Watermelon pulp-taking dicer

A dicing machine and watermelon technology, applied in application, food processing, food science and other directions, can solve the problems of increased processing cost, unsightly eating watermelon, unclean and hygienic, etc., and achieves long transmission distance, high degree of automation, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

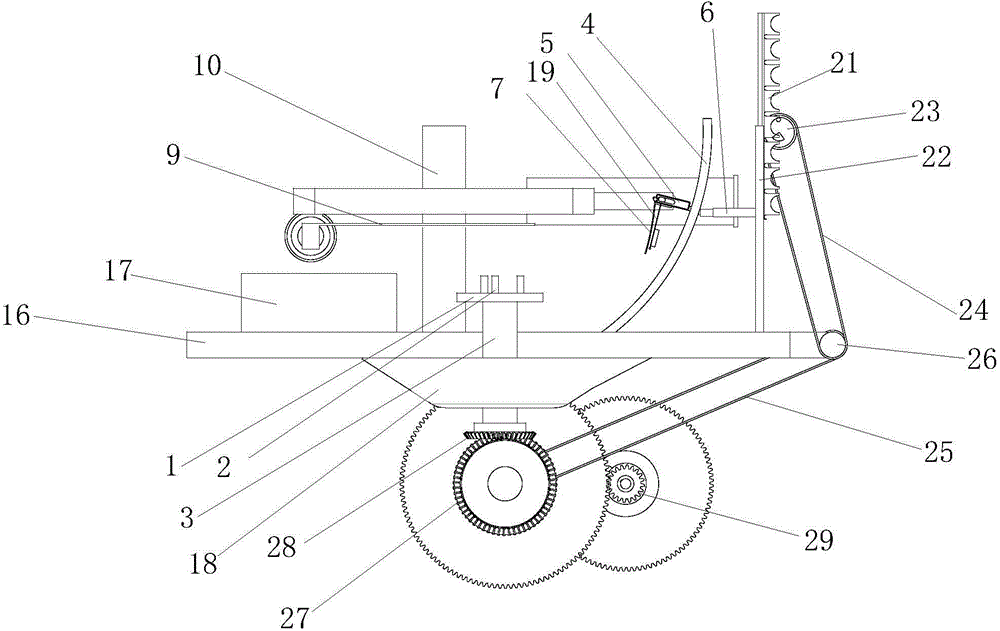

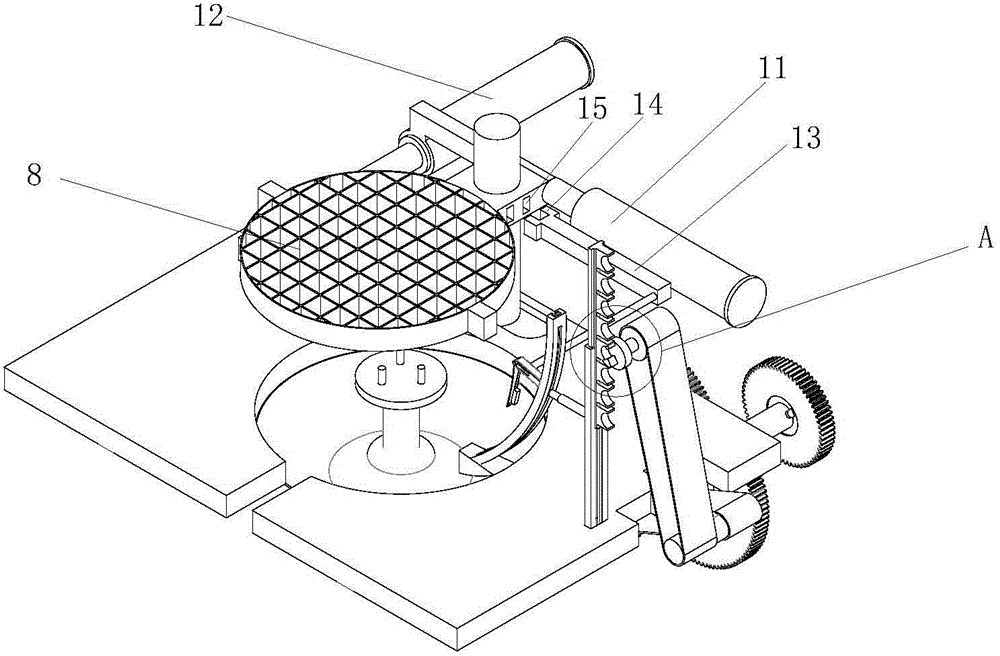

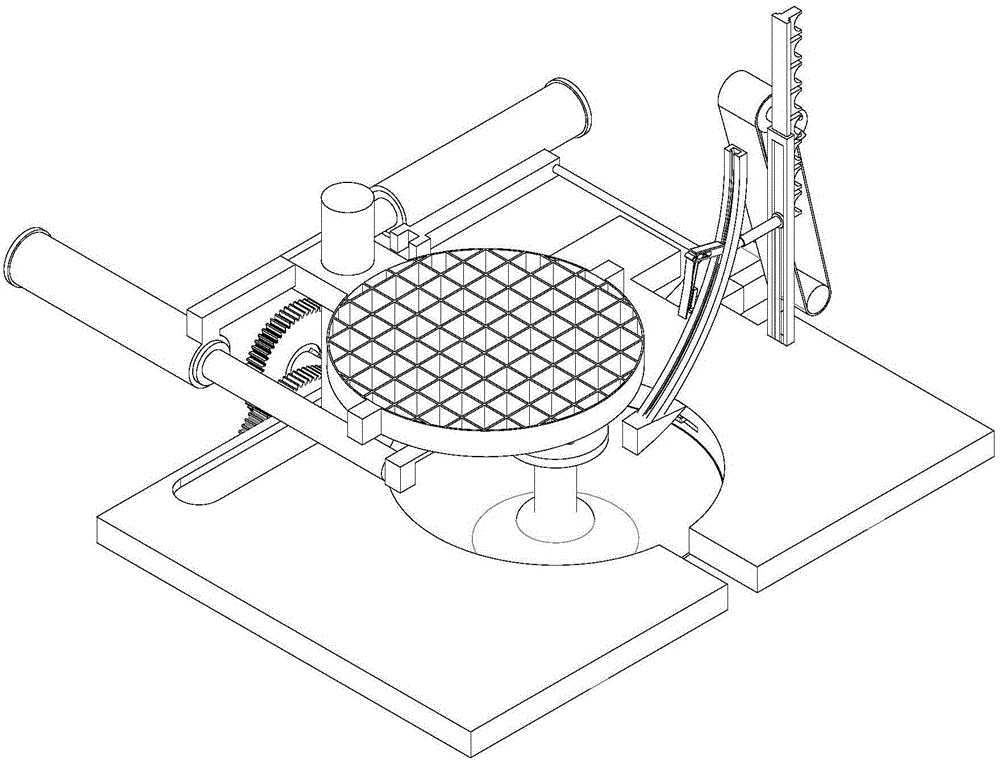

[0042] As shown in the accompanying drawings, the present invention provides a watermelon pulp and slicer, including an execution system, a power system, a collection system and a control system,

[0043]The executive mechanism includes a fixed chassis 1, a pulp-taking device and a cutting device; the fixed chassis 1 is a disc, and three fixed columns 2 extend upward from the upper surface of the fixed chassis 1, and the lower surface of the chassis faces A support rod 3 extends downward, and the axis of the support rod 3 coincides with the axis of the fixed chassis 1, and the fixed column 2 is evenly arranged on the upper surface of the fixed chassis 1; the second bevel gear 28 and The lower end of the support rod 3 is fixedly connected coaxially, and the fixed chassis 1 can rotate along the axis driven by the second bevel gear 28;

[0044] The pulp removing device is arranged on the peripheral side of the fixed chassis 1, and the pulp removing device includes an arc-shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com