Production technology of pulp molded cushioning and shockproof packaging products using Enteromorpha

A technology for pulp molding and packaging products, applied in textiles and papermaking, plant raw material addition, secondary cellulose fibers, etc., can solve the problems of wasting natural resources and damaging the environment, and achieve the goals of saving resources, protecting the environment and reducing pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

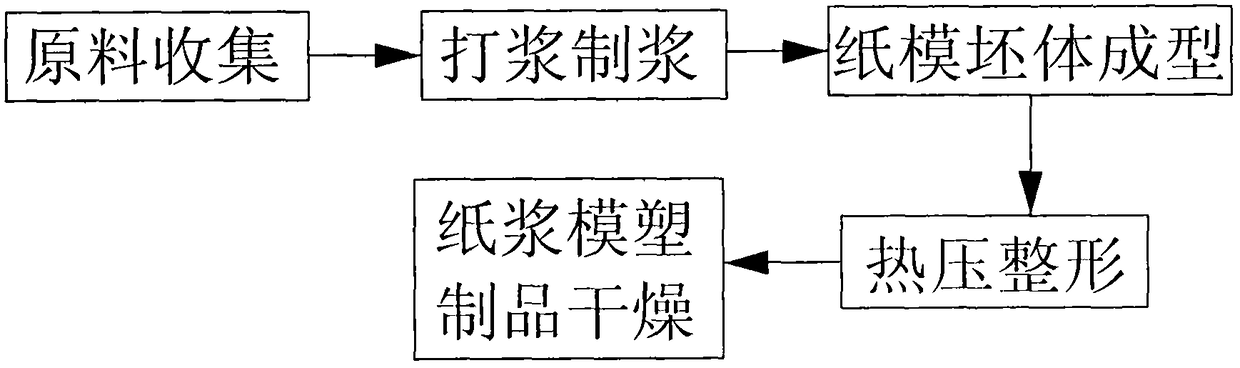

[0026] Such as figure 1 Shown, a kind of production technology that utilizes Enteromorpha to prepare pulp molded cushioning and shockproof packaging products comprises the steps:

[0027] (1) Raw material collection;

[0028] a. Collect waste newspapers, waste carton paper, leftovers from paper mills or printing plants, and reserve them;

[0029] b. The Enteromorpha salvaged from the shore is dehydrated, and the dehydration process can adopt conventional centrifugal dehydration, freeze dehydration or vacuum dehydration, and reserve;

[0030] (2), beating and pulping:

[0031] Put the two spare raw materials in the step (1) into the pulper, and add an appropriate amount of water, and stir the waste paper and Enteromorpha until it becomes a slurry;

[0032] (3) Forming of paper mold body;

[0033] In the pulp tank, the pulp liquid prepared in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com