A Design Method of Tooth Profile Modification Curve for Tooth Surface Distortion Reduction

A technology of curve design and tooth orientation, which is applied to components with teeth, mechanical equipment, belts/chains/gears, etc., can solve the problems of low processing efficiency, high processing cost, and high requirements for machine tools, and achieve low cost and improved gear The effect of transmission precision and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] According to the mechanism of twisting, when the worm grinding wheel grinds helical gears, the twisting amount at any point at the height can be calculated by calculating the difference between the grinding amount of the tooth top and the tooth root at the same height.

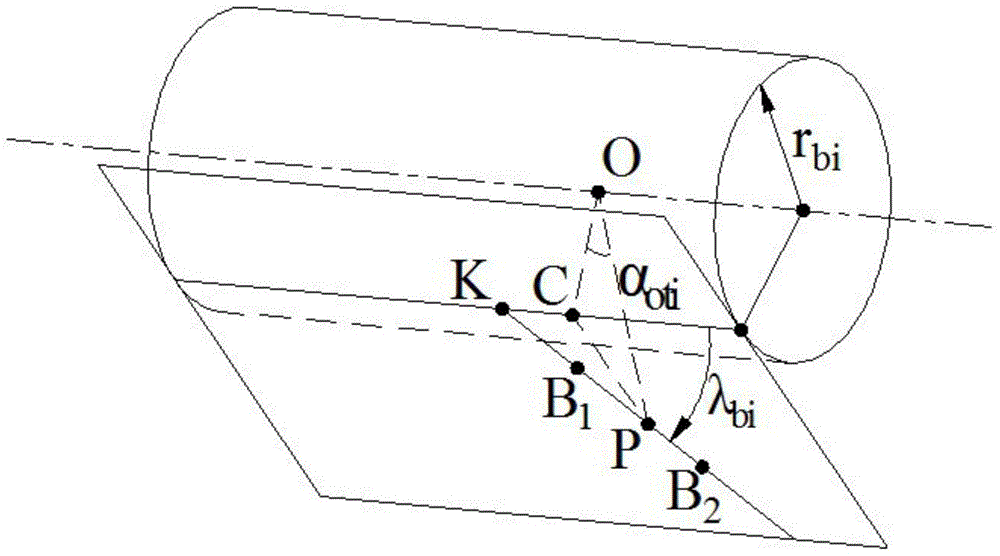

[0019] Such as figure 1 , take a meshing line between the worm wheel and the gear for calculation, and the length of the meshing line is B 1 B 2 .

[0020] B 1 B 2 =PB 1 +PB 2 (1)

[0021] in:

[0022]

[0023]

[0024] In the formula: r bi is the radius of the base circle, α ai is the tangential pressure angle of the addendum circle, α oτi is the tangential pressure angle of the pitch circle, λ bi is the base circle lead angle. i=1 or 2, i=1 represents the worm grinding wheel, and i=2 represents the gear. They can be calculated with formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com