Cooling system for power battery of new-energy bus and new-energy bus

A power battery and cooling system technology, which is applied in the arrangement of the cooling combination of the power unit, power unit, secondary battery, etc., can solve the problems of being in a cooling state, endangering the safety of passengers, and intensifying combustion with oxygen-enriched air, so as to ensure the safety of passengers Effects of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

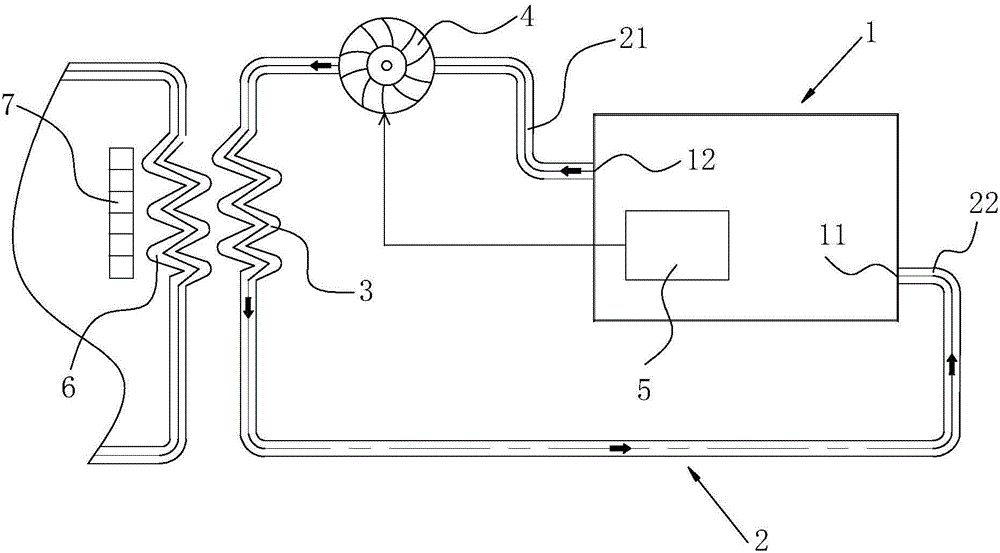

[0039] Such as figure 1 As shown, a power battery cooling system for a new energy bus includes a battery box 1 and a circulating air duct 2 communicating with the battery box 1. The battery box 1 and the circulating air duct 2 form a closed cavity, and the cavity is filled with There is a cooling medium, and the circulating air duct 2 is provided with a radiator 3 for heat exchange. The radiator 3 is installed on the side away from the battery box 1, and the radiator 3 is arranged close to the evaporator 6 of the external air conditioning system. The circulating air A driving fan 4 is arranged on the road 2 and between the battery box 1 and the radiator 3 . In this embodiment, the driving fan 4 is installed between the air outlet 12 and the radiator 3 . The radiator 3 is arranged on the leeward side of the evaporator 6 of the external air conditioning system. Specifically, the normal-temperature air passes through the evaporator 6 of the external air-conditioning system to fo...

Embodiment 2

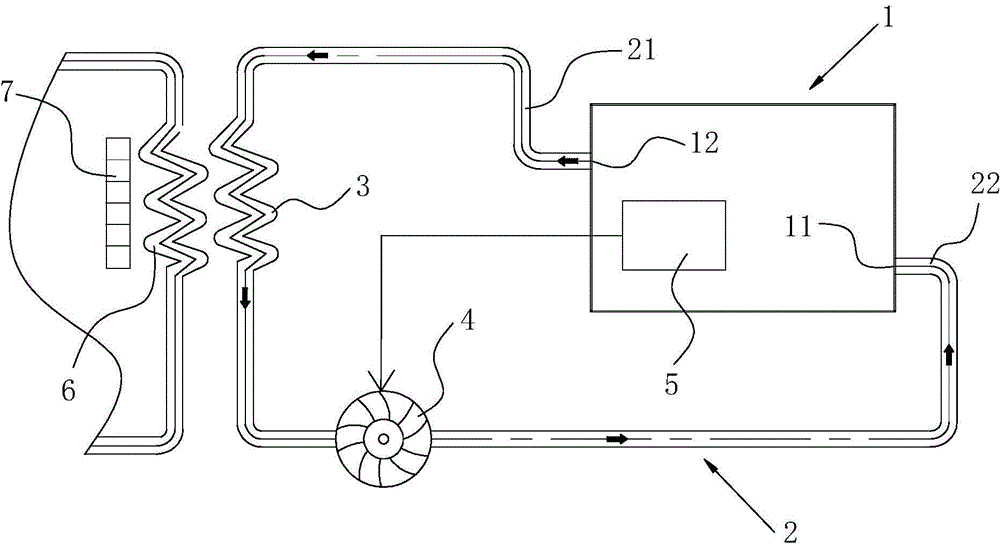

[0046] The difference between this embodiment and Embodiment 1 is:

[0047] Such as figure 2 As shown, the driving fan 4 is installed between the air inlet 11 and the radiator 3, and the cooling medium is neon gas.

Embodiment 3

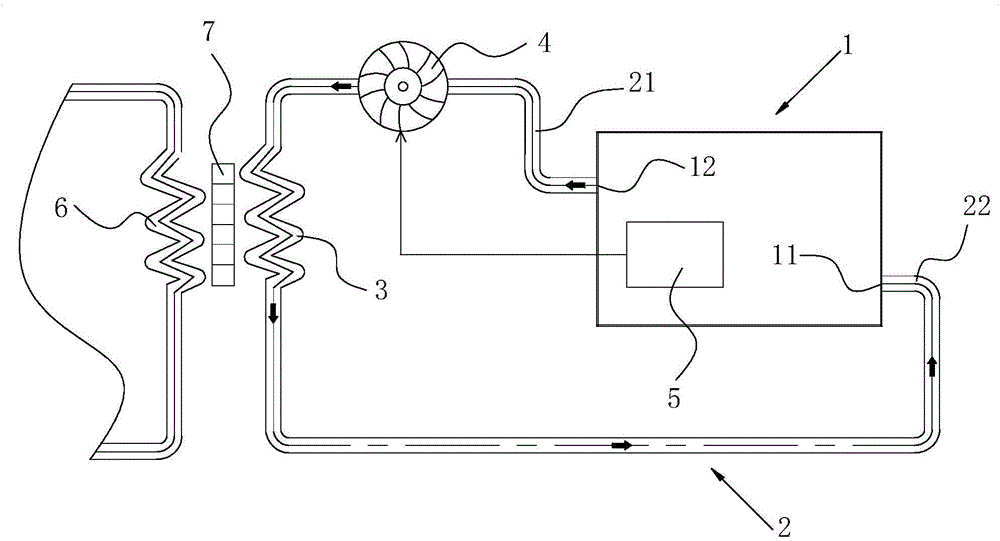

[0049] The difference between this embodiment and Embodiment 1 is:

[0050] Such as image 3 As shown, the evaporator 6 is arranged on the windward side of the axial flow fan 7, the radiator 3 is arranged on the side of the axial flow fan 7 away from the evaporator 6, and the cooling medium is argon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com