A kind of preparation method of lead-acid storage battery lead paste mixed with graphene

A lead-acid battery and graphene technology, applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve problems such as difficulty in dispersion, failure to achieve charging and receiving capabilities, high-current charging and discharging performance, and graphene's inability to play, and achieve The effects of prolonging the service life, preventing the sulfation of the negative electrode, improving the charge receiving ability and high current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, a kind of preparation method of the lead-acid storage battery lead paste that is mixed with graphene, it may further comprise the steps:

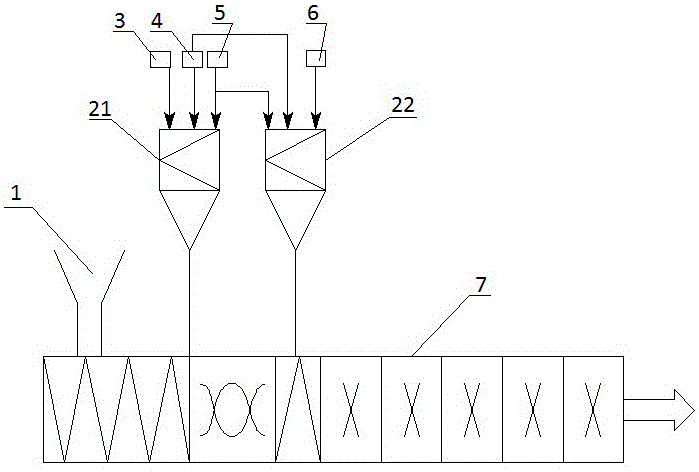

[0017] (1) Weigh 130 grams (1.65 parts) of polyvinylpyrrolidone PVP, sodium carboxymethylcellulose CMC, sodium lignosulfonate SLS or sodium dodecylbenzenesulfonate SDBS and add 8 kg (100 parts) of deionized In water and stir evenly in the high-speed stirring disperser 21, slowly add graphene powder containing 100 grams (1.25 parts) of pure graphene under stirring, the graphene average sheet thickness of the graphene powder is 3nm, and the content is 80%. The solution obtained after stirring for 5 minutes is the graphene aqueous dispersion. 3 is the feeding device of deionized water, 4 is the feeding device of aqueous dispersant, and 5 is the feeding device of graphene.

[0018] (2) Weigh 4 kg (40 parts) of sulfuric acid with a concentration of 98% and slowly add 10 kg (100 parts) of deionized water along the container ...

Embodiment 2

[0025] Embodiment 2, a kind of preparation method of the lead-acid storage battery lead paste that is mixed with graphene, it may further comprise the steps:

[0026] (1) Weigh 15 grams (0.1 part) of two of polyvinylpyrrolidone PVP, sodium carboxymethylcellulose CMC, sodium lignosulfonate SLS and sodium dodecylbenzenesulfonate SDBS and add 15 kilograms (100 part) deionized water and stir evenly in the high-speed stirring disperser 21, slowly add graphene powder containing 60 grams (0.5 parts) of pure graphene under stirring, the graphene average sheet thickness of the graphene powder is 1nm, The content is 99%, and the solution obtained after stirring for 5 minutes is the graphene aqueous dispersion. 3 is the feeding device of deionized water, 4 is the feeding device of aqueous dispersant, and 5 is the feeding device of graphene.

[0027](2) Weigh 3 kg (130 parts) of sulfuric acid with a concentration of 98% and slowly add 2.3 kg (100 parts) of deionized water along the conta...

Embodiment 3

[0033] Embodiment 3, a kind of preparation method of the lead-acid storage battery lead paste that incorporates graphene, it may further comprise the steps:

[0034] (1) Weigh 330 grams (3 parts) of three kinds of polyvinylpyrrolidone PVP, sodium carboxymethylcellulose CMC, sodium lignosulfonate SLS and sodium dodecylbenzenesulfonate SDBS and add 11 kilograms (100 part) in deionized water and stir evenly in the high-speed stirring disperser 21, slowly add graphene microflake powder containing 550 grams (5 parts) of pure graphene under stirring, the graphene microflake powder of this graphene microchip powder The average sheet thickness is 20nm, the content is 99.5%, and the solution obtained after stirring for 5 minutes is the graphene aqueous dispersion. 3 is the feeding device of deionized water, 4 is the feeding device of aqueous dispersant, and 5 is the feeding device of graphene.

[0035] (2) Weigh 4 kg (51 parts) of sulfuric acid with a concentration of 98% and slowly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com