Coated wave-absorbing material prepared from nano-graphite powder and preparation method of coated wave-absorbing material

A technology of nano-graphite powder and wave-absorbing materials, which is applied in the field of wave-absorbing materials, can solve the problems of complex preparation process, incapable of industrialized preparation, and high cost, and achieve the effects of improved wave-absorbing performance, light weight, and strong wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

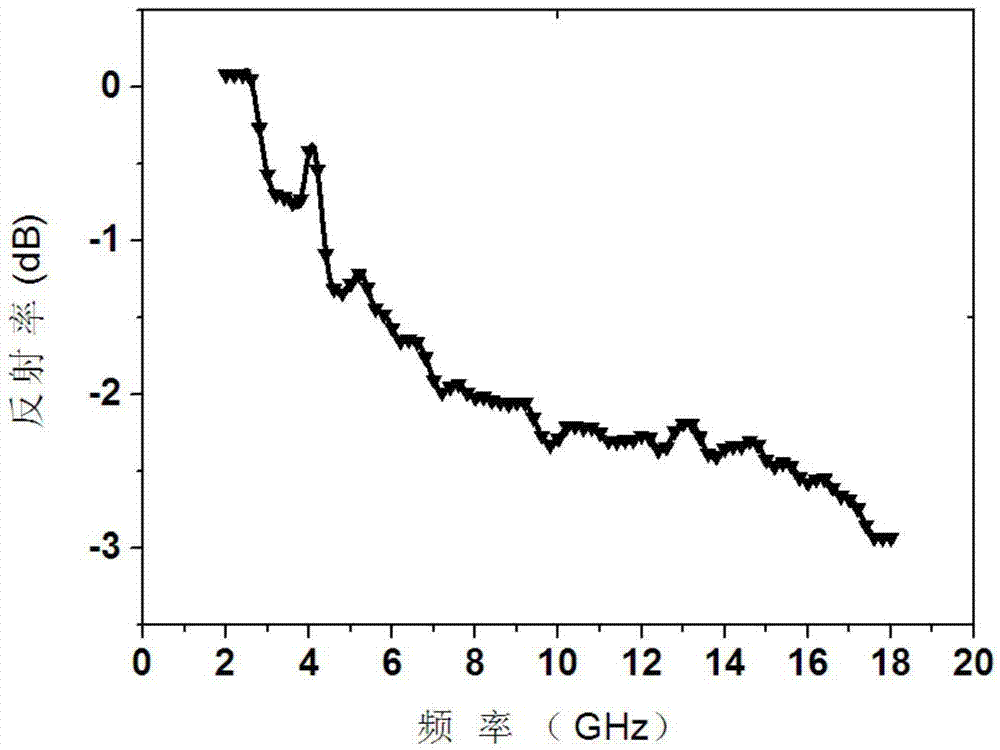

[0028] Mix the dried nano-graphite powder (particle size is 100nm) with polypropylene, wherein the weight percentage of nano-graphite powder is 1%, and the weight percentage of polypropylene is 99%. A thin slice of 20cm×20cm×2mm was prepared by this method. The maximum reflectance of this sheet test is -3dB (see figure 1 ).

Embodiment 2

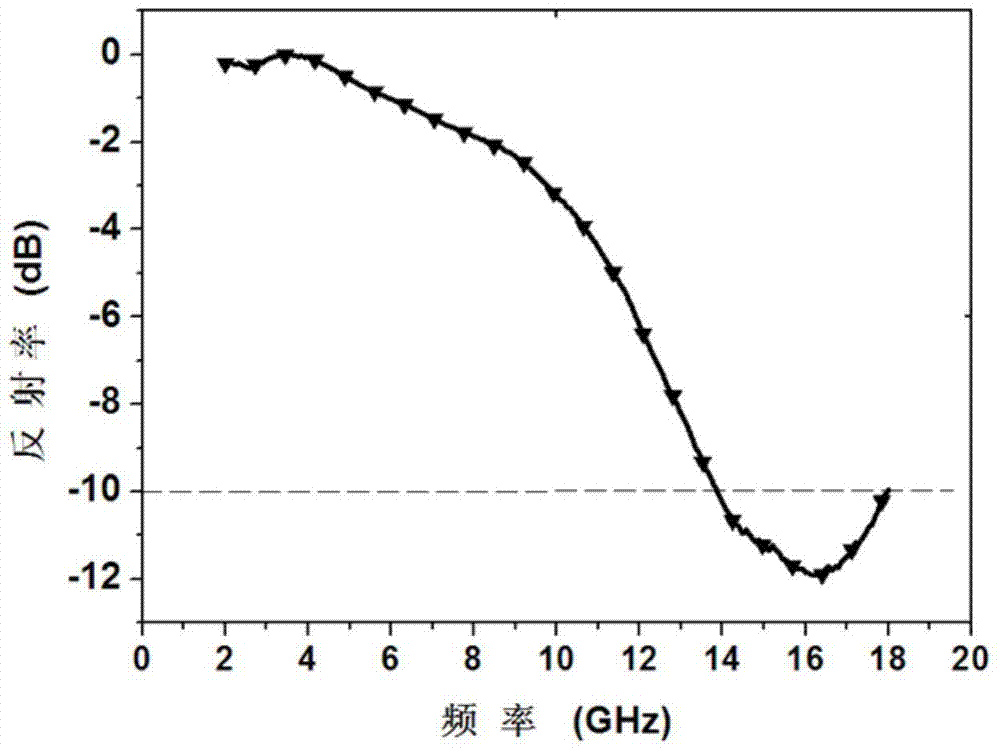

[0030] Mix the dried nano-graphite powder (particle size is 100nm) with epoxy resin, wherein the nano-graphite powder weight percentage is 5%, and the epoxy resin weight percentage is 95%, after uniformly mixing by mixer, use A thin slice of 20cm×20cm×2mm was prepared by brushing. This sheet has a peak at 16.16GHz, the reflectivity is -11.92dB, and the absorbing bandwidth less than -10dB is 4.1GHz (see figure 2 ).

Embodiment 3

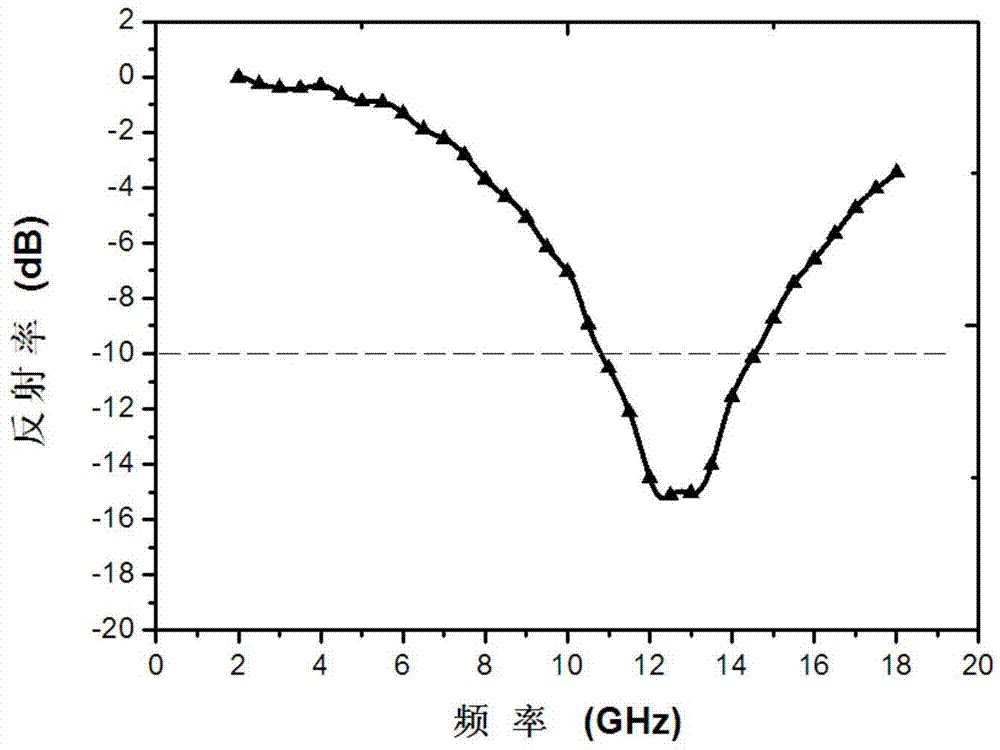

[0032] The nano-graphite powder (particle size is 200nm) after the drying process is mixed with epoxy resin, wherein the nano-graphite powder weight percentage is 15%, and the epoxy resin weight percentage is 85%. A thin slice of 20cm×20cm×2mm was prepared by brushing. This sheet has a peak at 12.64GHz, the reflectivity is -15dB, and the absorbing bandwidth less than -10dB is 3.8GHz (see image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com