A heat-resistant and heat-absorbing protective structure applied in high-temperature blastholes

A high-temperature blast hole and protective structure technology, which is applied in blasting and other directions, can solve the problems of easy loss of liquid and high potential safety hazards of blasting, and achieve the effects of low cost, low high temperature resistance, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

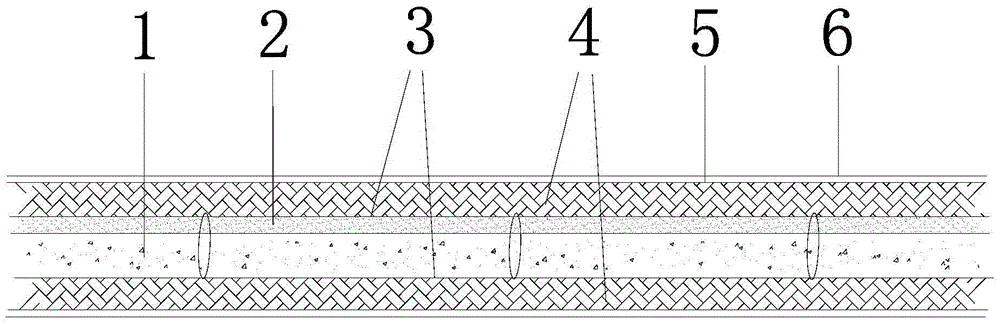

[0033] Such as figure 1 As shown, the heat-resistant and heat-absorbing protection structure of this embodiment includes blasting equipment 1, water-absorbing agent layer 2, water-permeable material layer 3, liquid 4, water-impermeable material layer 5 and fire-resistant and heat-insulating material layer 6, and the water-permeable material layer 3 , the water-absorbing agent layer 2 and the blasting equipment 1 (with a rope) are bundled together, and the overall structure formed by the blasting equipment 1, the water-absorbing agent layer 2 and the water-permeable material layer 3 is packed into the impermeable material layer 5, and the fire-resistant partition The thermal material layer 6 is sleeved on the outer surface of the water-impermeable material layer 5, and the liquid 4 is injected into the gap between the water-permeable material layer 3 and the water-impermeable material layer 5;

[0034] The blasting equipment 1 is a detonating cord, which is located in the cente...

Embodiment 2

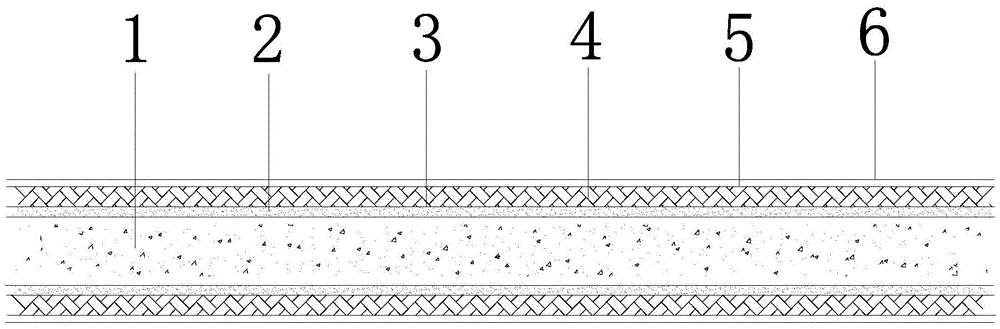

[0046] Such as figure 2 As shown, the heat-resistant and heat-absorbing protection structure of this embodiment includes blasting equipment 1, water-absorbing agent layer 2, water-permeable material layer 3, liquid 4, water-impermeable material layer 5 and fire-resistant and heat-insulating material layer 6, and the water-permeable material layer 3 Wrap the water-absorbing agent layer 2 and the blasting equipment 1 together, and put the overall structure formed by the blasting equipment 1, the water-absorbing agent layer 2 and the water-permeable material layer 3 into the impermeable material layer 5, and the fire-resistant and heat-insulating material layer 6 Sleeved on the outer surface of the water-impermeable material layer 5, the liquid 4 is injected into the gap between the water-permeable material layer 3 and the water-impermeable material layer 5;

[0047] The blasting equipment 1 is a detonating cord with an average diameter of 7-8mm and a length of 5000mm;

[0048]...

Embodiment 3

[0060] Such as figure 2 As shown, the main structure of the heat-resistant and heat-absorbing protection structure of this embodiment is the same as that of Embodiment 2, and its main features are as follows:

[0061] The blasting equipment 1 is No. 2 rock emulsion explosive, its average diameter is 110mm, and its length is 400mm;

[0062] The water-absorbing agent layer 2 is made of super-absorbent resin, and its water-absorbing ratio can reach 100-500 times its own mass;

[0063] The water-permeable material layer 3 is a paper tube, which is made of filter paper, with an inner diameter of 116 mm and a thickness of 0.05 mm;

[0064] The liquid 4 is water, its specific heat capacity is 4.2*103J / (kg·℃), and its boiling point is about 100℃;

[0065] The impermeable material layer 5 is made of polyethylene film, its outer diameter is 132mm, and its thickness is 0.8mm;

[0066] The refractory and heat-insulating material layer 6 is a sleeve made of ceramic fibers; the outer di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com