Spine screw

A screw and spine technology, applied in the field of bone anchor devices in spinal repair, can solve problems such as screw breakage, and achieve the effects of facilitating removal of broken screws, reducing bone damage, and facilitating revision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The split-type spinal screw of the present invention will be further described in detail through specific embodiments below.

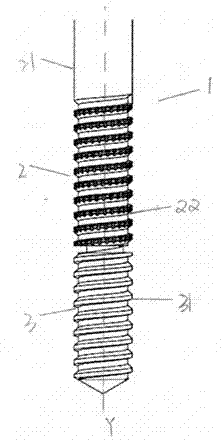

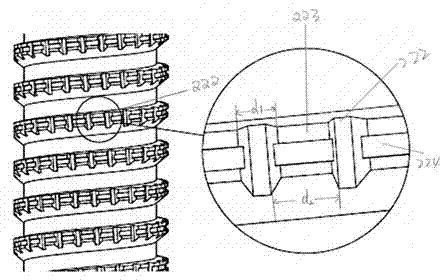

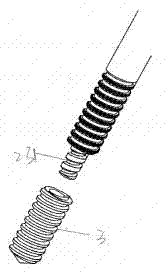

[0025] Such as Figure 1-3 As shown, the body 1 is the main body of a split-type pedicle screw, which defines the longitudinal axis Y, and the body is made of titanium alloy or PEEK material. The split-type screw includes an upper segment 2 and a lower segment 3 (integrated with cortical bone and cancellous bone respectively ), the upper section 2 includes a head portion 21, a rod portion 22, and a tail portion 23. The rod portion 22 has a first thread structure 221, and the first thread structure is provided with interval grooves 222 along the longitudinal direction. The grooved The shape can be trapezoidal groove, rectangular groove, or curved groove. Such as figure 2 As shown, the corresponding thread protrusion 223 is arranged adjacent to the groove, and the protrusion here is relative to the groove, that is, the distance between the toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com