A glaze storage cylinder with diversified functions and a method for improving the performance of glaze slurry

A glaze jar and function technology, which is applied to the glaze storage jar with various functions and the fields of improving the performance of the glaze slurry, can solve the problems such as the influence of the stability of the flow rate of the glaze slurry, the difficulty of discharging small air bubbles, and the product defects, so as to improve the glaze slurry. Performance, simple structure, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

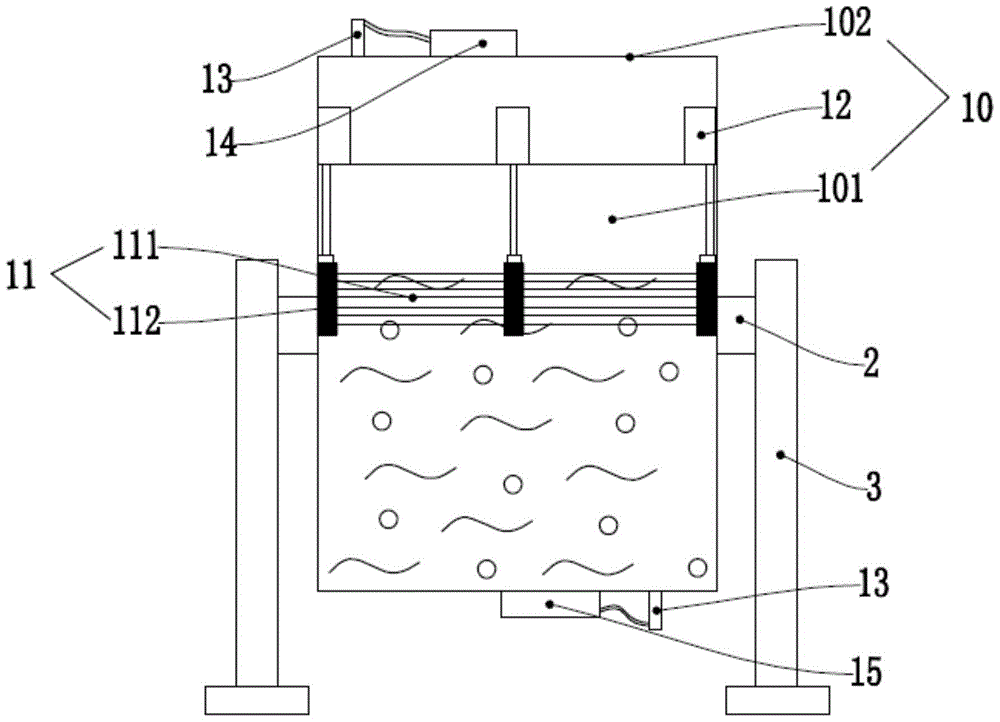

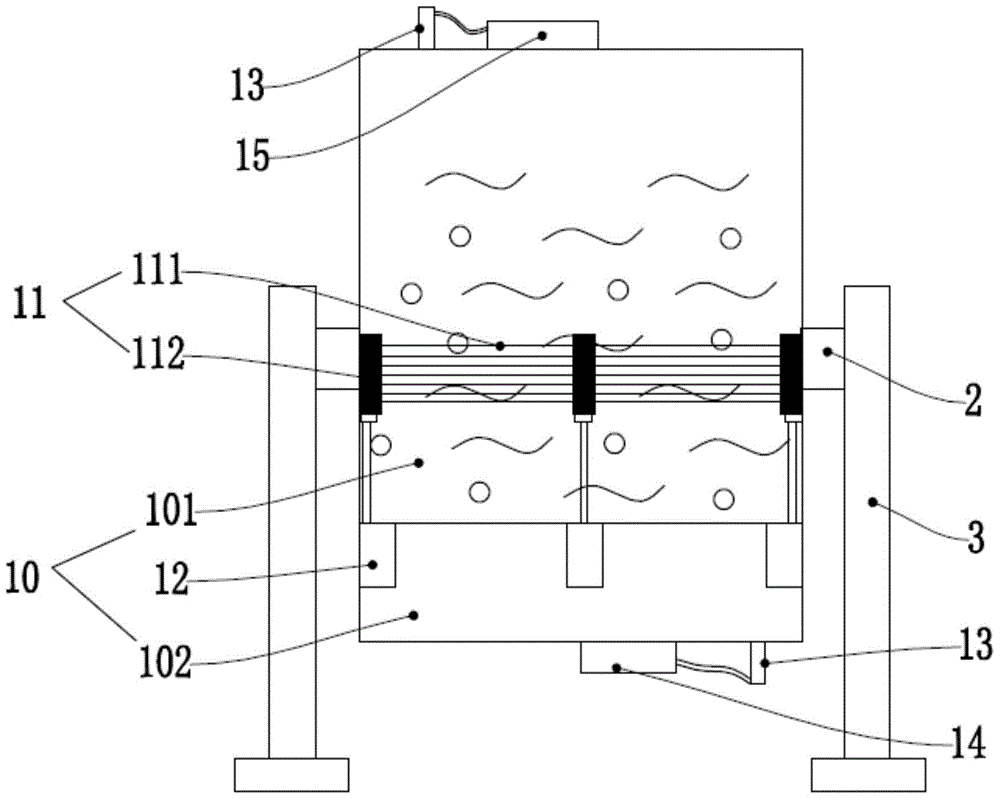

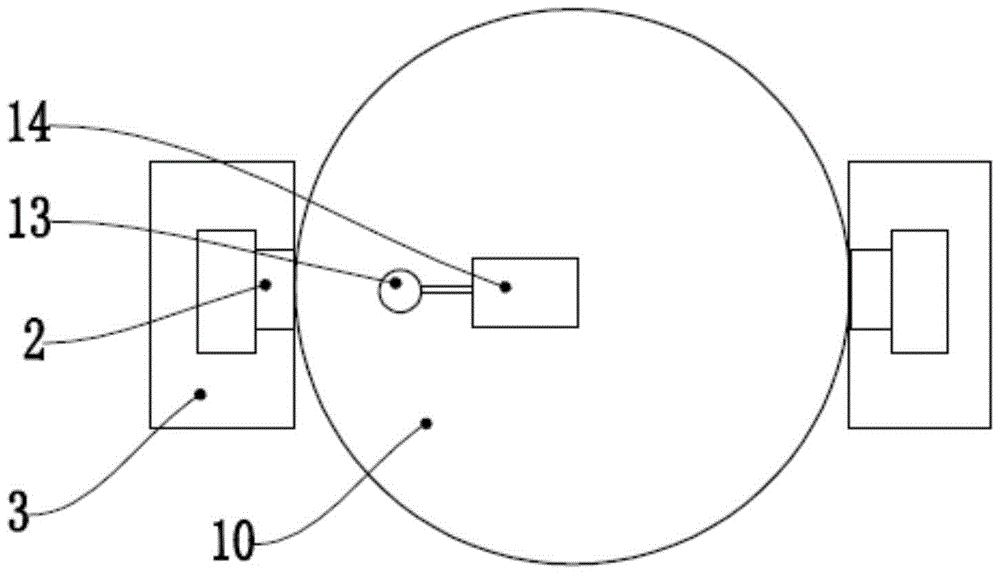

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0029] Such as Figure 1-3 As shown, a glaze storage vat with diversified functions includes a glaze storage vat 1, a turning mechanism 2 and a base 3, and the glaze storage vat 1 is rotatably mounted on the base 3 through the turning mechanism 2;

[0030] The glaze storage cylinder 1 includes a screen device 11, a screen ejector device 12 and an inlet and outlet 13;

[0031] The screen device 13 is movably clamped in the inner cavity of the glaze storage tank 1 and separates the inner cavity to form two or more spaces with the same cross-section. Spaces are connected through screens;

[0032] The screen pushing device 12 is installed on the inner wall of the glaze storage cylinder 1, and its pushing top is connected to the screen device 11 and provides push-pull force to the screen device 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com