Automatic cover screwing assembling machine

An assembly machine and automatic technology, which is applied in the direction of screw caps, etc., can solve the problems of fluid leakage, human inability to unscrew and open, etc., and achieve the effects of high efficiency and cleanliness, good assembly quality of screw caps, easy translation positioning and automatic switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will now be described in further detail with reference to the drawings and embodiments. These drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, and therefore only show the constitutions related to the present invention.

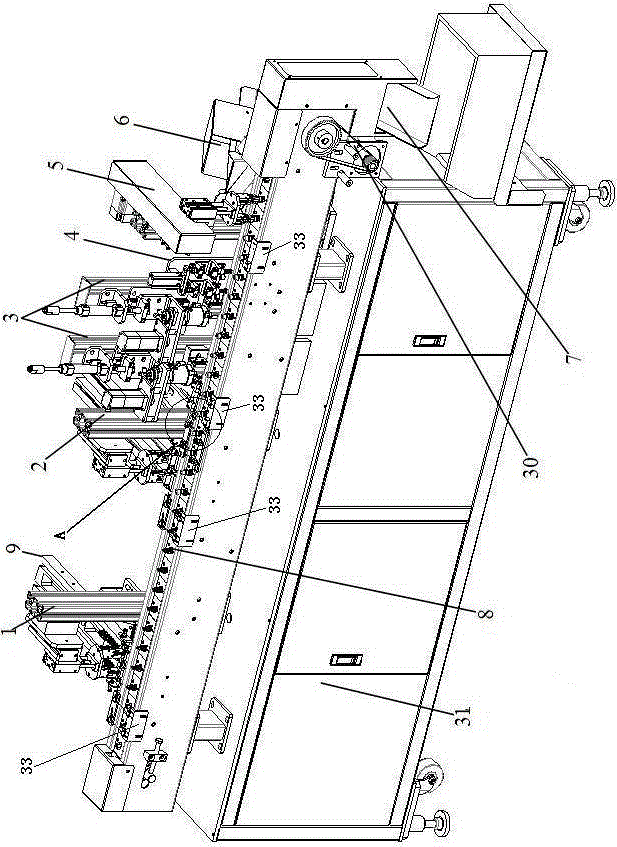

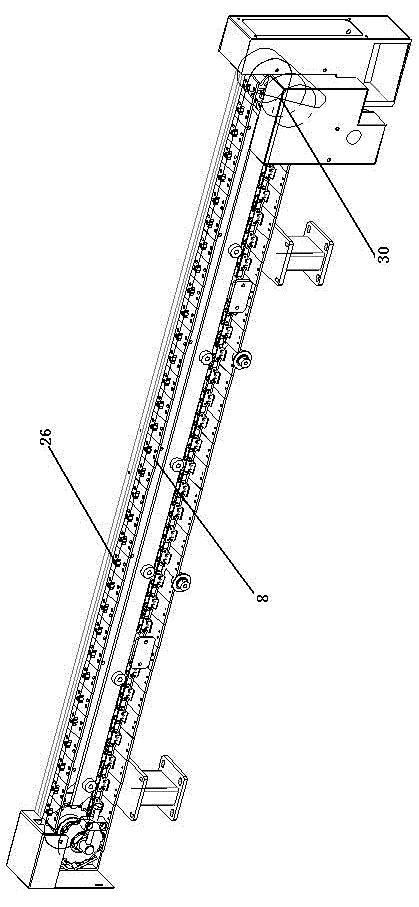

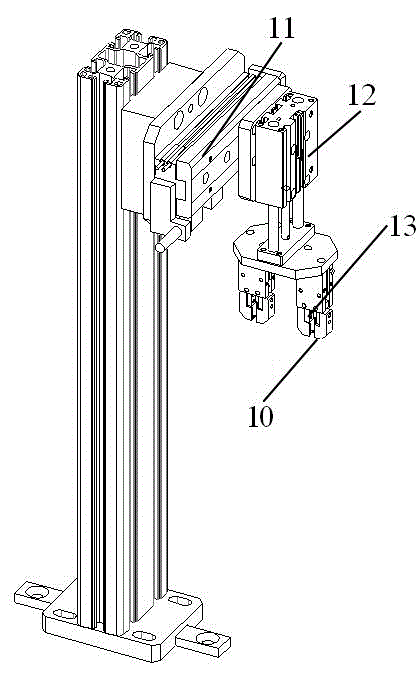

[0033] Such as figure 1 with figure 2 As shown, an automatic capping assembly machine includes: a chain plate conveyor line 8 and the stations connected by the chain plate conveyor line 8 are: suction nozzle 28 feeding manipulator 1, screw cap 27 feeding manipulator 2, automatic The capping device 3, the detection unit 4, and the unloading manipulator 5. The chain conveyor line 8 is provided with positioning elements 26 at equal intervals. The unloading manipulator 5 connects the finished product blanking slide 6 and the chain conveyor line 8, chain plate type The end of the conveying line 8 is connected with the unqualified product blanking chute 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com