Application of ball milling immobilization method in treatment of heavy metal contaminated soil

A technology for contaminated soil and heavy metals, which is applied in the field of heavy metal-contaminated soil, can solve problems such as poor soil remediation technology effects, and achieve the effect of improving the refinement effect, simple and fast operation, and reducing the noise coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

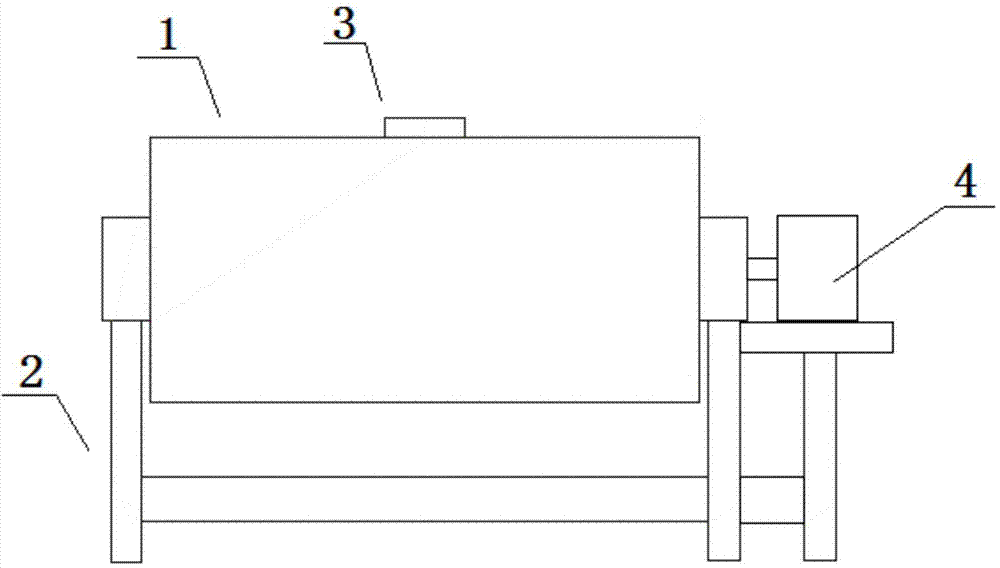

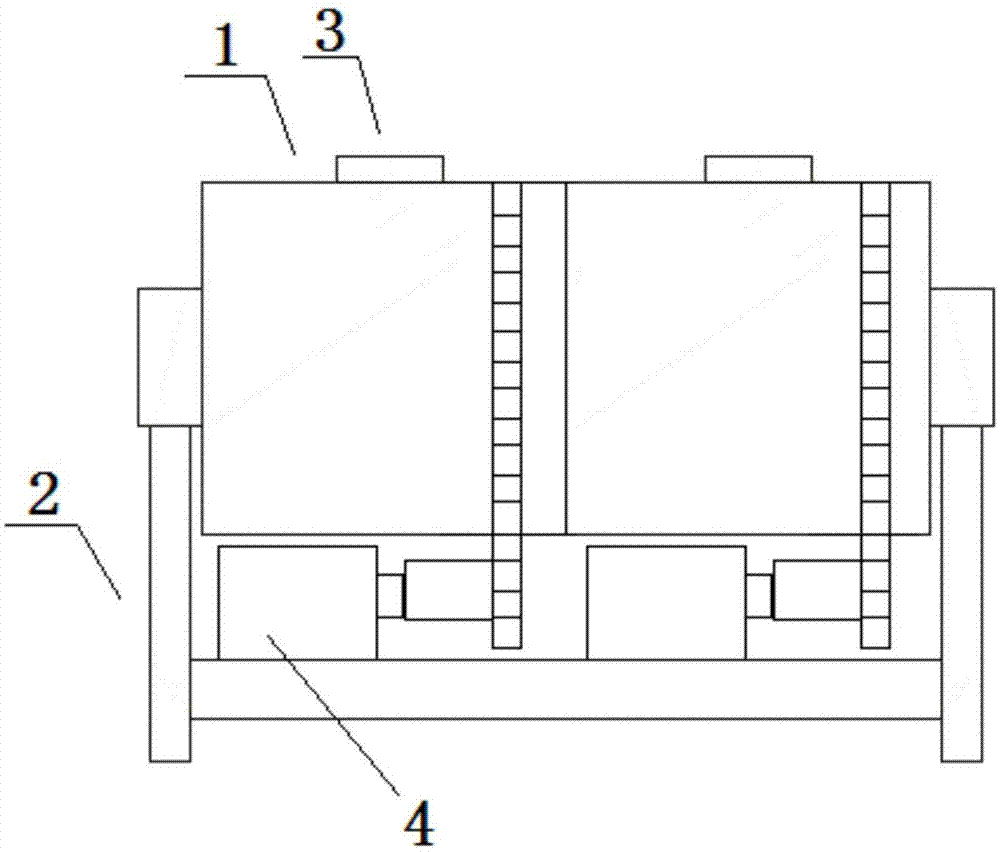

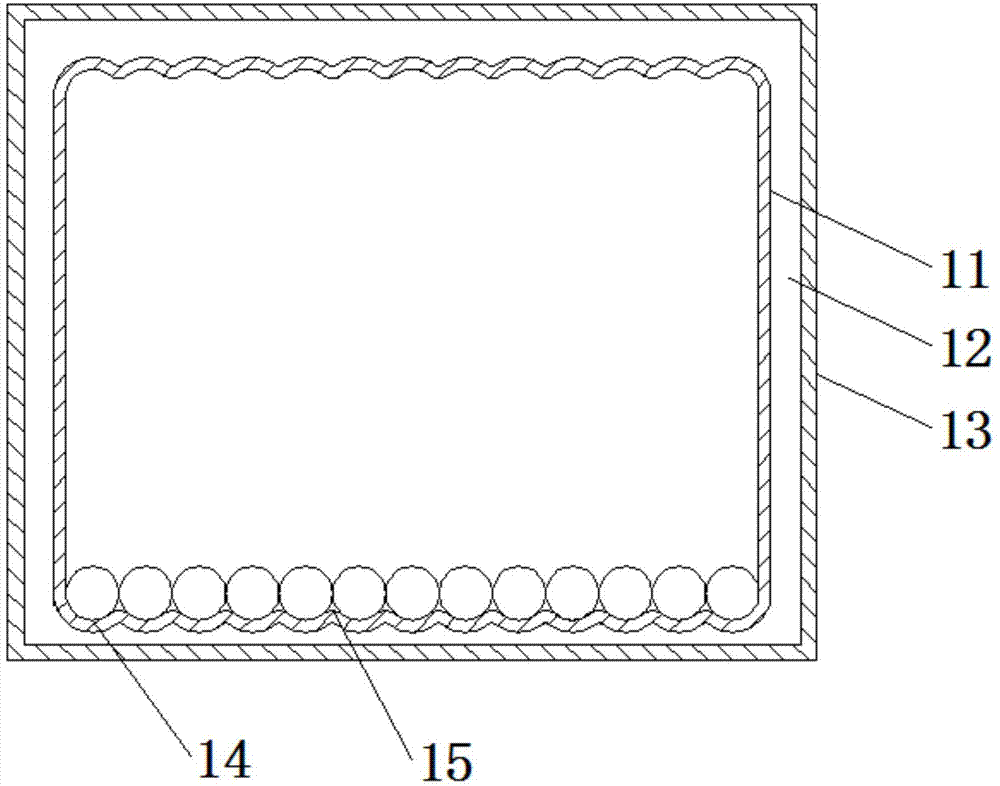

[0058]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

[0059] refer to figure 1 , figure 2 , image 3 , the application of the ball milling solidification method in the treatment of heavy metal contaminated soil, the ball milling solidification method is used to repair the heavy metal contaminated soil containing nickel, zinc, arsenic, lead, copper, the following specific steps for the restoration of heavy metal contaminated soil: Step 1. Use excavation The machine excavates the heavy metal-contaminated soil, and the excavated polluted soil is screened and separated by particle size; step 2. screens and separates the heavy metal-contaminated soil with a particle diameter not greater than 2mm, and uses a ball mill to grind the heavy metal-contaminated soil; step 3. grinds Add a mixed reagent for curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com