Detection method of interface morphology of multilayer bonded structure

A detection method, a bonding technology, applied in the processing of the response signal of the detection, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

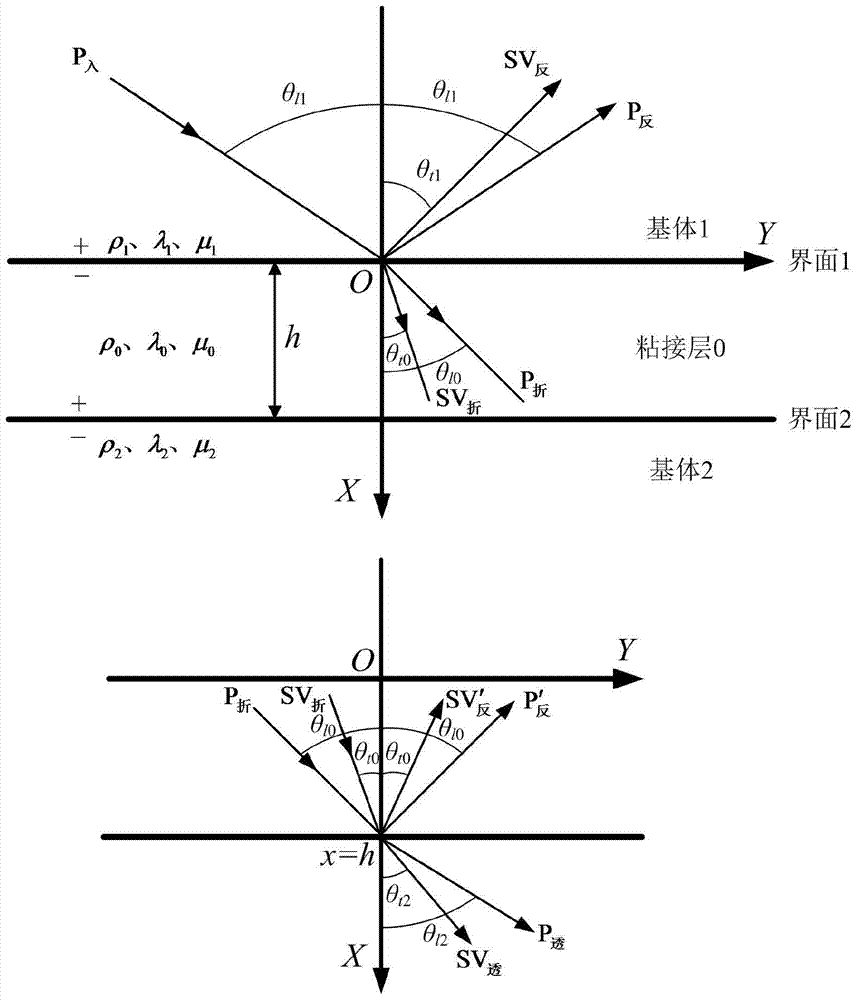

[0070] This implementation case includes the following steps:

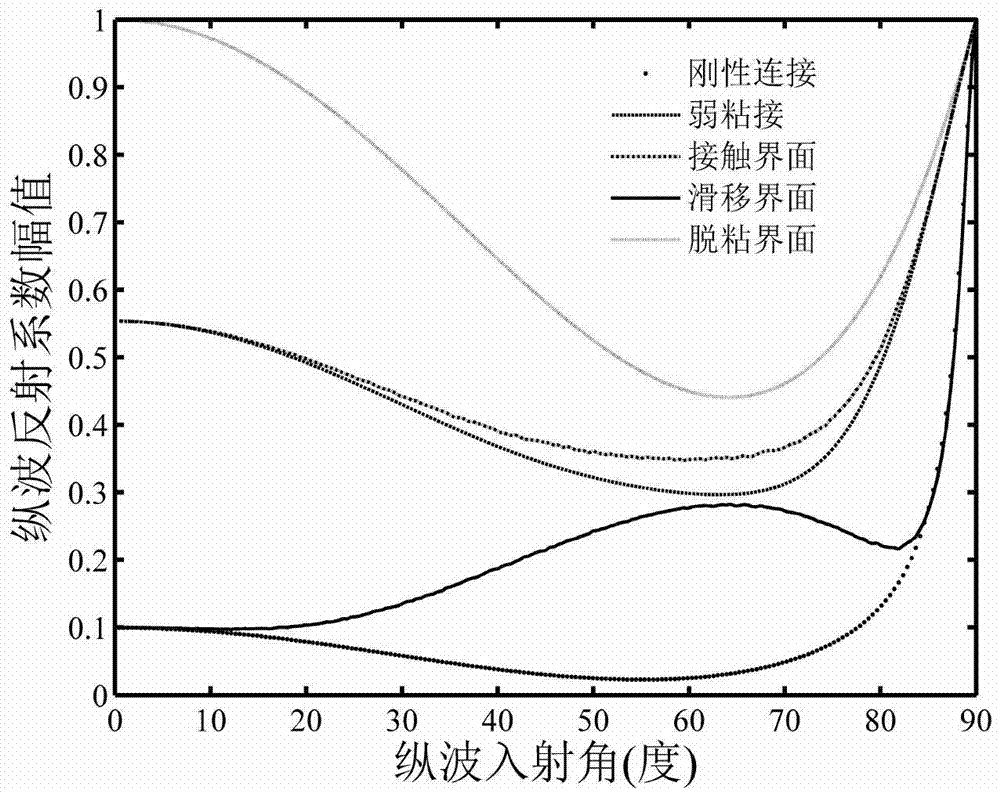

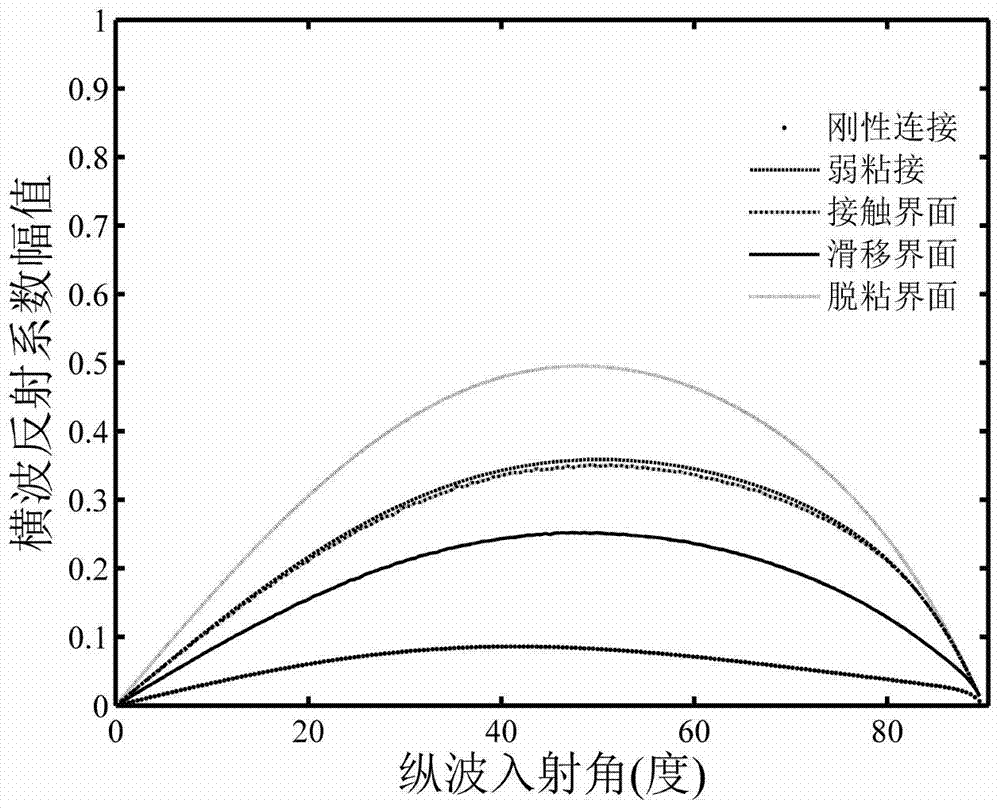

[0071] 1) If the frequency f of the longitudinal wave is 1 MHz, and the thickness h of the adhesive layer is 0.02 mm, these two parameters are substituted into the four equations of the expression (11) in step 1.9. Order K N (2) =8×10 16 (N / m 3 ), K T (2) =3×10 16 (N / m 3 ) indicates that interface 2 of the bonded structure is a rigid connection interface. Order K N (1) =8×10 16 (N / m 3 ), K T (1) =3×10 16 (N / m 3 ) indicates that the interface 1 of the bonded structure is a rigid connection interface; let K N (1) =7×10 13 (N / m 3 ), K T (1) =3×10 12 (N / m 3 ) indicates that the interface 1 of the bonding structure is a weakly bonding interface; let K N (1) =8×10 16 (N / m 3 ), K T (1) → 0 means that the interface 1 of the bonded structure is a slip interface; let K N (1) =7×10 13 (N / m 3 ), K T (1) → 0 means interface 1 of the bonded structure is the contact interface; let K N (1) →0,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com