Machine tool and method for processing slender shaft parts

A technology of parts processing and processing methods, which is applied in the fields of CNC combined machine tools, machining manufacturing and automation, can solve the problems of low processing accuracy, difficult to guarantee processing accuracy, and poor product processing consistency, so as to improve production efficiency and production capacity, processing Good consistency and guaranteed machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

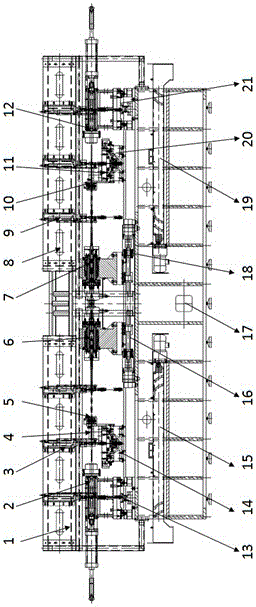

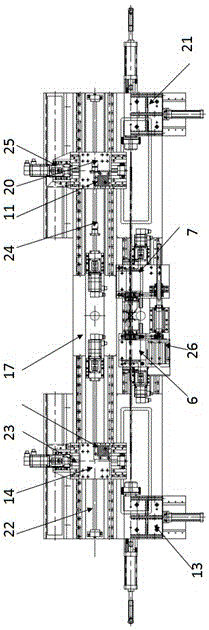

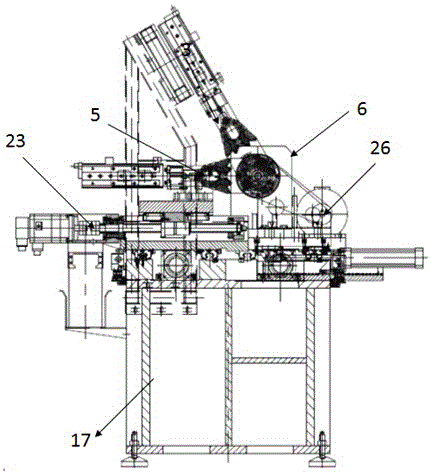

[0037] Such as figure 1 , 2 , 3, used for processing slender shaft parts, including the left clamping manipulator mounting seat 1, the left tail clamping mechanism 2, the left clamping manipulator 3, the left tool rest 4, and the left heel tool Manipulator unit 5, left headstock 6, right headstock 7, right clamping manipulator mount 8, right clamping manipulator 9, right follower manipulator unit 10, right tool rest 11, right tail clamp Pulling mechanism 12, slide table 13 of left tail clamping mechanism, left X-axis slide table 14, left chip conveyor 15, left Z2-axis transmission unit 16, frame 17, right Z2-axis transmission unit 18, left Side chip conveyor 19, right X-axis slide table 20, right tail clamping mechanism slide table 21, left Z1-axis transmission unit 22, left X-axis transmission unit 23, right Z1-axis transmission unit 24, right side X-axis transmission unit 25, main motor 26;

[0038]On the middle position of frame 17, left headstock 6 and right headstock 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com