A Ring-Wall Protected Combustion Furnace and Its Numerical Simulation Method for Heat and Mass Transfer

A numerical simulation, heat and mass transfer technology, applied in combustion equipment, electrical digital data processing, lighting and heating equipment, etc. mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

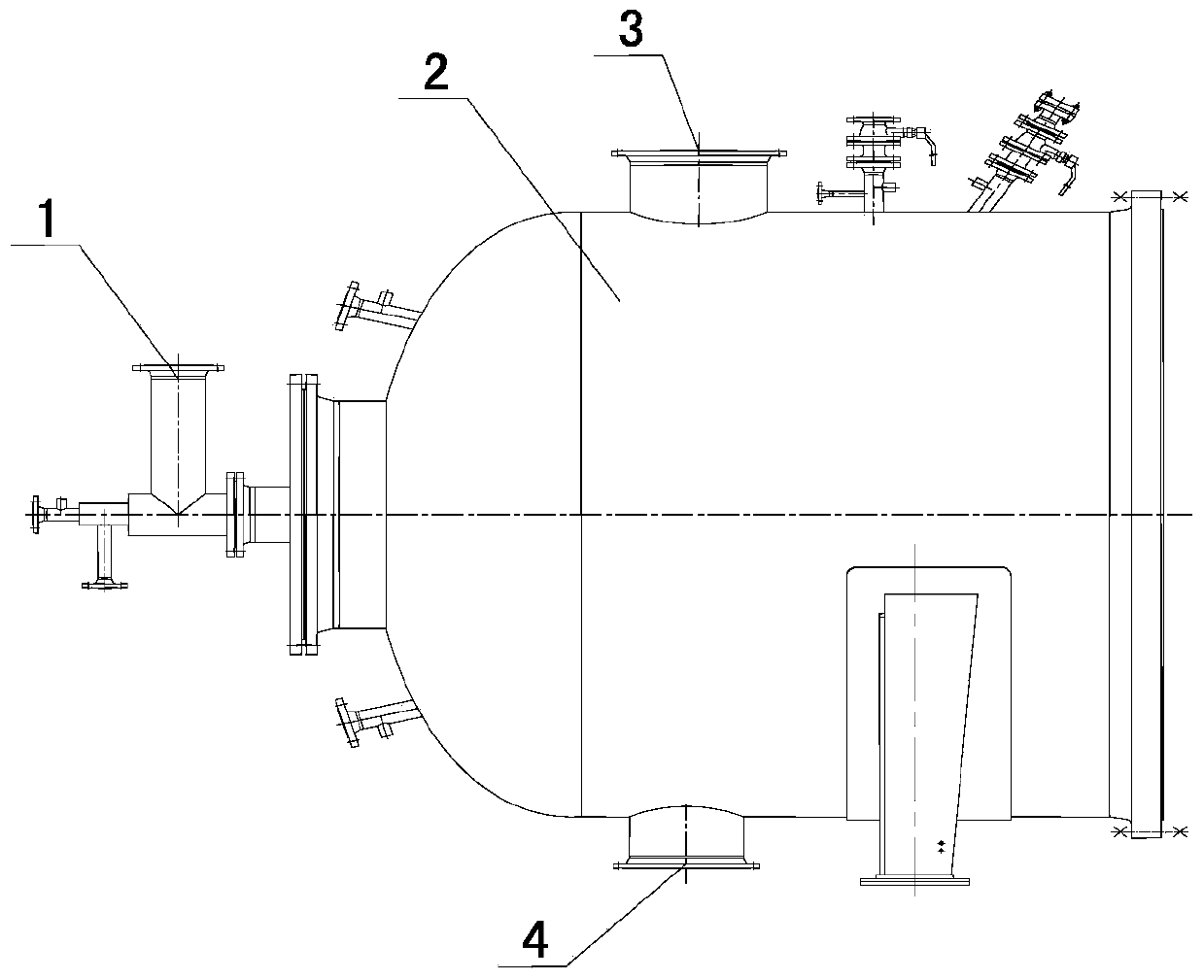

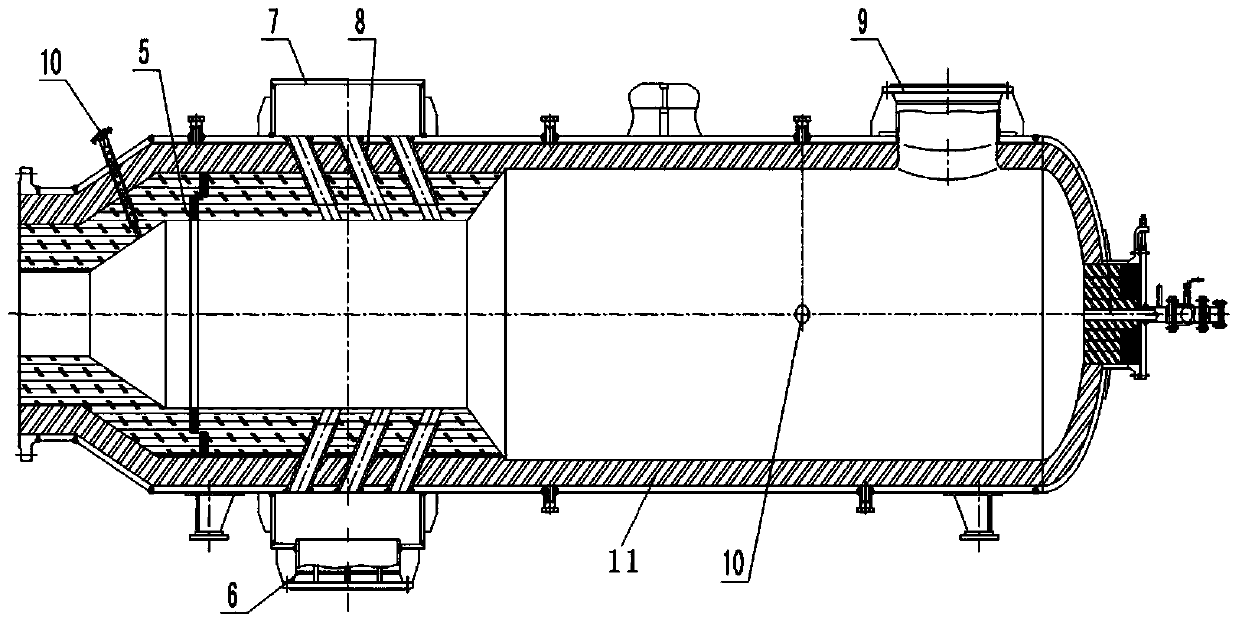

[0034] A ring wall protected combustion furnace, such as figure 1 and figure 2 As shown, it includes: fuel gas inlet 1, burner shell 2, air inlet 3, ring wall protection air inlet 4, refractory and heat-insulating lining 5, process gas inlet 6, process gas inlet ring chamber 7, process gas inlet into the furnace Piping 8, process gas outlet 9, thermometer interface 10, etc., of which:

[0035] A fuel gas inlet 1 is provided at the front end of the burner, a fire-resistant and heat-insulating lining 5 is provided in the burner housing 2, and an air inlet 3, a ring wall protection air inlet 4, and a process gas inlet ring are provided on the burner housing 2. Chamber 7 and process gas outlet 9. A process gas inlet 6 is provided on the process gas inlet ring cavity 7 . A reheated process gas outlet 9 with an upward opening is provided at the tail end of the burner. A thermometer detection interface 10 is provided in the combustion mixing section and the reaction section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com