A lithography illuminator that is telecentric in both directions

An illuminator and concentrator technology, applied in the field of illuminators, can solve the problems of increasing sensitivity, complicated adjustment of illuminators, etc., and achieve the effect of increasing sharpness and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] General description of the illuminator

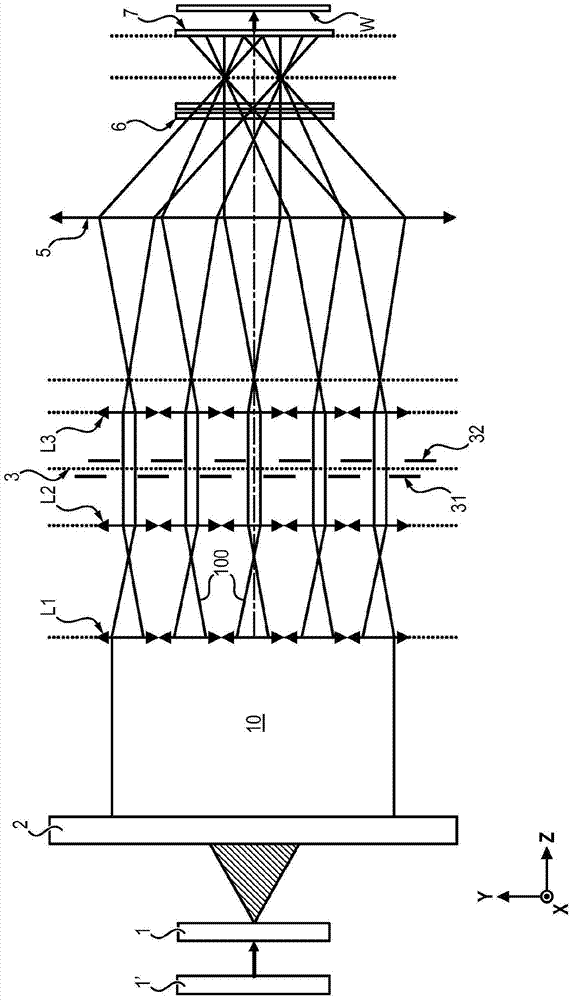

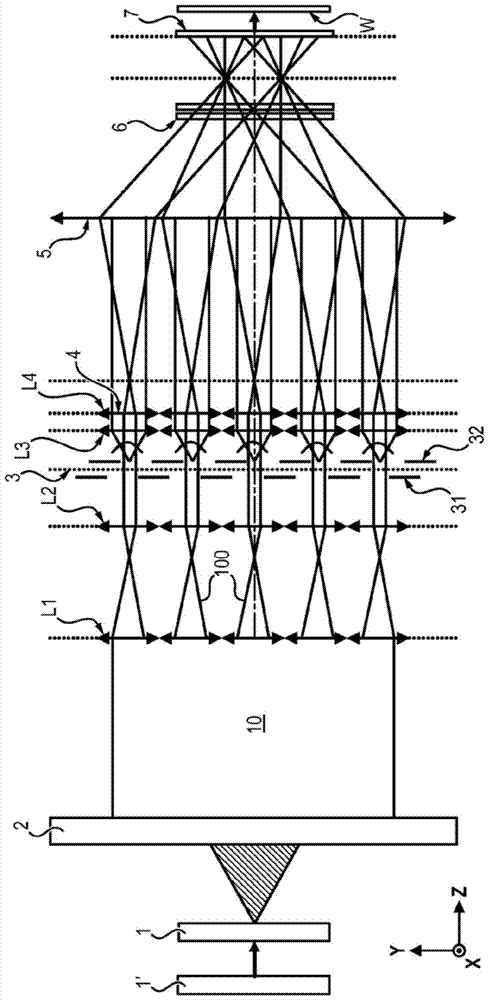

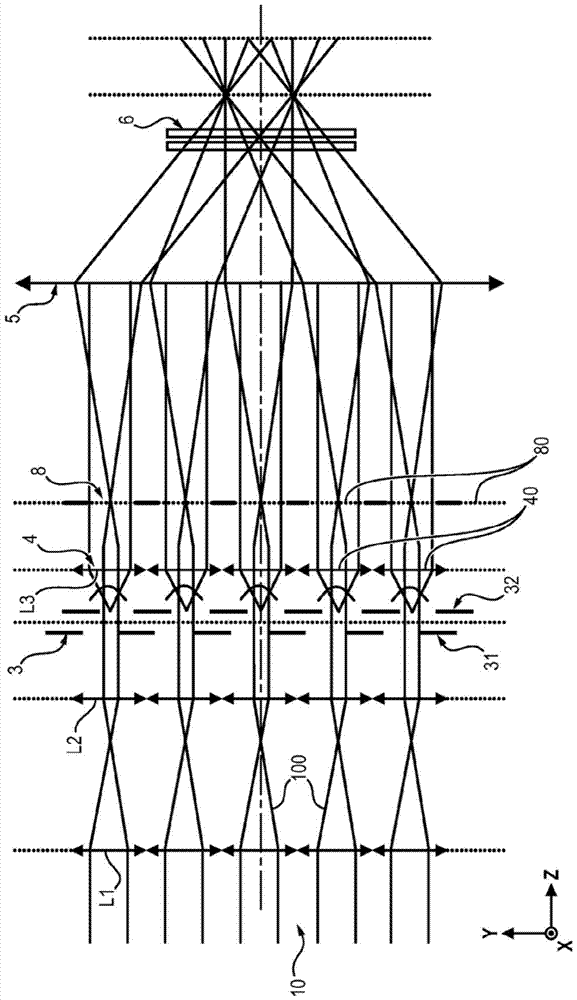

[0051] Figure 2a , 2b and 2c schematically show a part of an illuminator according to the invention.

[0052] exist Figure 2a In, the illuminator comprises: a light source 1' of a light beam 10, such as a laser light source; a diffractive element 1, which is located at the output of the light source 1'; and a zoomer 2 (these elements are not shown in Figure 2b with Figure 2c middle).

[0053] It further comprises an afocal system L1L2, at the output of the zoomer 2, consisting of a first and a second microlens array L1 and L2.

[0054] Beam 10 comprises a plurality of sub-beams 100 at the output of afocal system L1L2, forming a sub-exit pupil of afocal system L1L2.

[0055] The illuminator comprises a shutter 3, shown as two grids 31, 32, and located at the exit pupil of the afocal system L1L2.

[0056] The light homogenizing system 4 is located downstream of the shutter 3, so that the shutter 3 is located on the objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com