Grinding aid feeding method

A feeding method and technology of grinding aid, which are applied in the field of chemical building materials, can solve the problems of difficulty in adjusting the formula of cement grinding aid, uneven mixing of grinding aid and clinker, etc. The effect of promoting the mixed state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A, prepare triethanolamine grinding aid mother liquor by conventional method;

[0018] B. Dilute the grinding aid mother liquor triethanolamine and water according to different volume ratios to obtain a diluent;

[0019] C. The diluent is added to the small grinding system of the laboratory, and the cement used is P.O32.5 cement of Esheng Cement Plant, clinker (95%), and gypsum (5%).

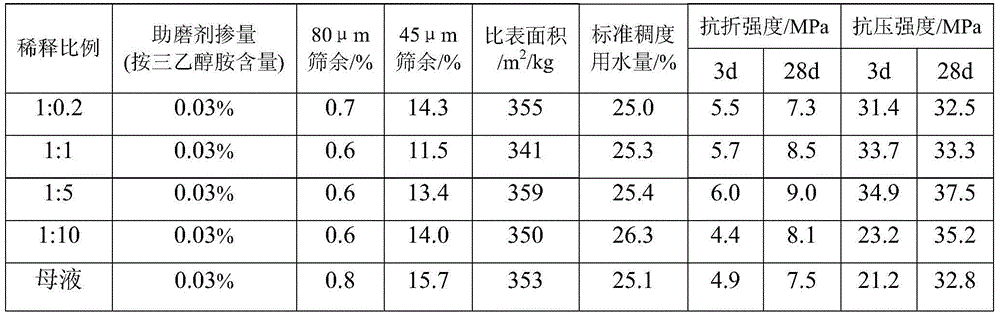

[0020] The performance index results of the tested cement after grinding are shown in Table 1.

[0021] Performance index of cement after table 1 grinding (grinding aid mother liquor triethanolamine: water)

[0022]

Embodiment 2

[0024] A, prepare polycarboxylate grinding aid mother liquor by conventional method;

[0025] B. Dilute the polycarboxylate grinding aid mother liquor and water according to different ratios by volume (1:10 to 1:100) to obtain a dilution;

[0026] C. The diluent is added to the small grinding system of the laboratory, and the cement used is P.O32.5 cement of Esheng Cement Plant, clinker (95%), and gypsum (5%).

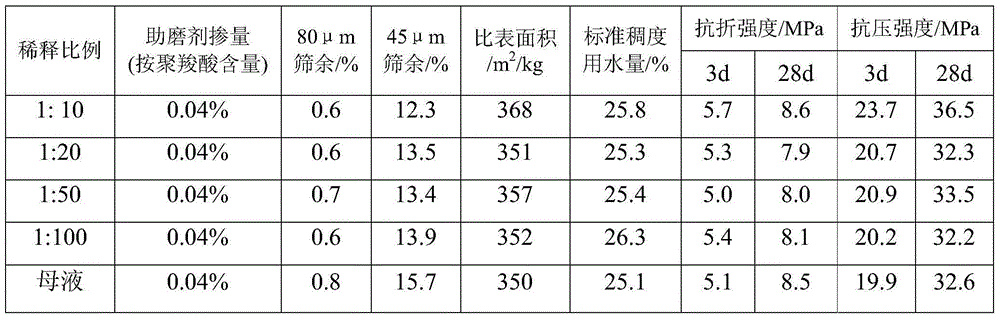

[0027] The performance index results of the tested cement after grinding are shown in Table 2.

[0028] Performance index of cement after table 2 grinding (grinding aid mother liquor polycarboxylate: water)

[0029]

[0030] It can be seen from the above examples that after the technology of the present invention is adopted, the grinding aid mother liquor and the solvent are stirred to obtain a low-concentration grinding aid, and the dispersed grinding aid molecules are more likely to attach to the new surface of the powder, maintaining the dispersion of the partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com