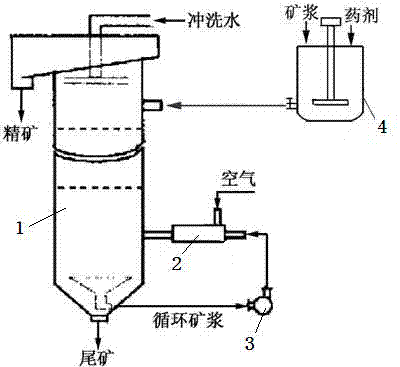

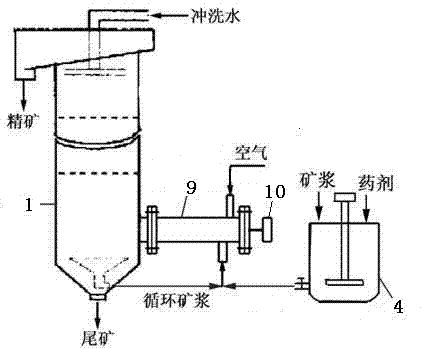

Novel flotation column and flotation method thereof

A flotation column, a new type of technology, applied in flotation, solid separation, etc., can solve the problems of pipeline blockage, increase manufacturing cost, unfavorable collophosite flotation, etc., achieve the effect of easy operation and control, and reduce installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

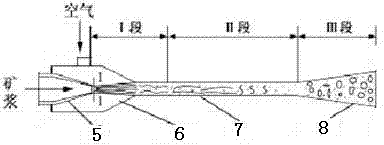

Method used

Image

Examples

example 1

[0036] Example 1: use the flotation column of the present invention to reverse flotation Guizhou Weng'an high-magnesium phosphate rock, containing P in the ore 2 o 5 Under the conditions of 23.15% and MgO 5.21%, the P-containing 2 o 5 With 30.07% phosphorous concentrate, the recovery rate of P2O5 can reach 87.69%. Compared with the sorting index of flotation machine under similar conditions, phosphorus concentrate P 2 o 5 The grade increased by 0.42%, the recovery rate increased by 7.85%, and the amount of collector decreased by 20%. The relevant flotation separation results are shown in Table 1.

[0037] Table 1 Results of flotation comparison test of Weng'an phosphate rock

[0038]

example 2

[0039] Example 2: use the flotation column of the present invention to reverse flotation Hubei Shenlongjia high-magnesium phosphate rock, containing P in the ore 2 o 5 23.37%, MgO5.83%, using a single reverse flotation process, can obtain phosphorus concentrate P 2 o 5 The grade is 31.74%, and the flotation index of P2O5 recovery rate is 86.09%. Compared with the sorting index of flotation machine under similar conditions, P 2 o 5 The grade increased by 1.03%, the recovery rate increased by 5.14%, and the amount of collector decreased by 20%. The relevant flotation separation results are shown in Table 2.

[0040] Table 2 Shenlongjia phosphate rock flotation comparison test results

[0041]

[0042] Experimental research shows that the main equipment parameters that affect the flotation performance of the flotation column of the present invention are its rotational speed, circulating slurry flow rate and aeration volume. The ore properties of flotation phosphate rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com