Apparatus utilizing heat energy generated during platinum catalytic hydrogenation in cyclohexanone production for dehydrogenation technology

A technology of platinum catalysis and cyclohexanone, which is applied in the chemical industry to achieve the effects of reduced energy loss, reduced losses, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

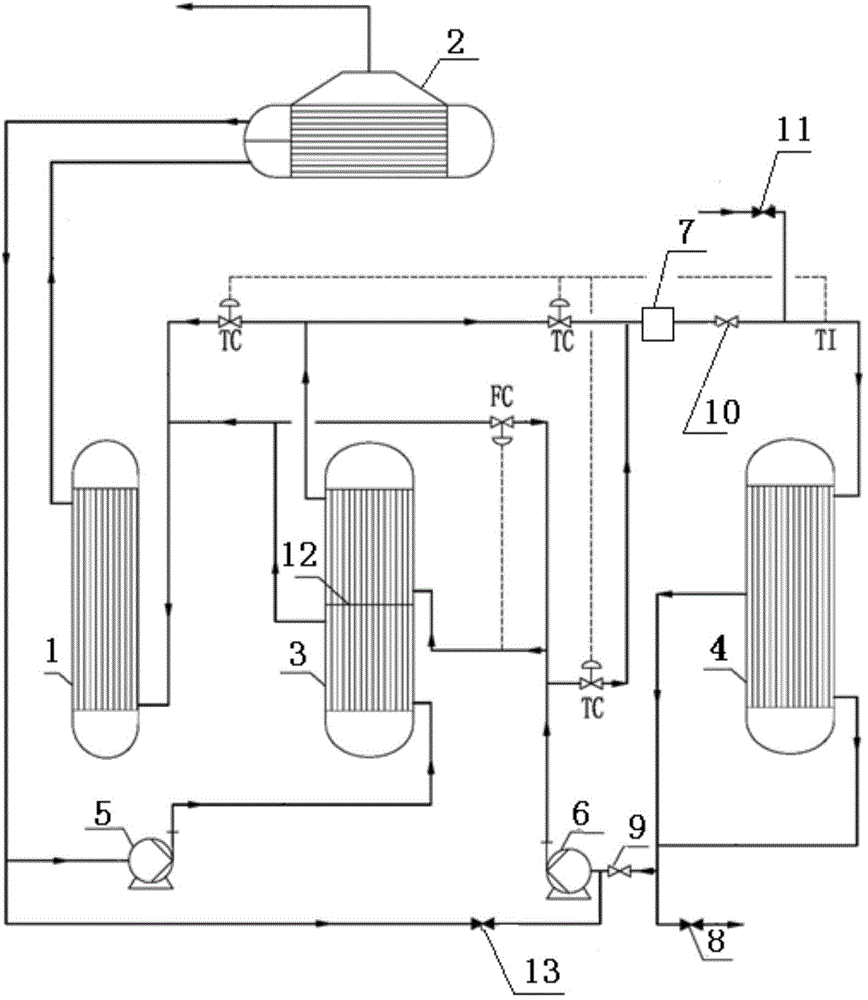

[0031] Such as figure 1 Shown, a kind of device that cyclohexanone produces the heat energy that platinum catalytic hydrogenation produces is used for dehydrogenation process, and this device comprises benzene evaporator (1), steam generator (2), hydrogenation reactor (3), dehydrogenation process Hydrogen reactor (4), hydrogenation thermal oil circulation pump (5) and dehydrogenation thermal oil circulation pump (6), wherein:

[0032] The heat transfer oil output end of the upper part of the benzene evaporator (1) is connected to the steam generator (2), and one heat transfer oil output end of the steam generator (2) is connected to the hydrogenation hot oil circulation pump (5) and the dehydrogenation heat pump (5) respectively. The oil circulation pump (6) is connected;

[0033] The heat transfer oil output end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com