Hydraulic retarder for heavy truck axle

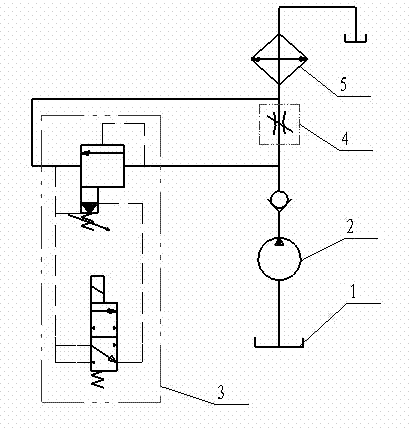

A retarder and hydraulic technology, which is applied in the direction of brakes, vehicle parts, brake components, etc., can solve the problems of poor braking performance of vehicles, achieve the effects of improving braking capacity, saving connection space, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

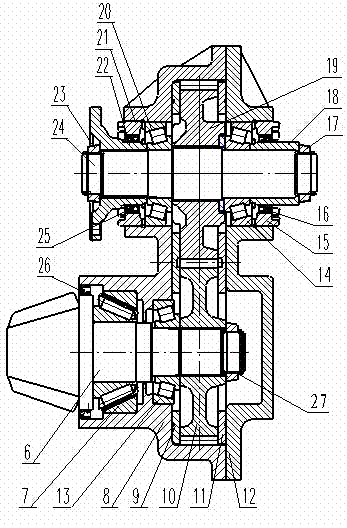

[0015] Example 1, see figure 1 , 2 According to the design requirements, each part is processed and made, and the driving bevel gear shaft 6 is connected with the driving cylindrical gear 10 through a spline to drive the driving cylindrical gear 10 to rotate, and the driving cylindrical gear 10 and the driven cylindrical gear 19 are meshed and transmitted in the housing 8 , the first floating side plate 9 and the second floating side plate 11 are respectively installed on the two ends of the driving cylindrical gear 10 to realize automatic compensation of the end face gap and ensure the sealing of the end face; the housing 8 and the upper cover 12 are connected together by bolts, Ensure the clearance between the first floating side plate 9 and the second floating side plate 11 and the gear end face; connect the driven cylindrical gear 19 with the driven shaft 24 through a spline to drive the driven shaft 24 to rotate; the driven shaft 24 and the flange 22 Through the spline c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com