Application method of plating crystal liquid used for painted surfaces and hubs of automobile

A technology for plating liquid crystal and automotive paint, which is applied to devices and coatings that apply liquid to the surface. Stain, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

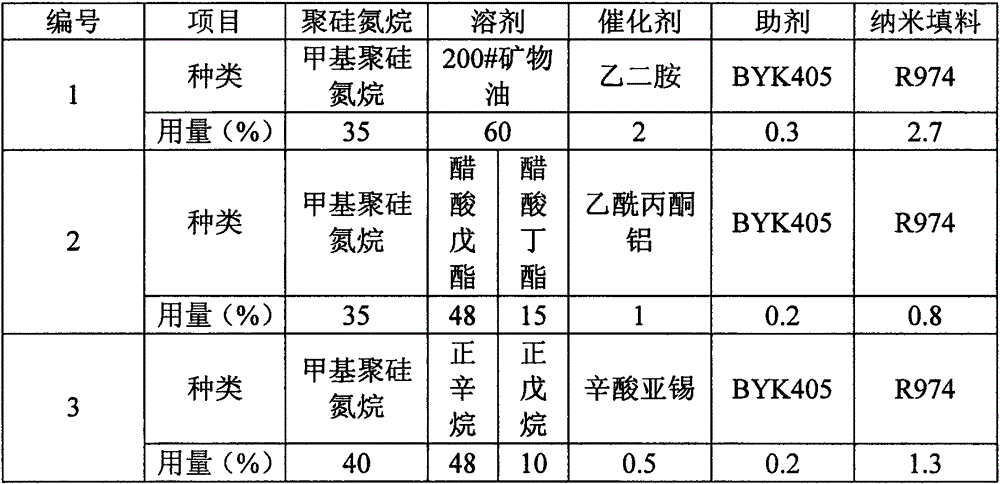

Embodiment 1

[0060] The vehicle is a black Jetta, which is 4 years old. The body has been washed and degreased, and the necessary parts are polished. After washing, it is dried to a dry state. Use No. 1 crystal plating solution to construct different parts of the car body. The construction is carried out area by area, each area is 50cm*50cm. Pour the crystal plating liquid on the sponge, wipe it horizontally and vertically, let it dry and use a towel to wipe off the residual liquid on the surface, and wipe off the traces formed during the curing process until the surface is smooth. After the crystal plating is completed, the vehicle can be used normally after standing still for 2 hours. After further crystallization and solidification for 3 days, the effect was tested. The brightness of the car body is improved, the surface scratches are reduced, and the paint film shows good hydrophobic properties.

Embodiment 2

[0062] Gray Mazda 6, 3 years old, the rear part of the car was washed, degreased, and dried. Half of the car rear part adopts No. 2 crystal plating liquid to carry out crystal plating, and the crystal plating method is the same as embodiment 1, and the other half keeps the original appearance. After 3 days of crystallization and solidification, it is realized by splashing water. The paint surface after crystal plating obviously exhibits hydrophobic characteristics, while the paint surface without crystal plating has water flow spreading and has no hydrophobic characteristics.

Embodiment 3

[0064] Blue Toyota, 1 year old, after cleaning the car body, use No. 3 crystal plating solution to carry out crystal plating according to Example 1. After the crystal is solidified, the brightness of the car body is improved. After one year of normal use, the water splashing test shows that the paint surface still shows obvious hydrophobic properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com