Composite stiffness damping shock absorber

A technology of compound stiffness and shock absorber, applied in shock absorber, shock absorber-spring combination, shock absorber, etc., can solve problems such as limitation and stiffness short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

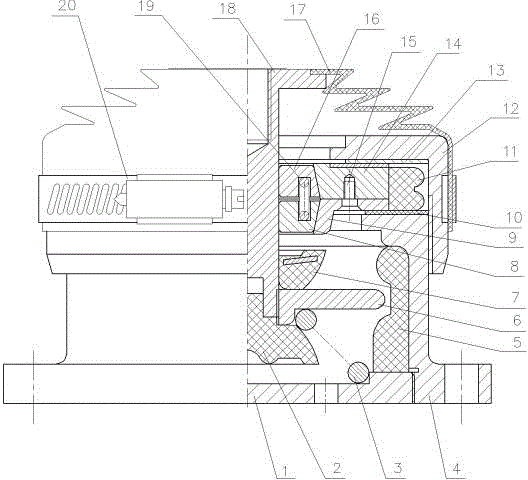

[0023] The composite stiffness damping shock absorber of the present embodiment is as figure 1 As shown, it includes a central axis 18 inserted in the center of the box-shaped base 4 . The upper end of the ring body of the base 1 extends inward to form a top surface with a central through hole, and the upper outer circle of the ring body has an external thread for screwing and fixing the upper cover 12 . The lower end of the base 1 is fixed to the bottom plate 1 by internal threads. Between the flange at the top of the central shaft 18 and the upper cover 12 is a retractable corrugated dust cover 17 fixed by a throat clamp 20 . The upper part of the central shaft 18 is equipped with a Coulomb damper axially constrained between the upper surface of the top plate of the base 4 and the lower surface of the upper cover 12 . The upper and lower friction plates 13 and 10 are respectively lined between the upper and lower end faces of the Coulomb damper and the upper surface of the...

Embodiment 2

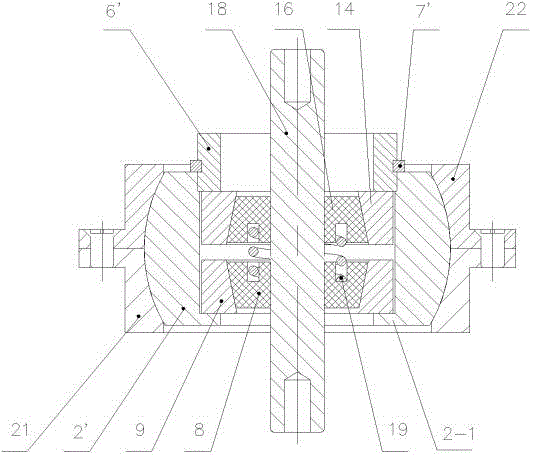

[0031]The basic structure of the composite stiffness damping shock absorber of this embodiment is the same as that of Embodiment 1, the difference is that the upper and lower cone mounting seats 14, 9 of the Coulomb damper are located in the ball seat of the ball hinge structure, and the ball seat is composed of The inner spherical concave is composed of the upper shell 22 and the lower shell 21 and the ball 2' which forms a spherical hinge structure with the upper and lower shells. The center of the ball has an internal thread hole for installing the cone mounting seat. The internal thread One end of the hole has an axial limit shoulder 2-1. The upper and lower cone mounts 14 and 9 have external threads, which are screwed into the internal threads of the center of the sphere 2' at the opposite positions of the large ends of the taper holes, leaving an adjustment interval between them. Position shoulder 2-1, the top surface of the upper cone mounting seat 14 is pressed and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com