Humic acid controlled release blended fertilizer dedicated for corn

A corn-specific, blended fertilizer technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of the uncoordinated ratio of base fertilizer and top-dressing fertilizer, insufficient fertility in the later stage of planting, improper fertilization method, etc., so as to achieve low production cost and improved utilization. efficiency, reducing waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

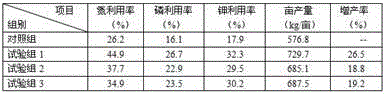

Examples

Embodiment 1

[0024] A humic acid controlled-release blended fertilizer dedicated to corn is composed of the following components in parts by weight: 288 parts of ordinary urea, 165 parts of coated controlled-release urea, 228 parts of monoammonium phosphate, 200 parts of potassium chloride, nitric acid 119 parts of base humic acid. Among them, the mass percentage contents of nitrogen, phosphorus and potassium are respectively 23% (control-release nitrogen accounts for 30%), 10% and 12%, and humic acid is 7%.

[0025] Among them, the mass percentage of N element in monoammonium phosphate is 11%, P 2 o 5 The mass percentage is 44%; K in potassium chloride 2 The mass percentage of O is 60%, the mass percentage of N element in urea is 46%, the mass percentage of N element in coated controlled-release urea is 42%, and the release period is 60-70 days. The mass percentage of acid is 60%, and the mass percentage of N element is 2.5%.

[0026] The preparation method of special humic acid cont...

Embodiment 2

[0029] A humic acid controlled-release blended fertilizer dedicated to corn is composed of the following components in parts by weight: 313 parts of ordinary urea, 179 parts of coated controlled-release urea, 273 parts of monoammonium phosphate, 183 parts of potassium chloride, nitric acid 52 parts of base humic acid. Among them, the mass percentage contents of nitrogen, phosphorus and potassium are respectively 25% (control-release nitrogen accounts for 30%), 12% and 11%, and humic acid is 3%.

[0030] Among them, the mass percentage of N element in monoammonium phosphate is 11%, P 2 o 5 The mass percentage is 44%; K in potassium chloride 2 The mass percentage of O is 60%, the mass percentage of N element in urea is 46%, the mass percentage of N element in coated controlled-release urea is 42%, and the release period is 60-70 days. The mass percentage of acid is 60%, and the mass percentage of N element is 2.5%.

[0031] The preparation method in this example is the same...

Embodiment 3

[0033] A humic acid controlled-release blend fertilizer dedicated to corn is composed of the following components in parts by weight: 322 parts of ordinary urea, 171 parts of coated controlled-release urea, 250 parts of monoammonium phosphate, 167 parts of potassium chloride, nitro 90 parts of humic acid. Among them, the mass percentage contents of nitrogen, phosphorus and potassium are respectively 24% (control-release nitrogen accounts for 30%), 11% and 10%, and humic acid is 5%.

[0034] Among them, the mass percentage of N element in monoammonium phosphate is 11%, P 2 o 5 The mass percentage is 44%; K in potassium chloride 2 The mass percentage of O is 60%, the mass percentage of N element in urea is 46%, the mass percentage of N element in coated controlled-release urea is 42%, and the release period is 60-70 days. The mass percentage of acid is 60%, and the mass percentage of N element is 2.5%.

[0035] The preparation method in this example is the same as that in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com