Pneumatic power amplifier automatic adjusting valve and application thereof

A technology for automatic adjustment of valves and pneumatic power, applied to gas fuel burners, lift valves, valve details, etc., can solve the problems of high cost, easy to be burned, heavy maintenance workload, etc., to achieve long life and save maintenance costs , the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

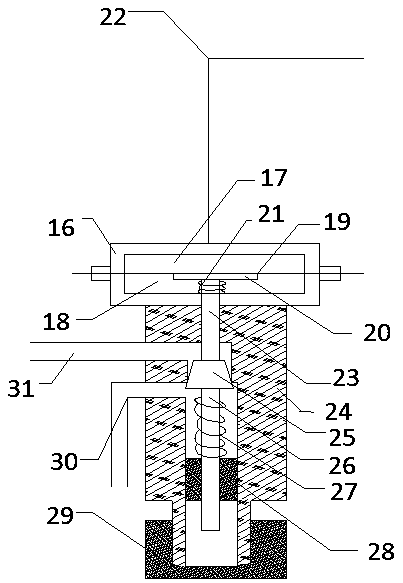

[0033] image 3 It is a structural schematic diagram of the automatic regulating valve of the pneumatic power amplifier described in the present invention.

[0034] Such as image 3 Shown: the pneumatic power amplifier automatic regulating valve, including an air collection unit 16, a gas regulating unit 24 and an adjustment cap 29 arranged in sequence from top to bottom, wherein the air collection unit 16 includes a shell with a hollow cavity inside, a shell A film 19 is arranged on the cross section of the hollow cavity of the body, the cavity (upper chamber 17) at the upper end of the film 19 communicates with the air collection pipe 22, the cavity at the lower end of the film 19 is the lower chamber 18, and in the lower chamber 18 The lower end of the inner membrane 19 is connected to a membrane disc 20, and the lower part of the membrane disc 20 is connected to a pressure shaft 23, and the outer circumference of the pressure shaft 23 between the membrane disc 20 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com