). Here, in this embodiment, the arrows shown together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com