Wall-climbing robot with wall surface polishing function

A wall-climbing robot and wall surface technology, applied in the field of wall-climbing robots, can solve the problems of low grinding efficiency and achieve the effects of simple structure, low weight and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

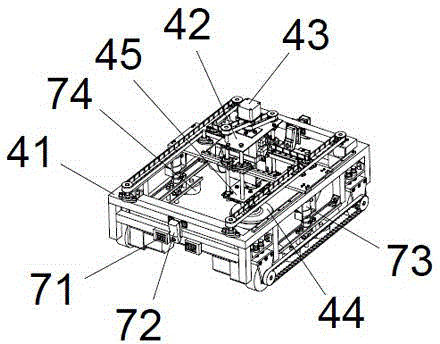

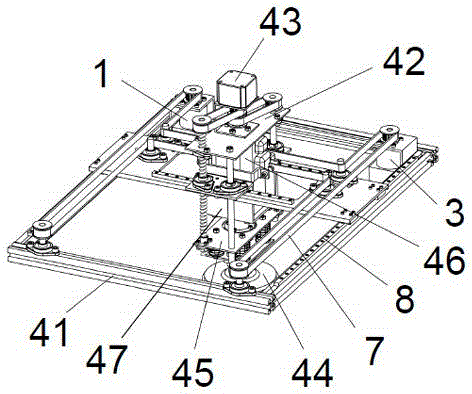

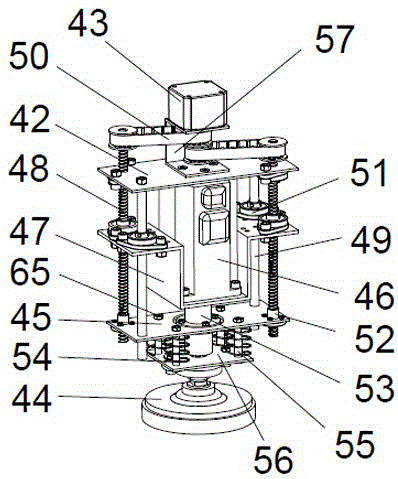

[0033] With reference to accompanying drawing, a kind of wall surface grinding wall-climbing robot is equipped with action device, grinding device on frame 41, and grinding device is installed on the two-degree-of-freedom moving device;

[0034] The two-degree-of-freedom mobile device includes a stepping motor, a synchronous belt, a slide rail, a slide plate and a working slide block. Y-direction slide rails 8 are arranged on both sides of the frame, and chute slots are provided at the lower end of the slide plate 12 corresponding to the two Y slide rails. 81. The slide plate and the slide rail are connected through the structure of the slider chute; two synchronous motors 1 and 3 are respectively installed on the same side of the two Y-direction slide rails, and two reversing wheels 9 and 10 are respectively installed on the two Y-direction slide rails. To the other side of the slide rail, four transmission bushings 4, 5, 13, 14 are fixed on the slide plate; two ends of a sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com