A urea solution injector

A technology of injector and solution, applied in machine/engine, muffler, engine components, etc., can solve the problem of different key parts, and achieve the effect of inhibiting crystallization, reducing frictional resistance, and avoiding motion stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

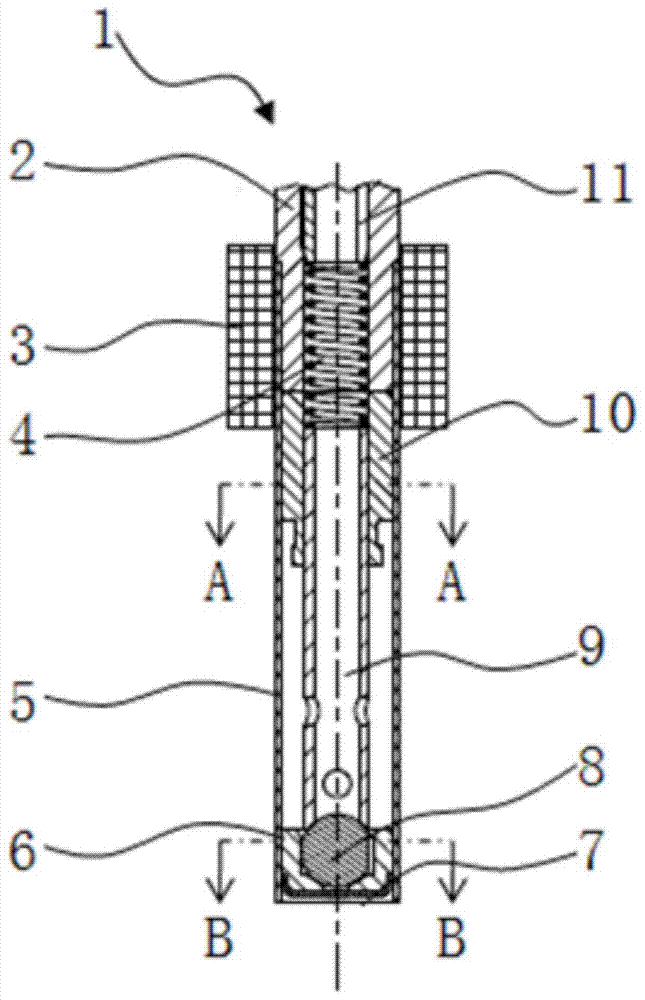

[0021] figure 1 Describe a urea solution injector 1 of a urea solution injector, including a fixed iron core 2, an electromagnetic coil 3, a spring 4, a valve sleeve 5, a valve seat 6, an orifice plate 7, a ball head 8, a valve stem 9, and an armature 10 Wait.

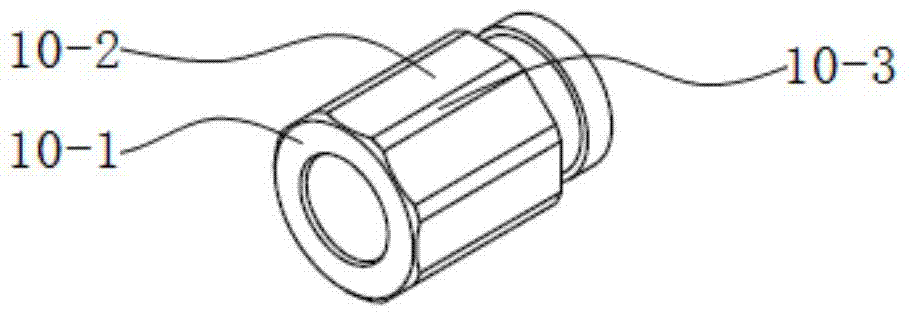

[0022] according to figure 2 , image 3 , Figure 4 , Figure 5 , describing the characteristic structure, heat resistance measures and coating measures of the armature structure of the urea solution injector.

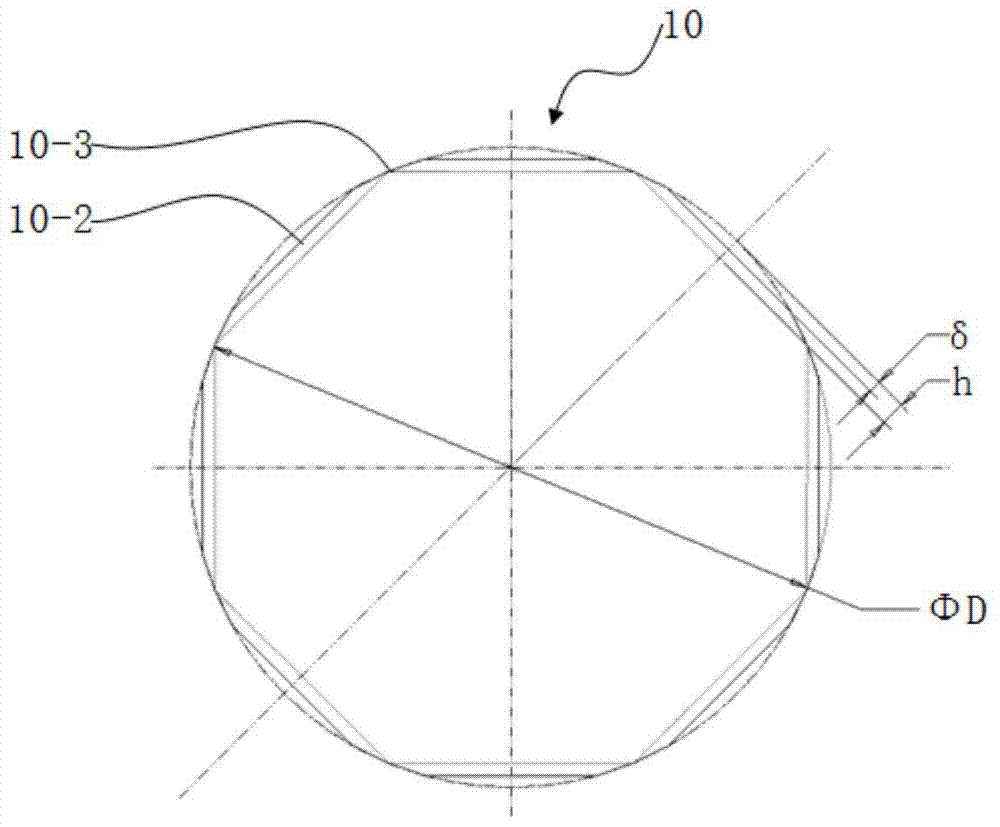

[0023] The guide outer cylinder 10-3 of the armature 10 is processed with evenly distributed multi-faceted parts 10-2, wherein the depth of the cut flat is less than the chord height of the regular octagon inscribed on the circumference of the armature. According to an advantageous structure, figure 2 The multifaceted part 10-2 shown is preferably half of the chord height, and is placed in a thin-walled valve sleeve. The wall thickness of the valve sleeve is preferably 0.3mm, thereby weakening the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com