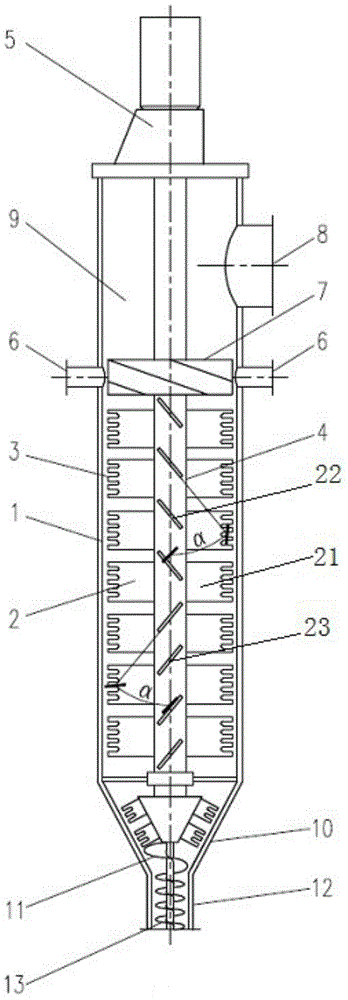

Film evaporator for cellulose dissolving

A thin film evaporator, cellulose dissolution technology, applied in evaporator accessories, dissolution, evaporation and other directions, can solve the problems of NMMO and cellulose decomposition, high dissolution temperature vacuum conditions, slow film surface renewal, etc., to achieve easy cellulose dissolution. , the effect of increasing the amount of dissolution, increasing the update frequency and the degree of update

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

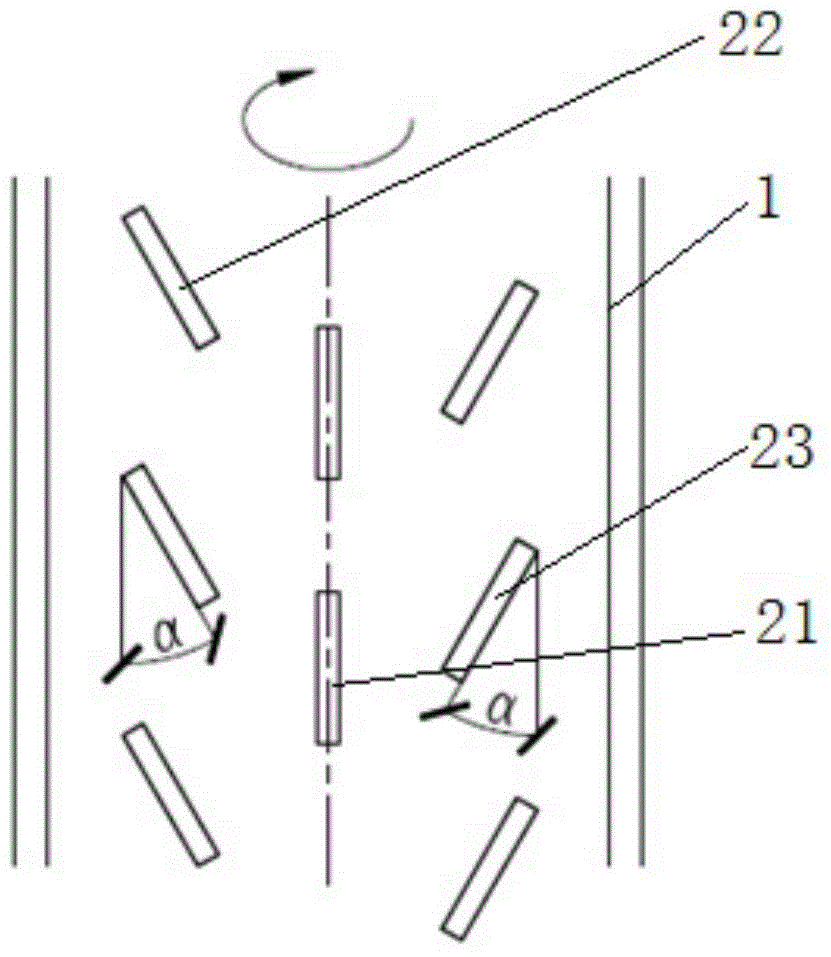

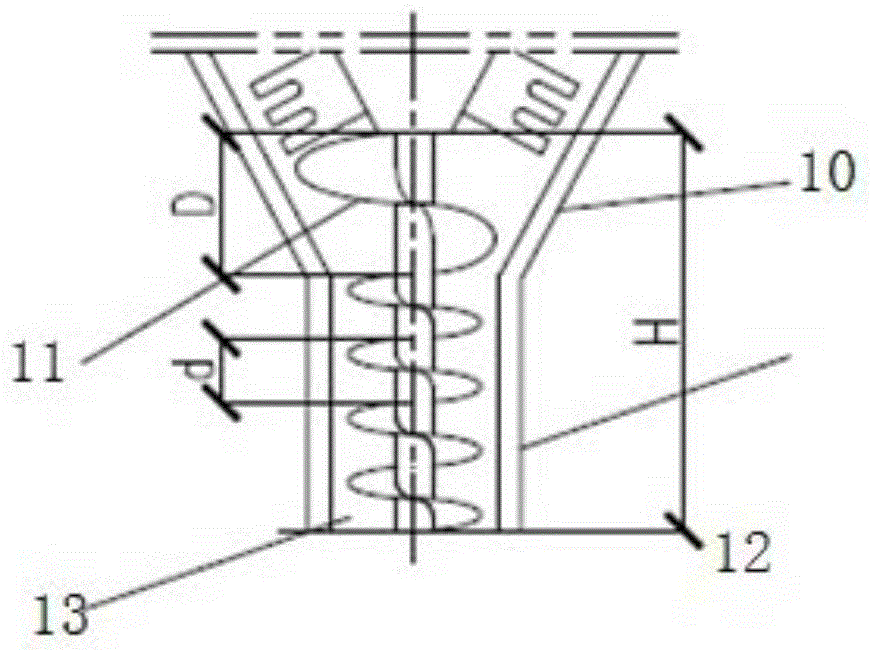

[0055] A thin film evaporator with an evaporation area of 1m 2 , the number of scraper rows is 12, of which there are 6 rows of scrapers arranged vertically, among the other 6 rows of scrapers arranged obliquely, 2 rows have an angle α of -3°, and the remaining 4 rows have an angle α of 25°. There are 3 teeth on each scraper, the tooth length is 30mm, the tooth length to gap ratio is 1.5:1, the distance between the scraper and the inner wall is 3mm, and the arc length of the scraper section is 40mm. The length of the discharge spiral at the bottom is 300mm, the spiral pitch of the cone section is 60mm, and the spiral pitch of the straight section is 30mm.

[0056]Based on the cellulose percentage of 12%, on the production line of Lyocell fiber with NMMO and water as the solvent, the maximum production capacity of Lyocell fiber can reach 300 tons per year using this thin film evaporator, and the dissolution capacity of the thin film evaporator can reach 0.32 tons / h, the resi...

Embodiment 2

[0061] A thin film evaporator with an evaporation area of 30m 2 , the number of scraper rows is 24, of which there are 12 rows of scrapers arranged vertically, and among the other 12 rows of scrapers arranged obliquely, 4 rows have an angle α of -5° and are distributed in the lower half, and the remaining 8 rows and The upper half of the scraper column with an angle of -5° is a scraper with an angle α of 20°. The ratio of tooth length to gap on the scraper is 1.5:1, the distance between the scraper and the inner wall is 4mm, and the arc length of the scraper section is 100mm. The length of the bottom discharge screw is 450mm, the screw pitch of the cone section is 80mm, and the screw pitch of the straight section is 50mm.

[0062] Based on the cellulose percentage of 12%, on the production line of Lyocell fiber with NMMO and water as solvent, using this thin film evaporator, the maximum production capacity of Lyocell fiber can reach 8,000 tons / year, and the dissolution capa...

Embodiment 3

[0067] A thin film evaporator with an evaporation area of 35m 2 , the number of scraper columns is 24, of which there are 12 rows of vertical scrapers, and among the other 12 rows of oblique scrapers, 2 rows have an angle α of -10° and are distributed in the lower half, and the remaining 10 rows and The upper half of the scraper column with an angle of -10° is all scrapers with an angle α of 15°. The ratio of tooth length to gap on the scraper is 1.8:1, the distance between the scraper and the inner wall is 5mm, and the arc length of the scraper section is 150mm. The length of the bottom discharge screw is 500mm, the screw pitch of the cone section is 100mm, and the screw pitch of the straight section is 80mm.

[0068] Based on a cellulose percentage of 12%, on the production line of Lyocell fibers with NMMO and water as solvents, using this thin film evaporator, the maximum production capacity of Lyocell fibers is 10,000 tons / year, and the film evaporator has a dissolving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com